Motor Pulley Size Chart

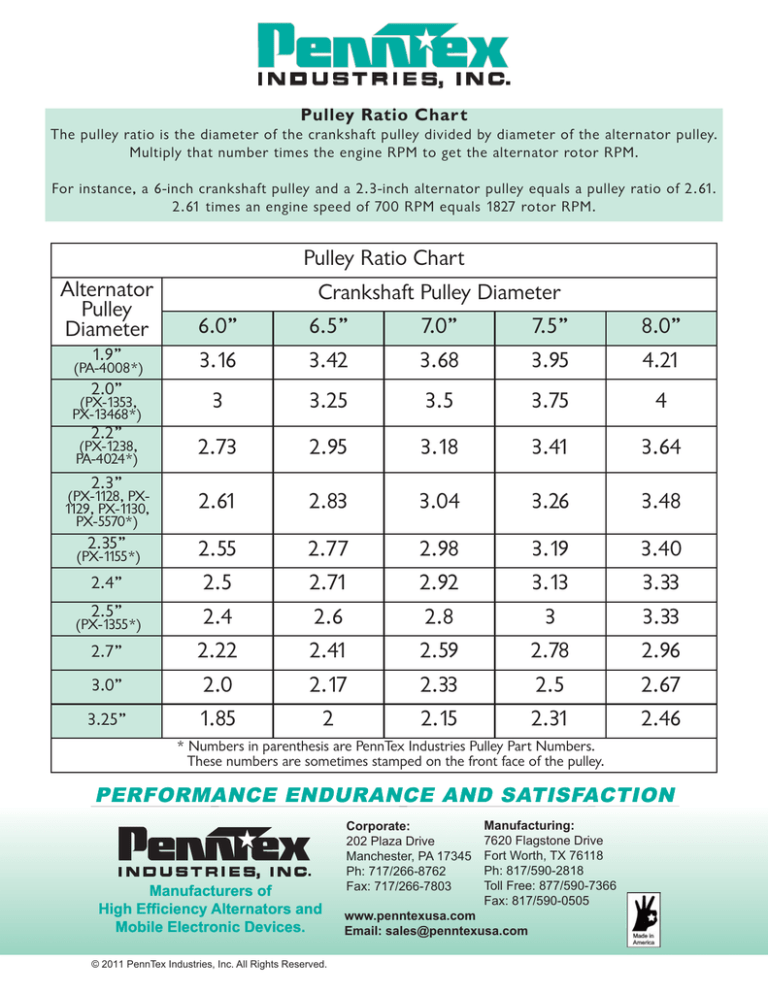

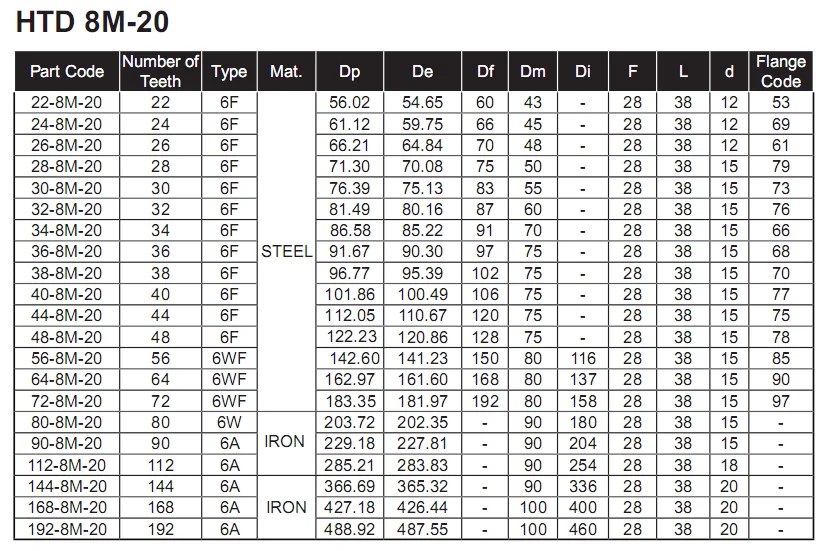

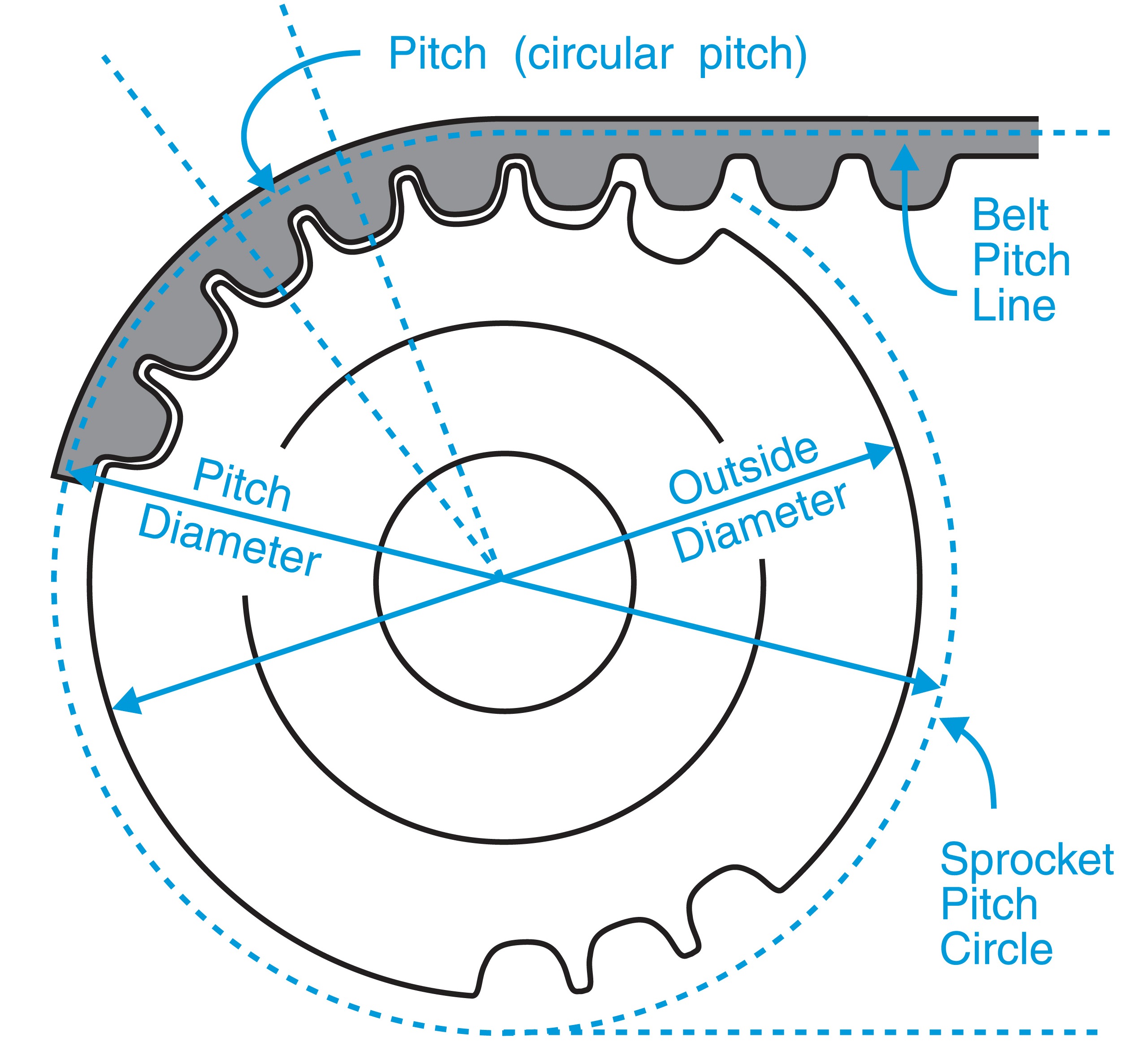

Motor Pulley Size Chart - V and flat belt design and engineering data. Web learn how to measure your pulley or sheave. The article guides electrical engineers on electric motor sizing and selection to satisfy their power system requirements. “u” = distance between the tensile cord and the bottom of the timing belt tooth. Web november 15, 2022 by simon mugo. It’s very important to make sure you have the correct pulley sizing of motors and engines relative to the pump. It is possible to use a or b belts in fractional horsepower applications, but it is not necessarily recommended for the reverse. To calculate machine rpm we need the motor rpm and both pulley sizes. Web ratio = crankshaft pulley diameter / alternator pulley diameter. You can then determine the rotor speed using your known ratio: The width of the belt used. Web the outside length is 31, the inside length is 29. Belts with “l” in the name are for fractional horsepower only. “u” = distance between the tensile cord and the bottom of the timing belt tooth. Designers need high quality components in order to maintain performance and contain operating costs. Designers need high quality components in order to maintain performance and contain operating costs. Web pump outflow rate may be measured in liters or gallons per minute, for example. Click on the images below to enlarge. The width of the belt used. Web table of contents. The article guides electrical engineers on electric motor sizing and selection to satisfy their power system requirements. To calculate machine rpm we need the motor rpm and both pulley sizes. Web learn how to measure your pulley or sheave. Pulley system some pulley formulas calculating pulley rpm and speed: Web a rpm pulley calculator to determine the motor or drive. Different brands, as well as different pulley types, have various ways they may display these numbers. 2 finding the size using the pulleys. Pulley system some pulley formulas calculating pulley rpm and speed: 1 in = 25.4 mm; Match your pulleys to your belts for extended service life. To find the rpm (n₂) of the driven pulley, measure its diameter (d₂) and apply the values alongside the driving pulley’s rpm (n₁) in the formula. To calculate machine rpm we need the motor rpm and both pulley sizes. Web a rpm pulley calculator to determine the motor or drive speeds or size of a pulleys and gears. Based on. The width of the belt used. Web the outside length is 31, the inside length is 29. Allowable shaft ø (mm) bearing center type; 1 in = 25.4 mm; Click on the images below to enlarge. Based on calculations, select the pulley sizes that align with the desired speed ratio and load requirements. Web 1 using an existing belt. Web the electric motor is a machine capable of converting electrical energy into mechanical energy. Allowable shaft ø (mm) bearing center type; You can then determine the rotor speed using your known ratio: Web the distance from the timing belt tooth bottom to the tensile cord (pitch line) will determine the outside diameter (o.d.) of the timing belt pulley for any timing belt pitch/timing belt tooth profile. Terre products measuring guide explains pulley specs and dimensions. Measuring a v belt or flat pulley is easy. Measure the diameter (d₁) of the driving pulley.. To calculate machine rpm we need the motor rpm and both pulley sizes. Web ratio = crankshaft pulley diameter / alternator pulley diameter. Measure the diameter (d₁) of the driving pulley. Web updated march 2, 2024. Match your pulleys to your belts for extended service life. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). Standard pulley dimensions belt width (mm) face width (mm) bearing centers (mm) max. D1 n1= d2n2 (1) where. Web learn how to measure your pulley or sheave. 2.1 x 870 = 1827 rotor rpm) You can then determine the rotor speed using your known ratio: Click on the images below to enlarge. This pulley calculator analyzes a system of two pulleys joined by a conveyor belt (also called a belt drive). Web determine which pulley acts as the driver (higher rpm) and which is driven (lower rpm). 2 finding the size using the pulleys. Allowable shaft ø (mm) bearing center type; 2.1 x 870 = 1827 rotor rpm) 1 in = 25.4 mm; Match your pulleys to your belts for extended service life. Web a rpm pulley calculator to determine the motor or drive speeds or size of a pulleys and gears. Cost efficiency is critical in engineering, including power transmission projects. To calculate machine rpm we need the motor rpm and both pulley sizes. Web the distance from the timing belt tooth bottom to the tensile cord (pitch line) will determine the outside diameter (o.d.) of the timing belt pulley for any timing belt pitch/timing belt tooth profile. Web 1 using an existing belt. Belts with “l” in the name are for fractional horsepower only. The speed pulley calculator is a sophisticated tool designed to calculate the output speed of a driven pulley based on the input speed of a driving pulley and the diameters of both pulleys.

Pulley Ratio Chart PennTex Industries, Inc.

Motor Pulley Size Chart

Technical Blower pulleys size The H.A.M.B.

Tabel Ukuran Pulley

Electric Motor Pulley Size Chart

How to Calculate Size of Pulley for Pump and Motor YouTube

990360 Single Groove Electric Motor Belt Wheel Pulley Aluminium Aimtools

Motor Pulley Sizing

5mm timing belt pulley honest service

Diagrams and Definitions of Pulleys

Terre Products Measuring Guide Explains Pulley Specs And Dimensions.

“U” = Distance Between The Tensile Cord And The Bottom Of The Timing Belt Tooth.

Use The Speed Ratio And Motor Rpm To Compute The Diameters Of The Driver And Driven Pulleys.

Web Motor And Equipment Speed For Pulleys With Different Diameters Are Indicated In The Charts Below:

Related Post: