Lincoln Welding Rod Chart

Lincoln Welding Rod Chart - Smaw (1) any e70x8 electrode may be. In this article, i’ll cover the most. Automotive & transportation high speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.; Web lincoln electric consumables for each application. Mig wires and tig rods filler metals made from the. Weld with the electrode end lightly dragging on the work to force the. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. Web welding rod sizes sizes & material thickness chart (mild steel) contents. Welding rod sizes and base metal thickness chart. Used for welding of cast irons to other cast irons as well as for joining cast irons to mild steels and stainless steels. Smaw (1) any e70x8 electrode may be. Web here is a chart showing the ideal settings for working with a lincoln stick welder. Other charts are available from cable manufacturers and welding reference books. Web lincoln electric consumables for each application. Web the lincoln electric company 22801 st. Web welding rod sizes sizes & material thickness chart (mild steel) contents. Welding rod sizes and base metal thickness chart. Web lincoln electric consumables for each application. Web stick electrodes for mild and low alloy steel welding. Other charts are available from cable manufacturers and welding reference books. Please be sure to use the notes as an aid in selecting lincoln electric consumables. Automotive & transportation high speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.; Web the lincoln electric company 22801 st. Mig wires and tig rods filler metals made from the. Automotive & transportation high speed, low spatter and controlled heat. Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean. Web the lincoln electric company 22801 st. Automotive & transportation high speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.; Web lincoln electric consumables for each application. Web see our chart and guide on. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Welding rod sizes and base metal thickness chart. In this article, i’ll cover the most. Automotive & transportation high speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.; Other charts. In this article, i’ll cover the most. Automotive & transportation high speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.; Web lincoln electric consumables for each application. Other charts are available from cable manufacturers and welding reference books. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Web 0.5 1 2.5 5 10 15 20 30 40 80 125 175 225 275 350 450 60 100 150 200 250 300 400 500 10 11 12 13 910 11 12 13 10 11. Web 7 rows diffusible hydrogen. Web for vertical up and vertical down pipe welding technique, request lincoln bulletin c2.420, welding pressure pipelines. Welding rod sizes and base metal thickness chart. Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean. Lincoln electric stick welding electrode chart pdf; Web 7 rows diffusible hydrogen. Web below is a chart of the different types of stick welding rod and explanations of what the different numbers mean. We have gone into this in more detail below. Automotive & transportation high speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.; Web stick electrodes for mild and low. Alternate electrodes vertical, overhead, and horizontal. Lincoln electric stick welding electrode chart pdf; Used for welding of cast irons to other cast irons as well as for joining cast irons to mild steels and stainless steels. Web lincoln electric consumables for each application. E6010 and e6011 size and amperage chart. This article describes electrode lot numbers q1, q2, and q3 as well as. Used for welding of cast irons to other cast irons as well as for joining cast irons to mild steels and stainless steels. Lincoln electric stick welding electrode chart pdf; Web 7 rows diffusible hydrogen. Various coating types are available for a wide range of applications. Please be sure to use the notes as an aid in selecting lincoln electric consumables. Although we have offered a comprehensive table, we suggest that you use these figures as a. Web the lincoln electric company 22801 st. Smaw (1) any e70x8 electrode may be. Web baker’s electrode amperage chart; Web figure 5 is an example of a chart for selecting the proper welding cable size. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Web for vertical up and vertical down pipe welding technique, request lincoln bulletin c2.420, welding pressure pipelines. Web stick electrodes for mild and low alloy steel welding. Automotive & transportation high speed, low spatter and controlled heat input solutions that ensure repeatability and high productivity.; In this article, i’ll cover the most.

Stick Amps Vs Rod size Vs metal thickness Welding rod chart, Welding

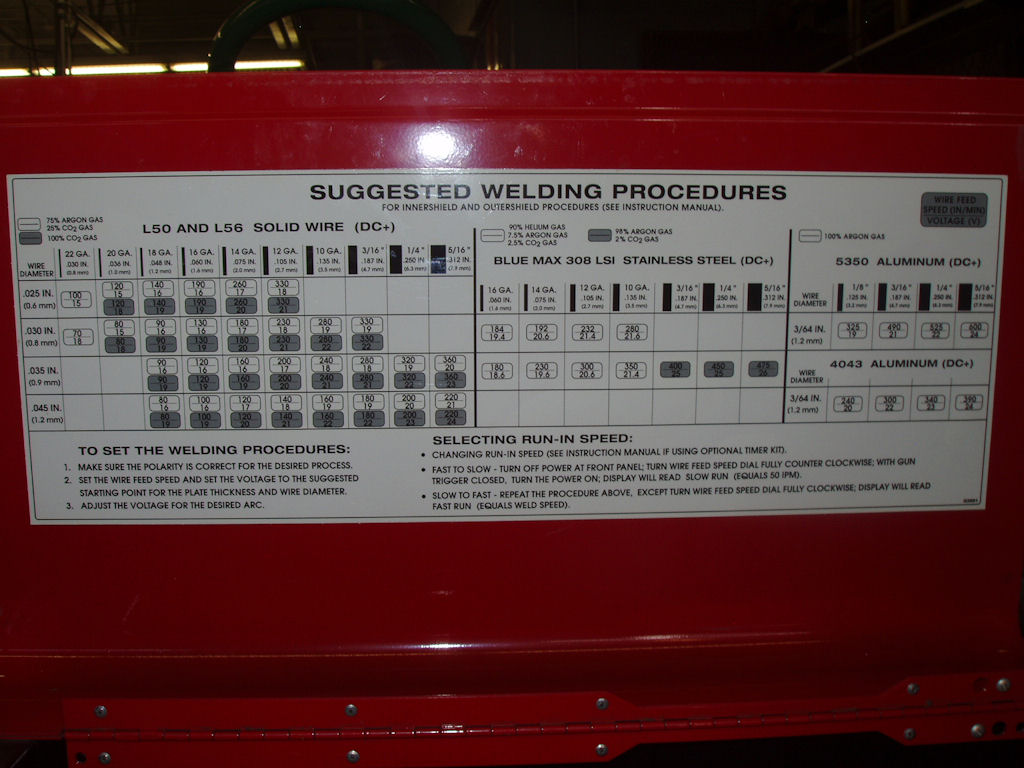

MIG welder settings explained Amperage & Wire Speed

Pin by Bill Poole on Metal fabrication Welding and fabrication

How Do I Calculate How Much Welding Rod I Need

MIG Welding Aluminum Electrodes, Gasses, Welder Setting & Equipment

The ultimate guide to welding rod sizes and classifications, including

Welding rod chart, Welding rods, Welding and fabrication

Tig Welding Rod Chart

Lincoln Welding Electrode Chart My XXX Hot Girl

Welding Rod Sizes Here's The Complete Guide

Welding Rod Sizes And Base Metal Thickness Chart.

Weld With The Electrode End Lightly Dragging On The Work To Force The.

Mig Wires And Tig Rods Filler Metals Made From The.

Other Charts Are Available From Cable Manufacturers And Welding Reference Books.

Related Post: