Mig Settings Chart

Mig Settings Chart - Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Got your welding helmet ready? What shielding gas to use and how to attach it to your machine. Web learn how to set the right amps for mig welding different types and thicknesses of metal with this chart. Sheet metal is a thin and lightweight material used in many products, including car bodies, appliances, and aircraft. Web weld setting calculator app. Web the heat and rays of the arc can react with vapors to form highly toxic and irritating gases. Find out how voltage, wire speed, and gas flow affect the weld quality and appearance. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Individual settings most mig welders have. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint. Got your welding helmet ready? Web mig welding sheet metal settings with charts. However, welding sheet metal can. Are you looking for a guide for mig welding amperage? These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. However, welding sheet metal can be challenging due to its low thickness and high heat conductivity. Web how to set up your mig welder. When mig welding aluminum, the desired mode is spray transfer. Find out other factors that influence mig welding settings, such as wire, gas, and transfer types. There are many mig setting charts available from manufacturers that all vary. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Find out other factors that influence mig welding settings, such as wire, gas, and transfer types. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Sheet metal is a thin and lightweight material used in many products,. When mig welding aluminum, the desired mode is spray transfer. The droplets crossing the arc are smaller in diameter than the electrode. Individual settings most mig welders have. Got your welding helmet ready? Web what material are you welding? This is why mig welding is considered one of the easiest types of welding to learn and a great place to start for beginners. Optimal settings ensure proper heat and wire speed for smooth, strong welds. Web the settings of your mig welder, from the amperage to the thickness of your material, make all the difference in the end result. Optimal settings ensure proper heat and wire speed for smooth, strong welds. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and deposits the workpiece metal in the weld joint. The droplets crossing the arc are. Incorrect parameters can lead to poor weld quality, lack of penetration, concave welds, undercut, and other weld deformities. Download the app version of the weld setting calculator for easy reference! Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding. February 20, 2023 by sandeep kumar. Find out other factors that influence mig welding settings, such as wire, gas, and transfer types. Web what material are you welding? Web how to set up your mig welder. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Web learn how to set the right amps for mig welding different types and thicknesses of metal with this chart. Optimal settings ensure proper heat and wire speed for smooth, strong welds. Web learn how to set up your mig welder for different materials, thicknesses, and shielding gases. However, welding sheet metal can be challenging due to its low thickness. Web learn how to set up your mig welder for different materials, thicknesses, and shielding gases. This process is a very smooth transfer of molten metal droplets from the end of the electrode to the molten pool. February 20, 2023 by sandeep kumar. Web mig welding sheet metal settings with charts. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Web the heat and rays of the arc can react with vapors to form highly toxic and irritating gases. Download the app version of the weld setting calculator for easy reference! You may need to dial them in, depending on your setup. When mig welding aluminum, the desired mode is spray transfer. This is why mig welding is considered one of the easiest types of welding to learn and a great place to start for beginners. Web weld setting calculator app. Find out other factors that influence mig welding settings, such as wire, gas, and transfer types. Web follow this comprehensive guide with a chart to learn how to set your mig welder accurately and effectively. Incorrect parameters can lead to poor weld quality, lack of penetration, concave welds, undercut, and other weld deformities. What shielding gas to use and how to attach it to your machine. Got your welding helmet ready?

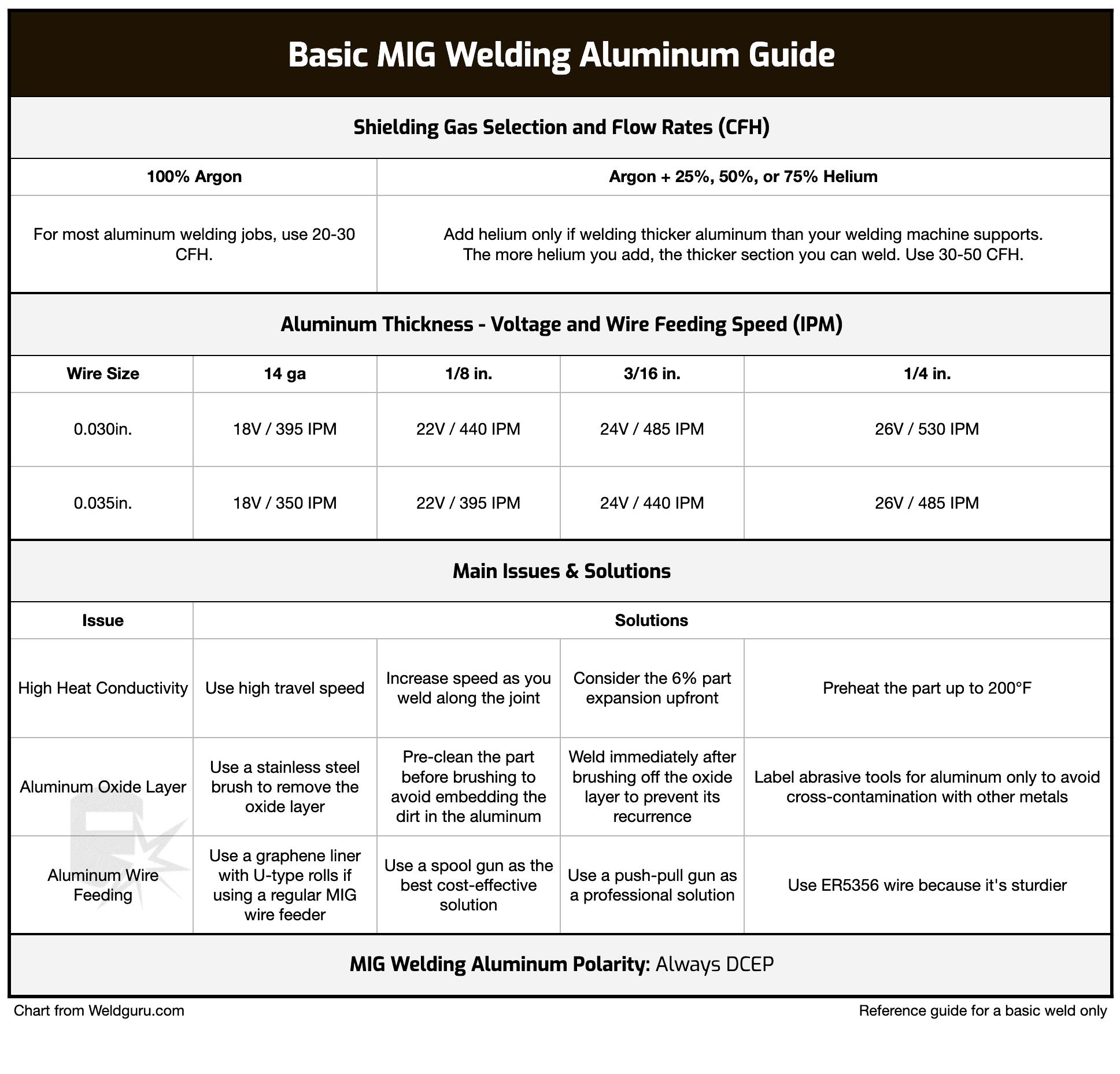

How To MIG Weld Aluminum Beginners Guide (with Chart)

MIG Welding Gas Pressure Settings (with Charts)

MIG Welding Aluminum Electrodes, Gasses, Welder Setting & Equipment

Basics of MIG Welding 17 Steps (with Pictures) Instructables

Important MIG Welder Settings You Need to Know (with Chart)

How To MIG Weld Aluminum Beginners Guide (with Chart)

Mig Welding Settings Chart Metric Pdf

Mig Welder Settings Chart

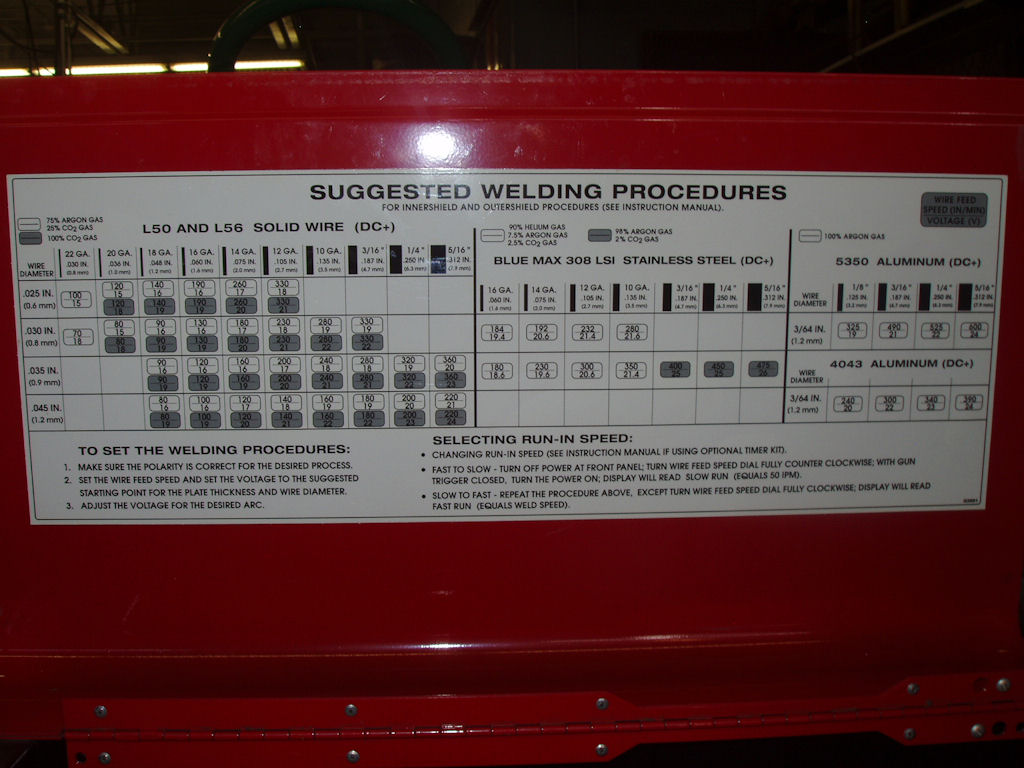

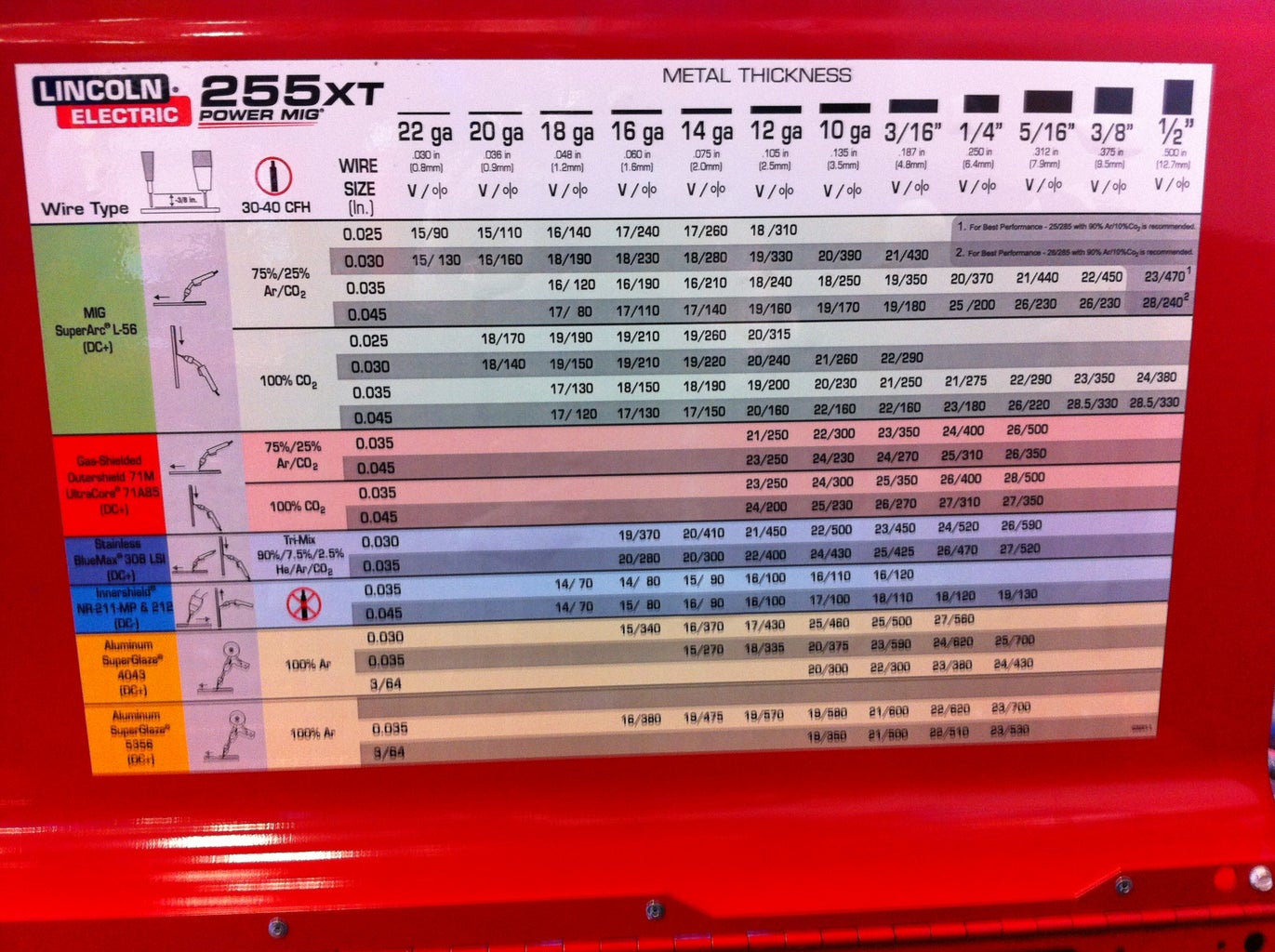

Lincoln Mig Welder Settings Chart

242 MIG Settings Chart PDF Metalworking Metals

Individual Settings Most Mig Welders Have.

There Are Many Mig Setting Charts Available From Manufacturers That All Vary.

Web What Material Are You Welding?

Utilize The Guides And Tips Listed Above To Ensure You Get Quality Results Every Time.

Related Post: