Minitab Xbar R Chart

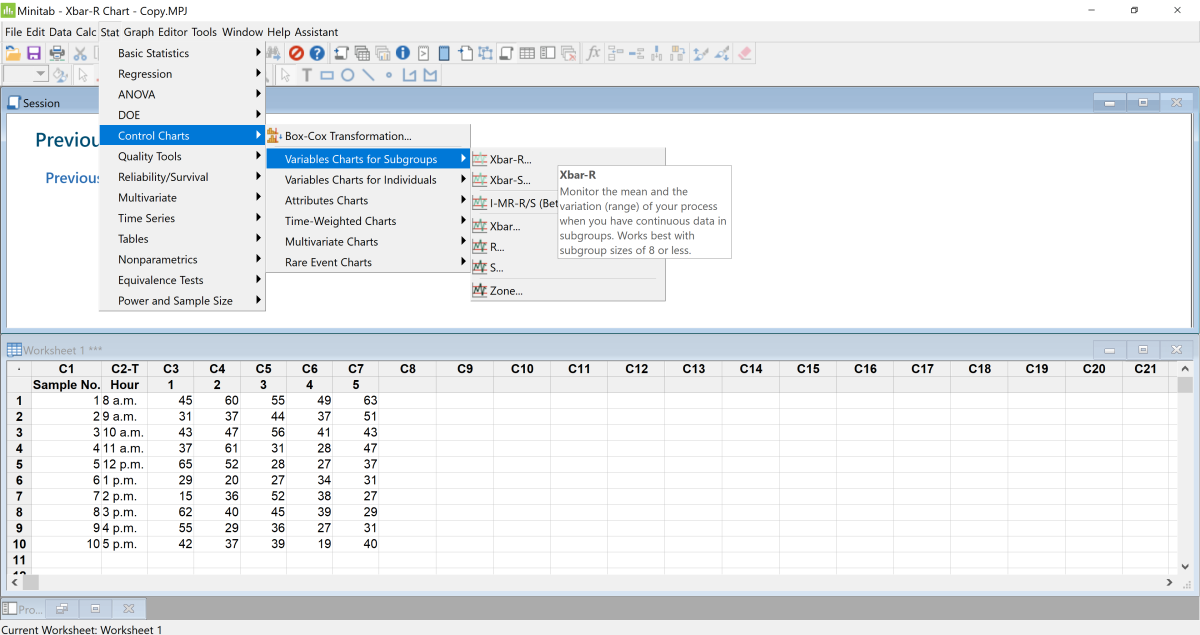

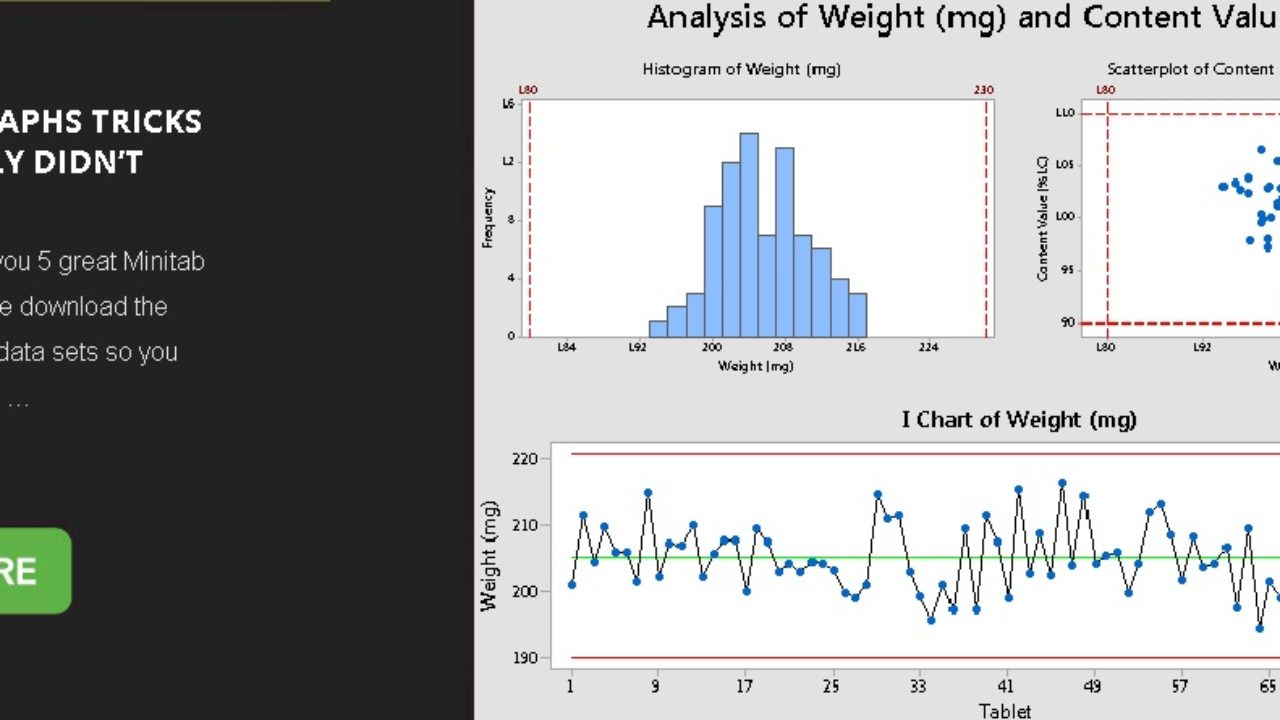

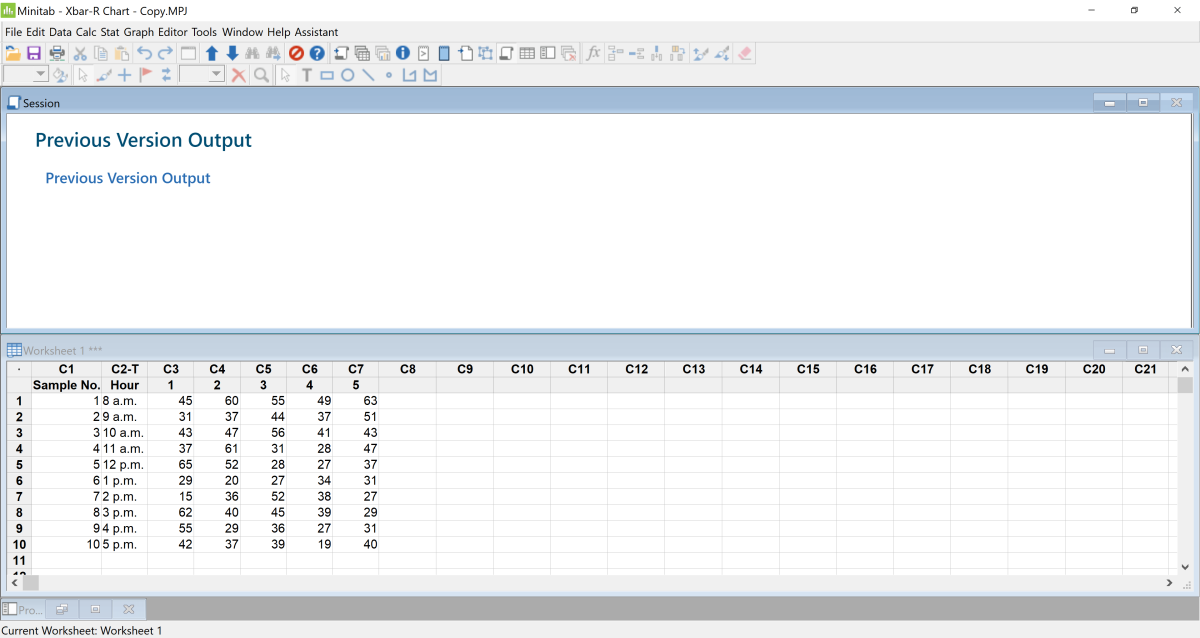

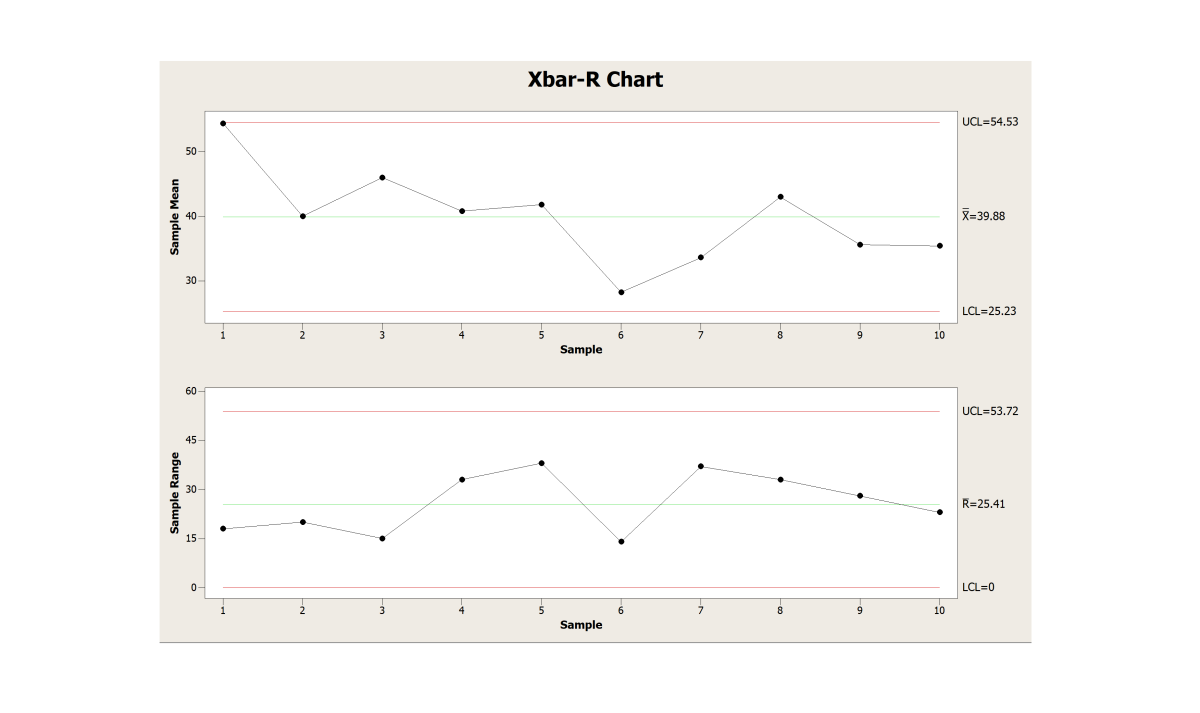

Minitab Xbar R Chart - For more information on control charts, see understanding statistical process control by donald j. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Identify which points failed each test. Start a new stage with each new value from a column. Choose xbar options, then click the parameters tab. Screenshots are provided for each step, making it easy for beginners to follow along. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. Select the option that best describes your data. The r chart plots the difference between the highest and lowest values within a subgroup as a. If you have attribute data, you need to determine if you're looking at proportions or counts. The lesson describes how to create this control chart in both microsoft excel and using minitab. This lesson explains how the data is recorded and interpreted on the chart. Web use xbar chart to monitor the mean of your process when you have continuous data in subgroups. Hello, i have been trying to calculate control limits (xbar r charts) for. For more information on control charts, see understanding statistical process control by donald j. When discussing spc, this is always the example. Each plotted point, , represents the mean of the observations for subgroup,. In define stages (historical groups) with this variable, enter the column that identifies the stages. Using the center line and the control limits from the stable. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. Enter the mean and standard deviation. Using the center line and the control limits from the stable process (using either of the methods described above), the chart now reveals the new process is out of control. This. Date | x1 | x2 | x3 | x4 | x5 | variable type. Go to stat > control charts > variables for subgroups > xbar & r: Examine the xbar chart to determine whether the process mean is in control. We use the means chart to estimate the population mean of a process and the range chart to observe. Hello, i have been trying to calculate control limits (xbar r charts) for 100 variables using minitab. For more information on control charts, see understanding statistical process control by donald j. Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. Web the xbar r chart is. This lesson explains how the data is recorded and interpreted on the chart. Each plotted point, , represents the mean of the observations for subgroup,. Choose observations for a subgroup are in one row of columns, then click x1, x2, x3, x4, x5 in the box. We use the means chart to estimate the population mean of a process and. Select the method or formula of your choice. Screenshots are provided for each step, making it easy for beginners to follow along. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in a process. This lesson explains how the data is recorded and interpreted on the chart. Select the option that. Using the center line and the control limits from the stable process (using either of the methods described above), the chart now reveals the new process is out of control. For more information on control charts, see understanding statistical process control by donald j. To ensure that your results are valid, consider the following guidelines when you collect data, perform. Examine the xbar chart to determine whether the process mean is in control. Once mastered, it provides data to leaders on changes they should make as well as measuring the success of changes put into place. We use the means chart to estimate the population mean of a process and the range chart to observe how the population variation changes.. In define stages (historical groups) with this variable, enter the column that identifies the stages. Web use xbar chart to monitor the mean of your process when you have continuous data in subgroups. Date | x1 | x2 | x3 | x4 | x5 | variable type. If you have attribute data, you need to determine if you're looking at. In define stages (historical groups) with this variable, enter the column that identifies the stages. Web the xbar r chart is a control chart for continuous data with a constant subgroup size between two and ten. Select the option that best describes your data. Screenshots are provided for each step, making it easy for beginners to follow along. Start a new stage with each new value from a column. Web choose stat > control charts > variables charts for subgroups > xbar. Enter the mean and standard deviation. Choose stat > control charts > variables charts for subgroups > xbar. Choose xbar options, then click the parameters tab. All of this data is stored in excel columns in this way: The r chart plots the difference between the highest and lowest values within a subgroup as a. Web this historical control chart shows three stages of a process, which represent before, during, and after the implementation of a new procedure. Date | x1 | x2 | x3 | x4 | x5 | variable type. The lesson describes how to create this control chart in both microsoft excel and using minitab. Examine the r chart to determine whether the process variation is in control. We use the means chart to estimate the population mean of a process and the range chart to observe how the population variation changes.

How to Create an XbarR Chart in Minitab 18 ToughNickel

MinitabDataAnalysisXbarRChart CSense Management Solutions

How To Make X Bar R Chart In Minitab Chart Examples

X Bar And R Chart Minitab Chart Examples

Introduction to the X Bar R Control Chart using Minitab Version 20

Minitab による XbarR管理図

How to Create an XbarR Chart in Minitab 18 ToughNickel 德赢Vwin888

Control chart X bar R chart with evalutation Minitab YouTube

How to Create an XbarR Chart in Minitab 18 ToughNickel

How to Create an XbarR Chart in Minitab 18 ToughNickel

The Engineer Looks At The R Chart First Because, If The R Chart Shows That The Process Variation Is Not In Control, Then The Control Limits On The Xbar Chart Are Inaccurate.

Don't Forget To Subscribe And Share.

The Xbar Chart Plots The Average Of A Subgroup As A Data Point.

Identify Which Points Failed Each Test.

Related Post: