Metal Thickness Stick Welding Amperage Chart

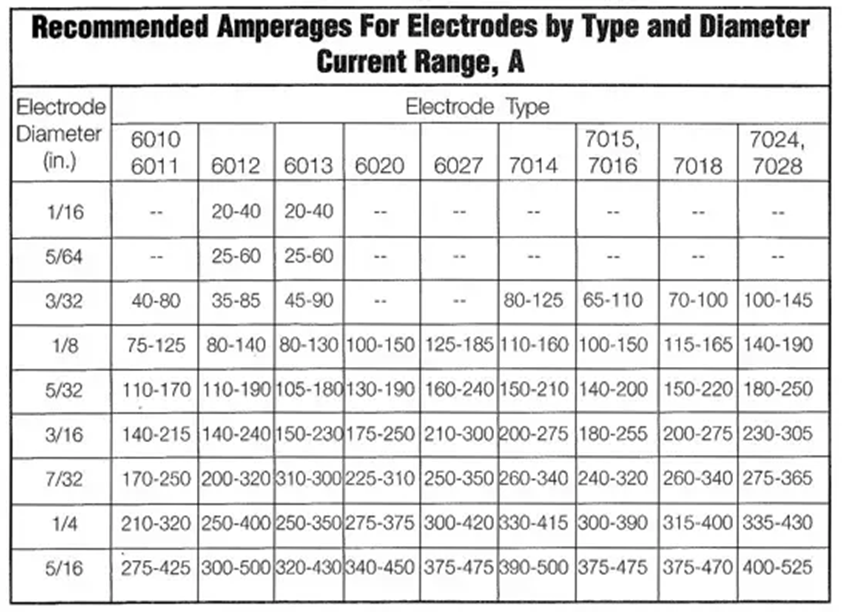

Metal Thickness Stick Welding Amperage Chart - Your mig welding wire size will determine the amperage setting used. Web our powerful calculator let's you easily determine which stick electrode you need. Disconnect input power or stop engine before installing or servicing this equipment. No features could limit the heat output like in mig welding or tig welding processes, but higher penetration handles thick metal very well. A = p / v. Browse suggested weld parameter settings for stick welding. In most situations, use of a dc, constant voltage wire welder is recommended. Web what material are you welding? And, do not work alone! Arc force (dig) for vertical welding. No features could limit the heat output like in mig welding or tig welding processes, but higher penetration handles thick metal very well. Tig welding amperage and voltage. Web our powerful calculator let's you easily determine which stick electrode you need. A is the welding machine amperage (amps) p is the power consumption/load (kw) v is the voltage (volts) what. And, do not work alone! If the flow rate is off, even by a small amount, it can lead to various welding defects and faulty joints. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Web stick welding rod sizes. The number represents the diameter of the rod, while the letter indicates the type These charts provide information on recommended rod sizes based on material thickness and welding amperage. If the flow rate is off, even by a small amount, it can lead to various welding defects and faulty joints. Welding is a precise craft that demands attention to detail,. Web stick welding rod sizes are designated by a system of numbers and letters. Web what material are you welding? The gas flow rate is crucial to ensure the joint's durability, integrity, and quality. Before tackling any mig welding application, look at the charts and tips below. The adjustments to stick welding amperage to compensate for steel material thickness are. Before tackling any mig welding application, look at the charts and tips below. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. What is the best rod for vertical welding? If the flow rate is off, even. The number represents the diameter of the rod, while the letter indicates the type Web choose the right amperage for stick welding by considering material thickness and electrode diameter. Web table of contents. Use the charts provided to help you choose the best setup for each application. If the flow rate is off, even by a small amount, it can. Welding is a precise craft that demands attention to detail, and one crucial aspect of achieving quality welds is determining the correct amperage for your stick welder. Web january 16, 2023 by sandeep kumar. Should you stick weld up or down? No features could limit the heat output like in mig welding or tig welding processes, but higher penetration handles. Web stick welding rod sizes are designated by a system of numbers and letters. Plus a chart with rod size and amperage per metal thickness in inches and mm. The number represents the diameter of the rod, while the letter indicates the type Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top. Tig welding amperage and voltage. In most situations, use of a dc, constant voltage wire welder is recommended. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Always follow electrode manufacturer’s guidelines. Consulting a reputable manufacturer’s website or a welding handbook can help you find a. Meanwhile, the smaller the rod is, it will be ideal for lower metal thickness and require less amperage. These charts provide information on recommended rod sizes based on material thickness and welding amperage. Vertical stick welding amperage per metal thickness in inches and mm. If the flow rate is off, even by a small amount, it can lead to various. Web stick welding rod sizes vary from 1/16 inch, or 1.4 mm, up to 1/4 or 6.4 mm and over. Your mig welding wire size will determine the amperage setting used. Before tackling any mig welding application, look at the charts and tips below. Tig welding amperage and voltage. Welding is a precise craft that demands attention to detail, and one crucial aspect of achieving quality welds is determining the correct amperage for your stick welder. A = p / v. Disconnect input power or stop engine before installing or servicing this equipment. Web our powerful calculator let's you easily determine which stick electrode you need. The thicker the rod is, the more suitable it is for thicker metal, but it will require a higher amperage. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. A guide for stick welders. Arc force (dig) for vertical welding. Should you stick weld up or down? A low carbon content means it is similar to iron, soft, and easily formed. Web stick welding amperage for different steel thicknesses. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode.

Stick Welding Amperage Chart Welding Information

ضبط الامبير للحام القواعد الذهبية فى اللحام القاعدة الرابعةWelding

7018 1/8 Welding Rod Amperage Chart

How to Prevent Welding Rod Sticking to The Metal Welding Tribe

Stick Welding Amp Chart

Stick Amps Vs Rod size Vs metal thickness Welding rod chart, Welding

What are a reasonable rods to use ? Welding Site

Tig Welding Amperage Chart

Metal Thickness Stick Welding Amperage Chart

Metal Thickness Stick Welding Amperage Chart

Web What Material Are You Welding?

These Charts Provide Information On Recommended Rod Sizes Based On Material Thickness And Welding Amperage.

Web There Are Various Criteria To Consider When Setting Your Mig Weld Controls, Including Materials, Metal Thickness, Shielding Gas, Electrode Wires, And Amperage.

Web Table Of Contents.

Related Post: