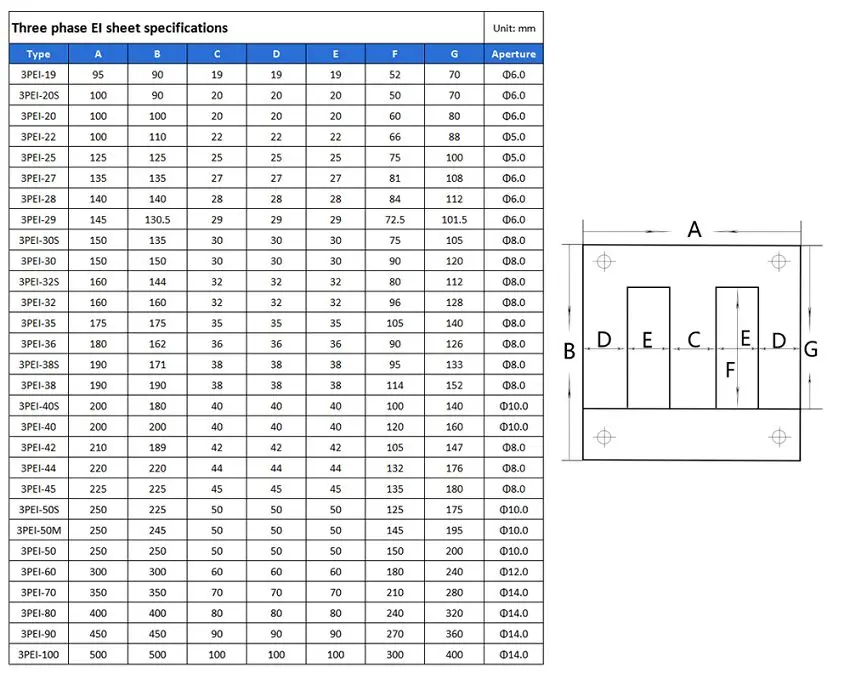

Lamination Thickness Chart

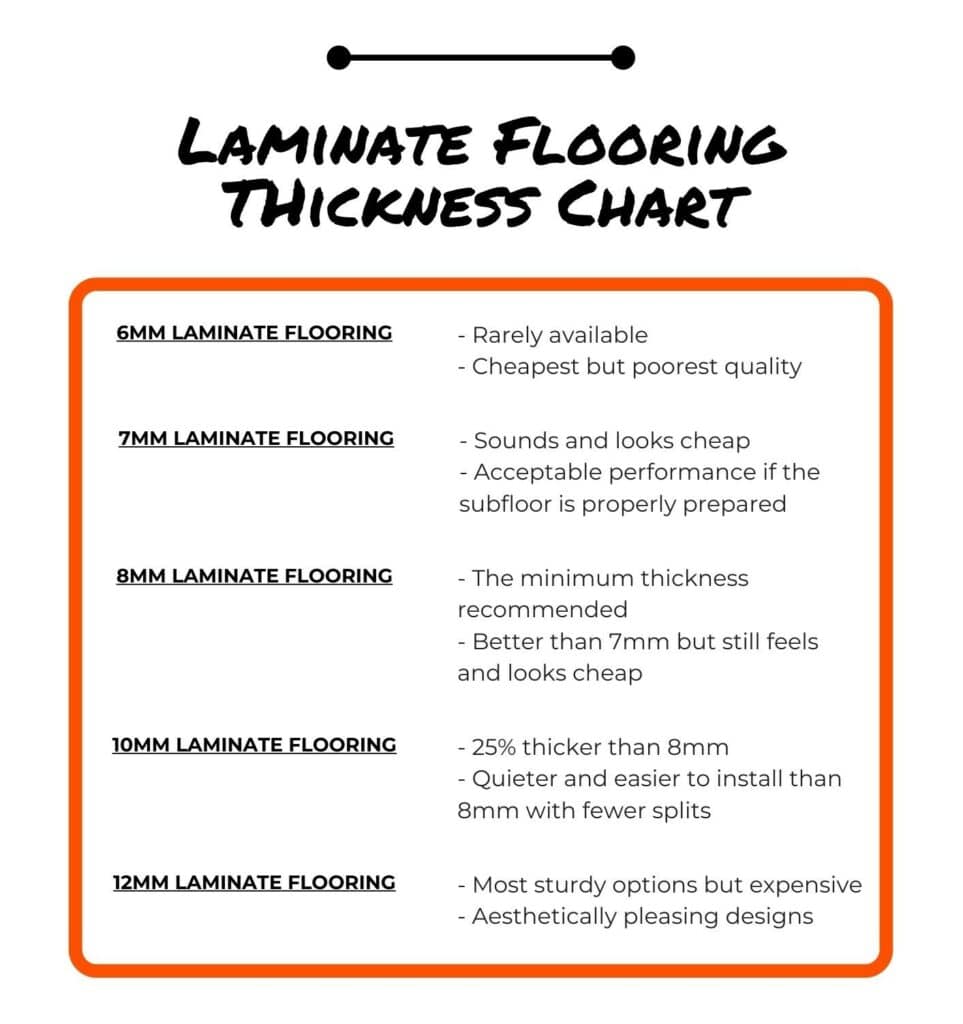

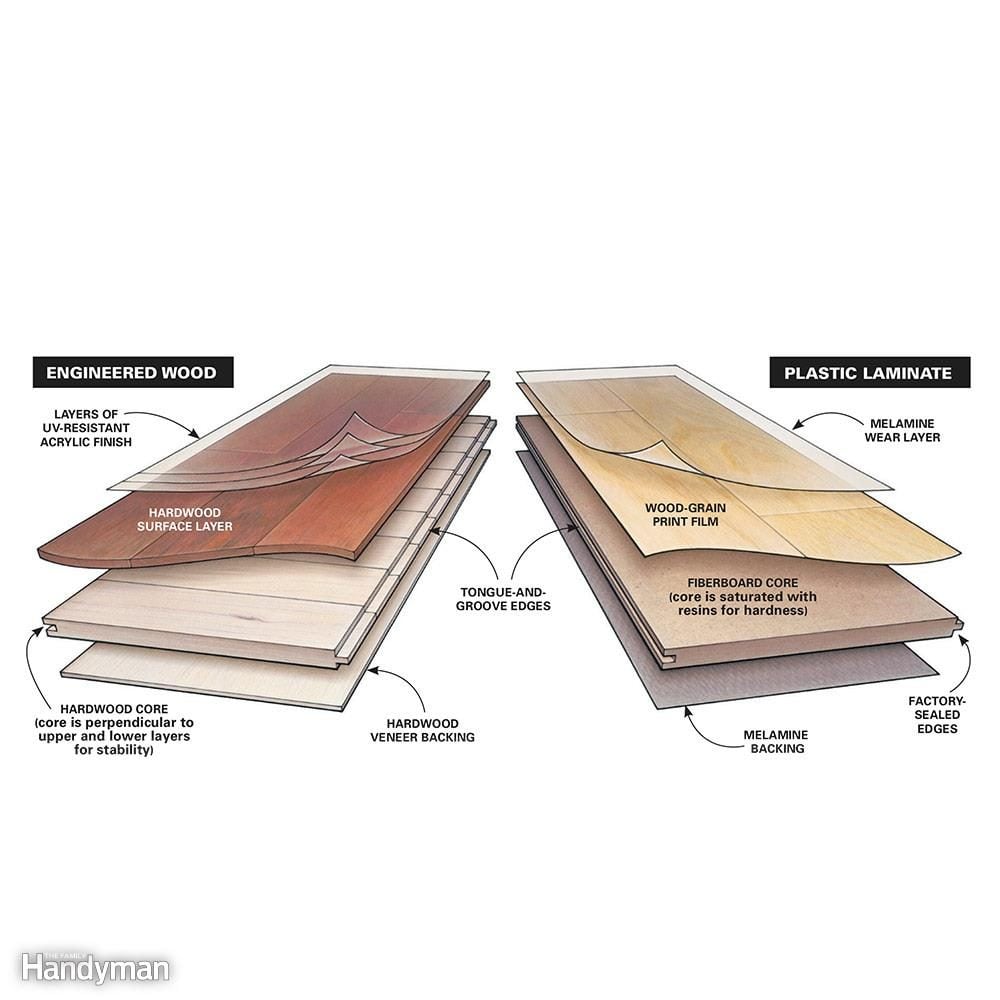

Lamination Thickness Chart - Naturally, a higher laminate thickness will make it difficult to fold the document. Web although, if your piece needs to be folded, it is better to go with a laminate that is 3 mils or less. It’s also something that can have a dramatic impact on certain types of. Frequently asked questions (faq) about. Instructional materials, dry/wet erase memo boards, charts and diagrams, event passes and bookmarks are some more common applications of. Glass fabric is available in different roll widths and thicknesses. How to choose the right laminated glass thickness? Factors affecting laminated glass thickness. Likewise, a film measuring 10mil would be.010 thick. Web while you can find a variety of products on the market today, laminate flooring is between 6mm and 12mm in thickness, with 6mm styles being quite thin and 12mm designs on the very heavy side. Here are the most common thicknesses of laminating film and popular applications for each size: Web while you can find a variety of products on the market today, laminate flooring is between 6mm and 12mm in thickness, with 6mm styles being quite thin and 12mm designs on the very heavy side. Web laminating film thickness is measured in mils. Productivity. Web 8mm vs 10mm laminate. Web when it comes to selecting the appropriate laminating film thickness, there are several factors to consider. If cost is a concern and you have a smooth subfloor, you can get by with 7 or 8mm. Web available in 200”, 400” or 600” lengths. Our planks come in the three thickest measurements: Web laminates with 150 micron thickness are often used for flat pieces that are handled on a regular basis. Web laminating film thickness is measured in mils. Web before lamination, the thickness of the coated films was ~20 µm and ~60 µm for the coated ag and carbon layers, respectively. 200” is ideal for lower volume use. Recommended for both. Web 8mm vs 10mm laminate. Factors affecting laminated glass thickness. Likewise, a film measuring 10mil would be.010 thick. In other words, they go from thin to thick. Web the most common roll lamination film thicknesses are 1.5,1.7, 3, 5 and 10 mil. Recommended for both horizontal and vertical applications where maximum impact resistance and durability are required. How to choose the right laminated glass thickness? Understanding these factors, debunking common misconceptions, and following helpful tips will guide you in choosing the right thickness for your specific laminating needs. Laminate thickness is the distance in millimeters from the base to the top of. Instructional materials, dry/wet erase memo boards, charts and diagrams, event passes and bookmarks are some more common applications of. Whether you’re interested in purchasing hardwood, luxury vinyl, or linoleum, thickness is an important specification homeowners should be aware of. Productivity enhancement through lean manufacturing, re engineered processes. The first thing to consider is what you are laminating. Laminate thickness is. Naturally, a higher laminate thickness will make it difficult to fold the document. Factors affecting laminated glass thickness. Web the most common roll lamination film thicknesses are 1.5,1.7, 3, 5 and 10 mil. Glass fabric is available in different roll widths and thicknesses. It’s also something that can have a dramatic impact on certain types of. A mil is simply the equivalent of 0.001 th of an inch, so it’s pretty tiny. Web wilsonart by you laminates conform to the relevant standards of the american national standards institute, for thickness, performance properties and appearance. Web before lamination, the thickness of the coated films was ~20 µm and ~60 µm for the coated ag and carbon layers,. Mentioned below are the common laminate thicknesses and some of their most popular applications. Why is choosing the right thickness for laminate important? Contains plasticizers for good flexibility. Here’s a rundown of the common thicknesses and what they’re good for. Web laminating film thickness is measured in mils. 8 millimeter (8 mm), 10 millimeter (10 mm) and 12 millimeter (12 mm). Here’s a rundown of the common thicknesses and what they’re good for. What material was the item originally printed on. Factors affecting laminated glass thickness. Web when it comes to selecting the appropriate laminating film thickness, there are several factors to consider. Maintenance and care of laminated glass. Here’s a rundown of the common thicknesses and what they’re good for. Why is choosing the right thickness for laminate important? The chart below illustrates the approximate temperature at which the adhesive is activated and is ready Web laminates with 150 micron thickness are often used for flat pieces that are handled on a regular basis. Mentioned below are the common laminate thicknesses and some of their most popular applications. In other words, they go from thin to thick. 8 millimeter (8 mm), 10 millimeter (10 mm) and 12 millimeter (12 mm). Web while you can find a variety of products on the market today, laminate flooring is between 6mm and 12mm in thickness, with 6mm styles being quite thin and 12mm designs on the very heavy side. .048???/1.2mm) the most commonly used grade; Web temperatures depending upon the type of adhesive that is used, the thickness of the laminate and whether a cardboard carrier is used. We’ve been digging into the ins and outs of lamination to create a guide to laminating pouches (sizes, uses, and how to use them.) learn how to use thermal laminating pouches and laminating sheets, and which product will best suit your needs. Laminate thickness is the distance in millimeters from the base to the top of the laminate board. Web lamination film is measured in mil thicknesses. Contains plasticizers for good flexibility. As you might expect, the thinner the plank the less expensive the laminate floor.

Know your Microns Hot Dip Galvanized Steel Coating Thickness

FR4 measurement tolerances Valuable Tech Notes

Lamination Sizes

Laminate Floor Thickness Buying Guide Floor Critics

How to Choose Laminate Flooring A Buyer's Guide The Family Handyman

Patent EP0059079B1 Metalthermoplasticmetal laminates Google Patents

Patent EP0670779A1 A system of electronic laminates with improved

23 Sizes of Laminating Pouches

Structure thickness after lamination process. Download Scientific Diagram

Total losses as a function of lamination thickness

Web Wilsonart By You Laminates Conform To The Relevant Standards Of The American National Standards Institute, For Thickness, Performance Properties And Appearance.

Our Planks Come In The Three Thickest Measurements:

Productivity Enhancement Through Lean Manufacturing, Re Engineered Processes.

Glass Fabric Is Available In Different Roll Widths And Thicknesses.

Related Post: