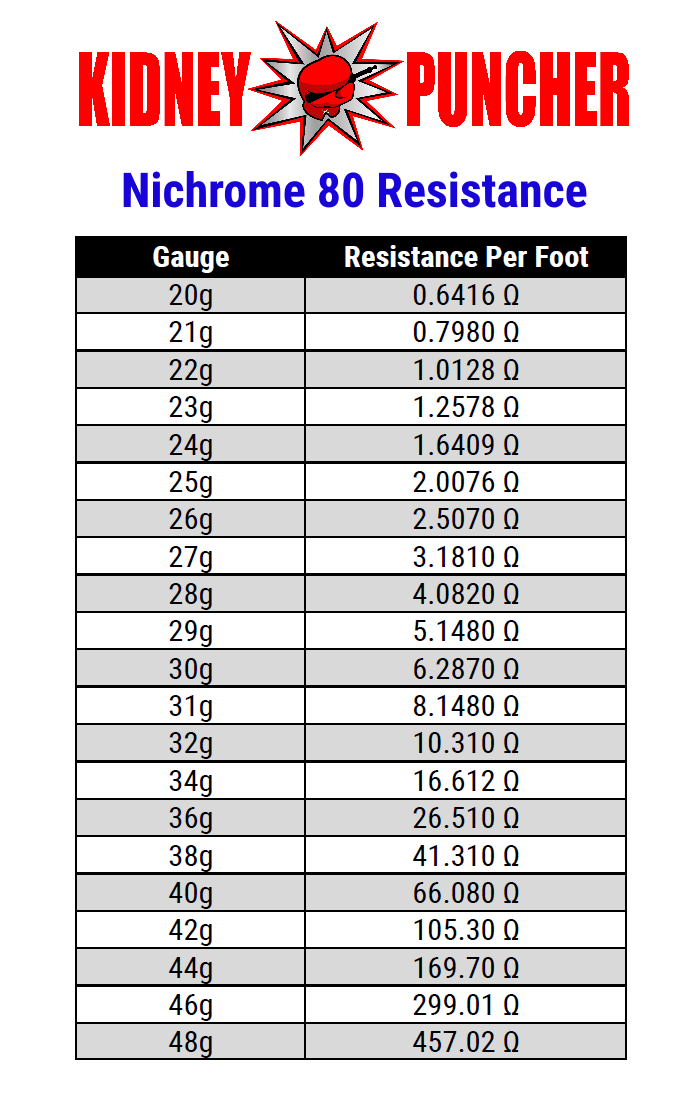

Nichrome 80 Resistance Chart

Nichrome 80 Resistance Chart - It has good ductility after use and excellent weldability. It is ideally suited as a resistance wire heating alloy. Materials for electric heating depend upon an inherent resis tance to the flow of electricity to generate heat. Web omegatm nic80 wire is a resistance heating wire comprised of 80% nickel and 20% chromium. Nic80 wire is commonly used as a resistor at elevated temperatures. It has highly corrosion resistance and lower coefficient of resistance than other heater element alloys. Nichrome 80 is the most ideal resistance heating alloy. Compare the properties and specifications of different gauges and diameters of alloy 650 wire. Nichrome 60 wire is generally used to manufacture electrical resistance for insulated and open appliances. Due to its ductibility and strength at high temperature, nichrome 80 is especially suitable for applications in the electrical appliance industry. This is used for electrical cooking equipment, precison resistors. Web nichrome 80 (uns n06003 / w.nr. Web omegatm nic80 wire is a resistance heating wire comprised of 80% nickel and 20% chromium. Wire temperature 500 o c. Nichrome 80 (uns n06003/2.4869) is a high grade austenitic alloy. Web omegatm nic80 wire is a resistance heating wire comprised of 80% nickel and 20% chromium. It is ideally suited as a resistance wire heating alloy. + add to project list. Web nichrome 80 (uns n06003 / w.nr. Web nicr 80:20 is suitable for heating elements used for temperatures upto 1200°c. Lead time (if not in stock): Web introduction to resistance heating alloys. Web niwire industries is a manufacturer of nickel alloys, duplex, super duplex steels, 6% moly and other special stainless steels. Web nicr 80:20 is suitable for heating elements used for temperatures upto 1200°c. Nic80 wire is commonly used as a resistor at elevated temperatures. This is used for electrical cooking equipment, precison resistors. Withstands high temperatures up to 2100°f. Web nichrome 80 (uns n06003 / w.nr. Our nichrome wire has an appreciable temperature rating of 1177°c (2150°f), is corrosion resistant, and resists oxidation even at high temperatures. It is characterized by high mechanical strength and suitable for furnace temperatures up to 1200°c (2192°f). Wire temperature 500 o c. Due to its ductibility and strength at high temperature, nichrome 80 is especially suitable for applications in the electrical appliance industry. Materials for electric heating depend upon an inherent resis tance to the flow of electricity to generate heat. That's slightly more than a fourth of 400°f. It is widely used in the application of. Typical applications for nikrothal ® 80/20 cb are as wire in mesh belts. Oxidized wires of these alloys display better insulation properties. (0.68 = 26v / 38ω). Compare the properties and specifications of different gauges and diameters of alloy 650 wire. Nic80 is an alloy of 80% nickel and 20% chromium and represents the highest standard in materials for use. Web nicr 80:20 is suitable for heating elements used for temperatures upto 1200°c. Wire temperature 500 o c. It is widely used in the application of industrial furnaces and even provides the means to. Oxidized wires of these alloys display better insulation properties. It has good ductility after use and excellent weldability. It has a high melting point and fantastic resistance to high temperature oxidation. Web nichrome 80 is an alloy consisting of 80% nickel, and 20% chromium. Our nichrome wire has an appreciable temperature rating of 1177°c (2150°f), is corrosion resistant, and resists oxidation even at high temperatures. Web introduction to resistance heating alloys. Copper wire does not get appreciably hot. Web elements, cartridge elements, quartz tube heaters, etc. Web omegatm nic80 wire is a resistance heating wire comprised of 80% nickel and 20% chromium. Web introduction to resistance heating alloys. Typical applications for nikrothal ® 80/20 cb are as wire in mesh belts. Withstands high temperatures up to 2100°f. It has good ductility after use and excellent weldability. Wire temperature 500 o c. Compare the properties and specifications of different gauges and diameters of alloy 650 wire. It has highly corrosion resistance and lower coefficient of resistance than other heater element alloys. Web niwire industries is a manufacturer of nickel alloys, duplex, super duplex steels, 6% moly and other. Lead time (if not in stock): Nichrome wire chart shows the resistivity and ampere rating of nicr a and nicr c coils. Nic80 is an alloy of 80% nickel and 20% chromium and represents the highest standard in materials for use in elevated. Wire temperature 500 o c. + add to project list. The nichrome coil resistance and the current rating necessary to produce a given temperature specified in nichrome wire data sheet varies for different type of alloy used. It has a high melting point and fantastic resistance to high temperature oxidation. It has highly corrosion resistance and lower coefficient of resistance than other heater element alloys. (0.68 = 26v / 38ω). Web with your 38ω piece of wire (straightened out, not coiled) to 400°f, that is ~26v ( not including resistance changes ). Due to its ductibility and strength at high temperature, nichrome 80 is especially suitable for applications in the electrical appliance industry. Withstands high temperatures up to 2100°f. Compare the properties and specifications of different gauges and diameters of alloy 650 wire. The alloy is characterized by high resistivity, good oxidation resistance and very good form stability. Due to its ductibility and strength at high temperature, nichrome 80 is especially suitable for applications in the electrical appliance industry. Copper wire does not get appreciably hot when carrying electricity because it has good electrical conductivity.

26 AWG 100 ft Nichrome 80 Resistance Wire TEMCo Industrial

solid state physics What is the bump in the resistivity vs

Nichrome Resistance Strip

Nichrome Wire Resistance Chart

Informational Charts For Nichrome & Resistance Wires

Nichrome 80 100 ft Spool Nichrome 80

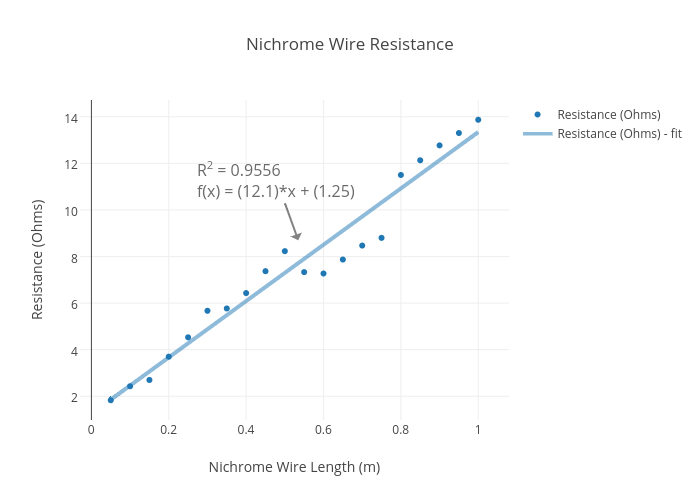

Nichrome Wire Resistance scatter chart made by Kylebali101 plotly

N (N V, Cl A) C 0.99

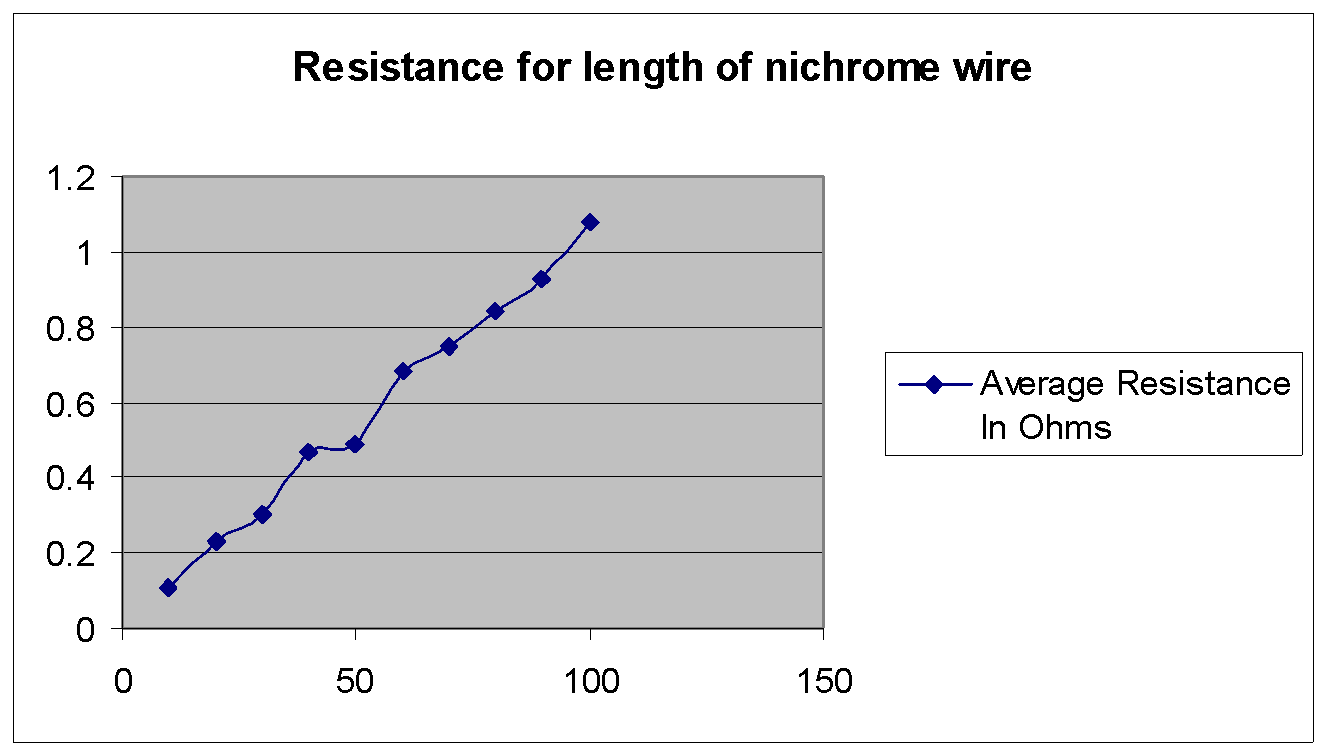

Investigate the effects of resistance on a nichrome wire GCSE Science

Nichrome Wire Resistance Chart

Web Nicr 80:20 Is Suitable For Heating Elements Used For Temperatures Upto 1200°C.

Used To Make Straight Or Helical Coil Resistance Heaters.

Web Elements, Cartridge Elements, Quartz Tube Heaters, Etc.

Materials For Electric Heating Depend Upon An Inherent Resis Tance To The Flow Of Electricity To Generate Heat.

Related Post: