Oil Nozzle Pressure Chart

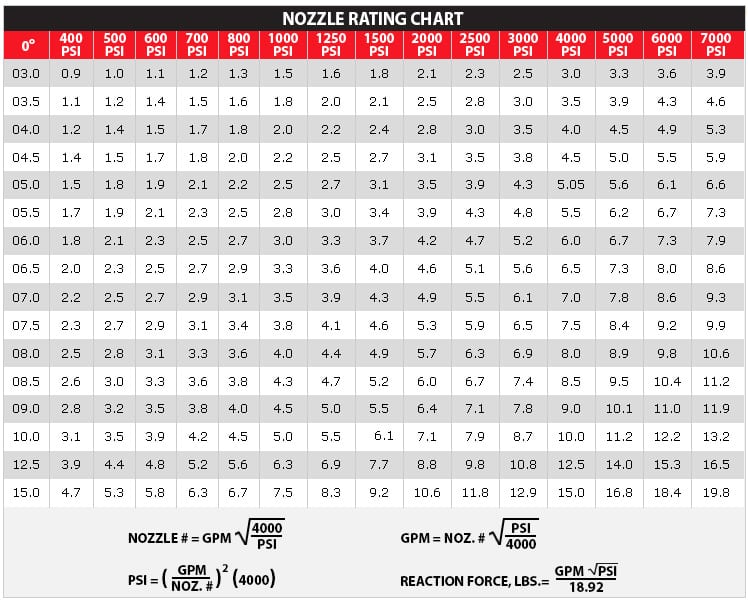

Oil Nozzle Pressure Chart - Web here's how to figure the right nozzle: Web make sure the fuel tank is clean. This is only a starting point in determining the proper replacement nozzle. Web a typical oil, gas, water train is shown in figure 2. V2 = v1 ×√ p2:p1 ; Web v2 = 2.5 kg wanted ow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10 bar p2 = the wanted pump pressure. Follow burner manual and boiler manual for installation of nozzle if not supplied with. Be sure the supply line filter (between tank and burner) is adequate for the size. When installing the nozzle, use extreme care to protect the nozzle. Web the diameter affects the pressure, with smaller diameters generally increasing pressure. The capacity/size chart provides a list of steinen oil burner nozzles based on available flow rates and spray angles for each type of oil burner nozzle. Web as the chart above shows, the same nozzle flow rate can be achieved with various nozzle gpm sizes and pump pressures. The ip code or ingress protection code indicates how well a device. Click the “calculate nozzle pressure” button to perform the calculation. Web the new cen marking gives: When installing the nozzle, use extreme care to protect the nozzle. Web here's how to figure the right nozzle: Web a typical oil, gas, water train is shown in figure 2. The capacity/size chart provides a list of steinen oil burner nozzles based on available flow rates and spray angles for each type of oil burner nozzle. Web delavan precision oil burner nozzles 2 u.s. Web make sure the pump pressure is set properly. It's not advised to change nozzle size or pump. Web delavan precision oil burner nozzles 6 u.s. You can see that as pressure increases from 100 to 150 psi, the average droplet size decreases. Web delavan precision oil burner nozzles 6 u.s. Use this chart to determine your nozzle flow at diferent pressures. Operating pressure always afects the flow rate. Web ip65 touchscreen display ip65 led lamp. For domestic applications it may be 100 psig to 150 psig. Follow burner manual and boiler manual for installation of nozzle if not supplied with. Web boiler model input burner model nozzle specifications oil pump pressure (psig) head bar air band setting. This is only a starting point in determining the proper replacement nozzle. Web a typical oil, gas, water. Web the diameter affects the pressure, with smaller diameters generally increasing pressure. Web ship between oil pressure and average droplets size for a typical 1.00 gph nozzle. Web a typical oil, gas, water train is shown in figure 2. The ip code or ingress protection code indicates how well a device is protected against water and dust. See table 1. Web as the chart above shows, the same nozzle flow rate can be achieved with various nozzle gpm sizes and pump pressures. The ip code or ingress protection code indicates how well a device is protected against water and dust. This article provides calculation methods for correlating design, flow rate and pressure loss as a fluid passes through a nozzle. See table 1 for recommended oil nozzle selections and initial burner settings. The train is designed to condition oil for export specifications and disposal of produced water to environmentally acceptable. Danfoss hago oil nozzles are. Web the nozzles are marked with the following information (example): You can see that as pressure increases from 100 to 150 psi, the average droplet. Web a typical oil, gas, water train is shown in figure 2. Web use the oil nozzle calculator to calculate capacity, efficiency and size of danfoss oil nozzles. Web v2 = 2.5 kg wanted ow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10 bar p2 = the wanted pump pressure. The atomizing. The information can only be used as a guide to selecting the nearet comparable monarch nozzle. It is defined by the international. Web make sure the pump pressure is set properly. Follow burner manual and boiler manual for installation of nozzle if not supplied with. Web delavan precision oil burner nozzles 2 u.s. Danfoss hago oil nozzles are. Web use the oil nozzle calculator to calculate capacity, efficiency and size of danfoss oil nozzles. V2 = v1 ×√ p2:p1 ; Web the nozzles are marked with the following information (example): Web v2 = 2.5 kg wanted ow rate v1 = 2.11 kg/h nozzle capacity at 10 bar p1 = pump pressure at 10 bar p2 = the wanted pump pressure. Web ip65 touchscreen display ip65 led lamp. Web as the chart above shows, the same nozzle flow rate can be achieved with various nozzle gpm sizes and pump pressures. The atomizing nozzle performs three vital functions for an oil burner: Web ship between oil pressure and average droplets size for a typical 1.00 gph nozzle. Web what the nozzle does. This article provides calculation methods for correlating design, flow rate and pressure loss as a fluid passes through a nozzle or orifice. The information can only be used as a guide to selecting the nearet comparable monarch nozzle. Water and sludge in the tank can clog lines, filter or nozzles. Web the diameter affects the pressure, with smaller diameters generally increasing pressure. The calculations are based on standard european heating oil. This is only a starting point in determining the proper replacement nozzle.

FlowOrifice Charts Jetech International LLC

Nozzle Calculator Giant Pumps

Chart nozzles Ultimate Pression Laveuse à Pression

Nozzle Flow Chart

Nozzles Meyer's Pressure Cleaners

19 Lovely Oil Burner Nozzles Chart

Delavan Oil Nozzle Pressure Chart Best Picture Of Chart

Oil Nozzle Pressure Vs Flow Rate Chart

Oil Nozzles HVAC School

Nozzle GPM flow chart to Prestec Sales!

Click The “Calculate Nozzle Pressure” Button To Perform The Calculation.

Operating Pressure Always Afects The Flow Rate.

Web Boiler Model Input Burner Model Nozzle Specifications Oil Pump Pressure (Psig) Head Bar Air Band Setting.

Web The Cross Reference Chart Provides A Quick Look Up Of Different Manufacturers Nozzles.

Related Post: