Melting Point Of Solder Chart

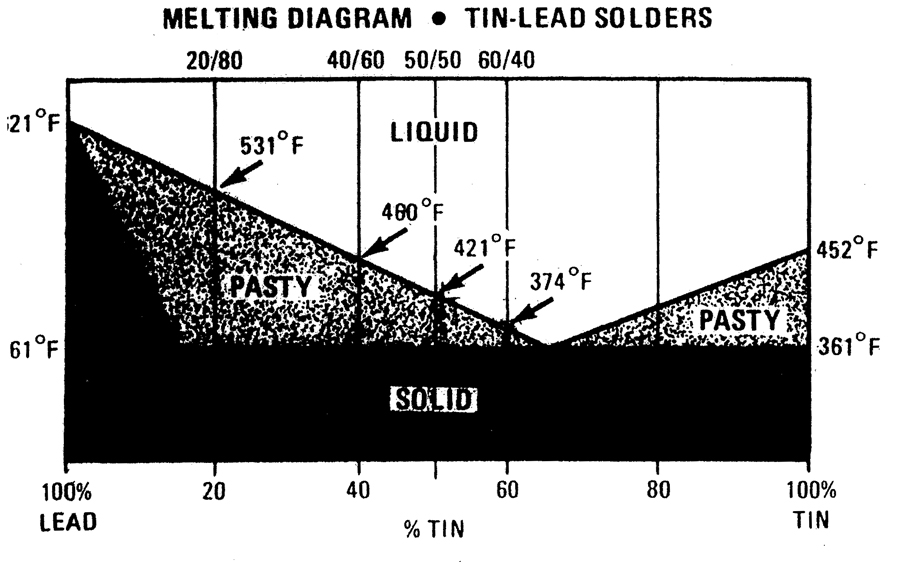

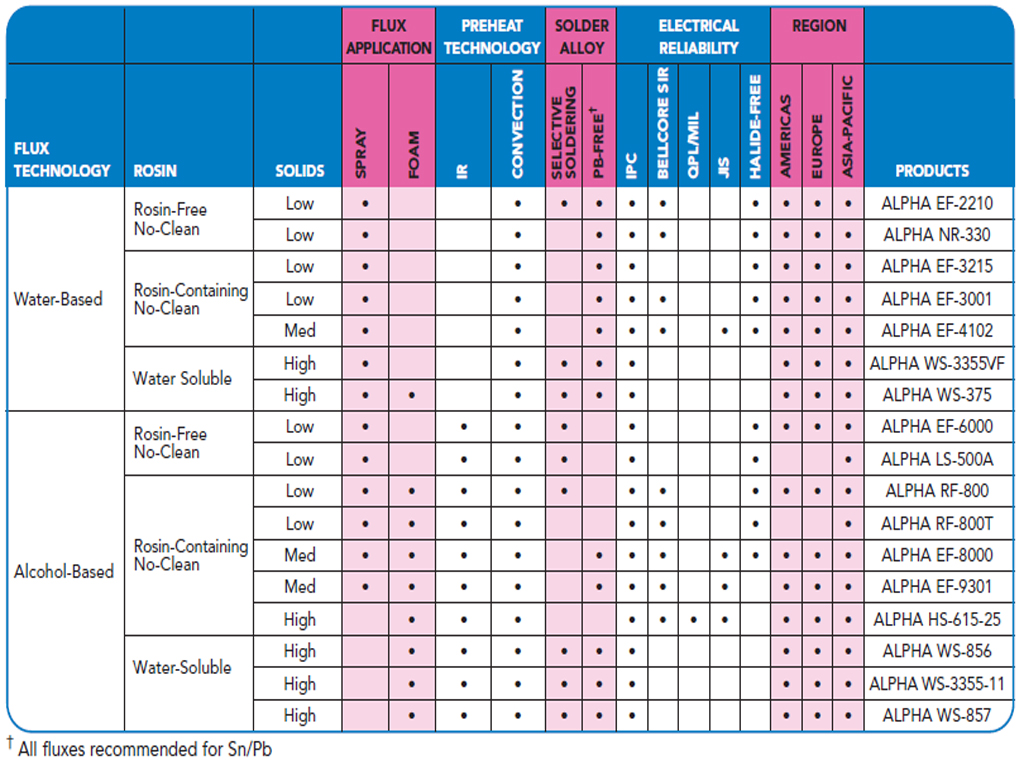

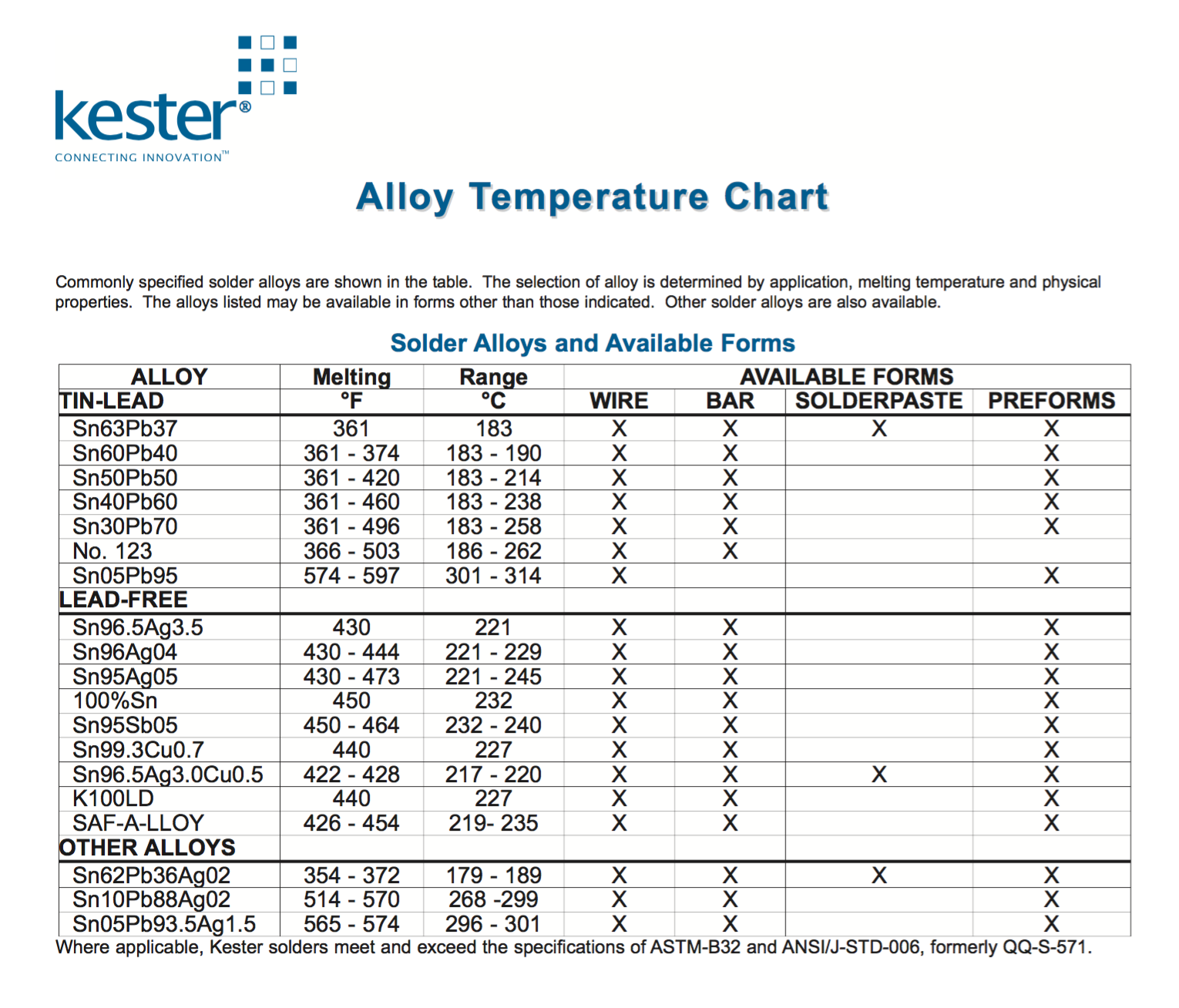

Melting Point Of Solder Chart - The selection of alloy is determined by application, melting temperature and physical properties. Solder alloy compositions (% weight) metal composition. The melting point of 60/40 solder is. Also, you can determine the quality of a solder through its high conductivity and low flux content. This specifies a good quality solder metal. Solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning into liquid at 361.4°f (183°c), then completely turn into liquid at 375.8°f (191°c). Web it typically consists of a mixture of tin and lead and has a low melting point, making it easy to work with. This tin can be 60% while the lead is 40%. This temperature chart shows the different solders that are available and their melting temperatures. The selection of any particular solder alloy for an application is based on the melting point of that solder. Most printed circuit boards and electronic components are soldered using standard melting point alloys. This temperature chart shows the different solders that are available and their melting temperatures. Commonly specified solder alloys are shown in the table. This tin can be 60% while the lead is 40%. Solder comprises an alloy of lead and tin. To avoid conspicuous solder lines, use the highest temperature solder feasible. Commonly specified solder alloys are shown in the table. Web melting temperatures of solder are determined by the zinc content: The melting point of solder is the temperature at which the solder changes its state from solid to liquid. A typical solder such as 60/40, with 60 % tin,. This specifies a good quality solder metal. Solder comprises an alloy of lead and tin. The eutectic composition, consisting of 63% tin (sn) and 37% lead (pb), has a melting point of approximately 183°c (361°f). Hard solder, also known as silver solder or silver brazing, is used for joining metals. The typical melting point of the general solder is in. Commonly specified solder alloys are shown in the table. Solder alloy compositions (% weight) metal composition. The eutectic composition, consisting of 63% tin (sn) and 37% lead (pb), has a melting point of approximately 183°c (361°f). Solder with a composition of 60% tin and 40% lead has a varying melting range but will begin turning into liquid at 361.4°f (183°c),. Web impact of temperature on solder melting point. The selection of alloy is determined by application, melting temperature and physical properties. Other solder alloys are also available. The selection of any particular solder alloy for an application is based on the melting point of that solder. A typical solder such as 60/40, with 60 % tin, and 40 % lead,. Hard solder, also known as silver solder or silver brazing, is used for joining metals. See my handy tip for holding solder while manually soldering. Also, you can determine the quality of a solder through its high conductivity and low flux content. Web melting temperatures of solder are determined by the zinc content: Commonly specified solder alloys are shown in. Web solders comprise dozens of alloy compositions, with melting points as low as 90° to as high as 400°c. Hard solder, also known as silver solder or silver brazing, is used for joining metals. The selection of alloy is determined by application, melting temperature and physical properties. So, your soldering iron temperature should be higher by 68 to 86 degrees. The selection of alloy is determined by application, melting temperature and physical properties. The selection of any particular solder alloy for an application is based on the melting point of that solder. Web the right melting point of solder is about 250 degree celsius. Web the alloy temperature chart lists the alloys that are available from kester. The presence of. Web here is a table that shows the different alloy compositions of solder and their melting point ranges that are common in pcb manufacturing. Commonly specified solder alloys are shown in the table. The selection of alloy is determined by application, melting temperature and physical properties. Web melting temperatures of solder are determined by the zinc content: The alloys listed. Different ratios of tin and lead result in varying melting points. The alloys listed may be available in forms other than those indicated. The selection of alloy is determined by application, melting temperature and physical properties. This tin can be 60% while the lead is 40%. See my handy tip for holding solder while manually soldering. Commonly specified solder alloys are shown in the table. The higher the zinc content, the lower the melting temperature. The selection of alloy is determined by application, melting temperature and physical properties. So, your soldering iron temperature should be higher by 68 to 86 degrees fahrenheit (20 to 30 degrees celsius). Web explore a curated collection of tables and charts that provide melting point data for different materials, including metals, polymers, ceramics, fluids, and more. Also, you can determine the quality of a solder through its high conductivity and low flux content. Web solders comprise dozens of alloy compositions, with melting points as low as 90° to as high as 400°c. This specifies a good quality solder metal. Web the alloy temperature chart lists the alloys that are available from kester. Different ratios of tin and lead result in varying melting points. To avoid conspicuous solder lines, use the highest temperature solder feasible. The selection of alloy is determined by application, melting temperature and physical properties. The presence of lead in these alloys lowers the melting point, making them easier to work with. The melting point of 60/40 solder is. The alloys listed may be available in forms other than those indicated. Web the melting temperature for alloy solder, which is the most common type of solder, is around 360 to 370 degrees fahrenheit (or 180 to 190 degrees celsius, if you’re accustomed to using the metric system).

Eutectic vs Leadfree solder Iron Tip temperature Japanpeuf

Electrical and Thermal conductivity of Metals r/Wallstreetsilver

Patent EP0977900A4 Leadfree solder Google Patents

Soldering Iron and Controllers Lawrence Ribbecke Studios

Solder Melting Point Chart

Basic Soldering Guide How to Solder Electronic Components to PCB

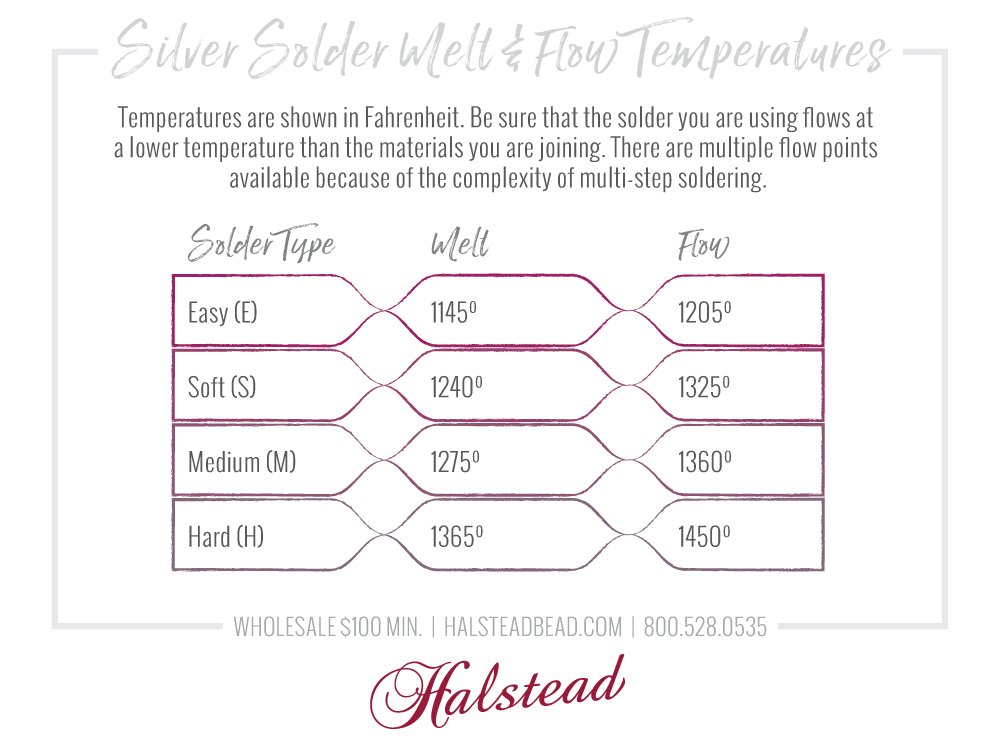

Solders, Torches & Fuels Used in a Jewelry Studio Halstead

kester solder melting points

Silver Solder Melting Temperature Chart

Solder and Soldering Guide Farnell element14

Web Here Is A Table That Shows The Different Alloy Compositions Of Solder And Their Melting Point Ranges That Are Common In Pcb Manufacturing.

Web It Typically Consists Of A Mixture Of Tin And Lead And Has A Low Melting Point, Making It Easy To Work With.

Most Printed Circuit Boards And Electronic Components Are Soldered Using Standard Melting Point Alloys.

Solder Comprises An Alloy Of Lead And Tin.

Related Post: