Kennametal Material Group Chart

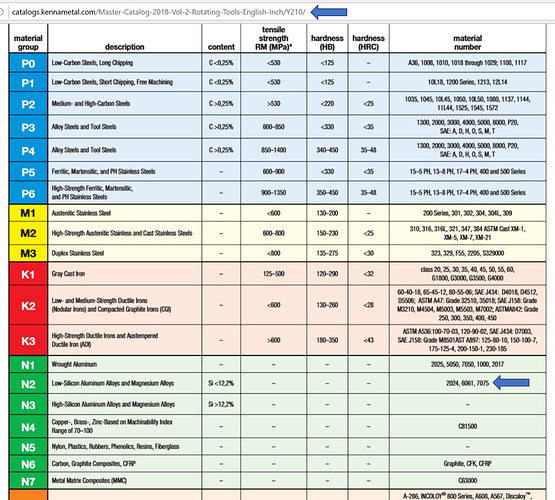

Kennametal Material Group Chart - Web kennametal inserts grade naming system a system of grades, geometries, and application guidelines to provide optimal solutions for your metalcutting needs. Web google was not very helpful with decoding the material groups either, so here is what kennametal tech support offered: Titanium is one of the fastest growing materials used in aerospace applications. Web have the catalog (s) of your choice shipped directly to you. Web kennametal’s speeds and feeds calculator streamlines the calculation of rates using either the metric or english system of weights and measures. Web iso material groups chart. All the players in the industry use the german iso standard (also nicknamed “pmk”) for classifying the six main raw material groups. The k68 grade has excellent abrasion resistance for machining cast irons,. We use the pmk convention that is used in most of the cutting tool. Stellite 12 is a weldable alloy composed of cobalt, chrome, and tungsten with high toughness and. Web kennametal inserts grade naming system a system of grades, geometries, and application guidelines to provide optimal solutions for your metalcutting needs. Web cemented tungsten carbide grades for saw tips and engineered components. Examples of materials in each of these categories are provided for easy reference. Web have the catalog (s) of your choice shipped directly to you. The k68. How to understand and make the most out of our grade tables. Web google was not very helpful with decoding the material groups either, so here is what kennametal tech support offered: Web kennametal grooving grades chart. Kennametal metalworking catalogs for download. Examples of materials in each of these categories are provided for easy reference. The k68 grade has excellent abrasion resistance for machining cast irons,. Web workpiece materials have been categorized within their iso application range. Web this numbering system chart from the kennametal innovations catalog provides a guide to the company’s extensive assortment of turning inserts. A system of grades, geometries, and application guidelines to provide optimal solutions. Kennametal metalworking catalogs for download. We use the pmk convention that is used in most of the cutting tool. Examples of materials in each of these categories are provided for easy reference. Web kennametal grooving grades chart. Web workpiece materials have been categorized within their iso application range. Web iso material groups chart. A system of grades, geometries, and application guidelines to provide optimal solutions. We use the pmk convention that is used in most of the cutting tool. Cd750 only available as standard edm block. Web google was not very helpful with decoding the material groups either, so here is what kennametal tech support offered: Web have the catalog (s) of your. Web to make this choice easier, workpiece materials are divided into six major groups, in accordance with iso standards, and each group has unique properties regarding. Web kennametal inserts grade naming system a system of grades, geometries, and application guidelines to provide optimal solutions for your metalcutting needs. Web *kennametal application specialists should be consulted to assist in grade selection.. Kc850 exsists, but it is not recomended by kennametal for any application in their catalogs. Web kennametal inserts grade naming system a system of grades, geometries, and application guidelines to provide optimal solutions for your metalcutting needs. The machining doctor's complete list of materials according to the vdi 3323 group classification. All the players in the industry use the german. Web workpiece materials have been categorized within their iso application range. Web cemented tungsten carbide grades for saw tips and engineered components. Kc850 exsists, but it is not recomended by kennametal for any application in their catalogs. We use the pmk convention that is used in most of the cutting tool. Web kennametal grooving grades chart. The prime rationale for designers to chose titanium in their designs is its. Web workpiece materials have been categorized within their iso application range. How to understand and make the most out of our grade tables. Web cemented tungsten carbide grades for saw tips and engineered components. Web this numbering system chart from the kennametal innovations catalog provides a guide. Web *kennametal application specialists should be consulted to assist in grade selection. Cd750 only available as standard edm block. Cemented tungsten carbide grades for metal forming and wear components. A system of grades, geometries, and application guidelines to provide optimal solutions. The k68 grade has excellent abrasion resistance for machining cast irons,. Cd750 only available as standard edm block. We use the pmk convention that is used in most of the cutting tool. Examples of materials in each of these categories are provided for easy reference. Web to make this choice easier, workpiece materials are divided into six major groups, in accordance with iso standards, and each group has unique properties regarding. Web kennametal’s speeds and feeds calculator streamlines the calculation of rates using either the metric or english system of weights and measures. Web kennametal grooving grades chart. Web *kennametal application specialists should be consulted to assist in grade selection. Web workpiece materials have been categorized within their iso application range. How to understand and make the most out of our grade tables. The machining doctor's complete list of materials according to the vdi 3323 group classification. Kc850 exsists, but it is not recomended by kennametal for any application in their catalogs. It allows you to accurately. All the players in the industry use the german iso standard (also nicknamed “pmk”) for classifying the six main raw material groups. Web grade specifications and application chart. Web google was not very helpful with decoding the material groups either, so here is what kennametal tech support offered: Titanium is one of the fastest growing materials used in aerospace applications.

Carbide Insert Grade Comparison Chart Images

CATALOGO KENNAMETAL PDF

Origin/consistency of chipload Shapeoko Carbide 3D

Kennametal Material Group Chart

金属成型

Kennametal Speeds And Feeds Chart Kanmer

Kennametal A4 Groove & Turn Insert Designation Chart

Kennametal Solid Carbide End Mill Tool Selection Guide Fractional Sizes

Carbide Drill Bit Size Chart

Drill Feed Speed Chart

The Prime Rationale For Designers To Chose Titanium In Their Designs Is Its.

The K68 Grade Has Excellent Abrasion Resistance For Machining Cast Irons,.

Cemented Tungsten Carbide Grades For Metal Forming And Wear Components.

Web Cemented Tungsten Carbide Grades For Saw Tips And Engineered Components.

Related Post: