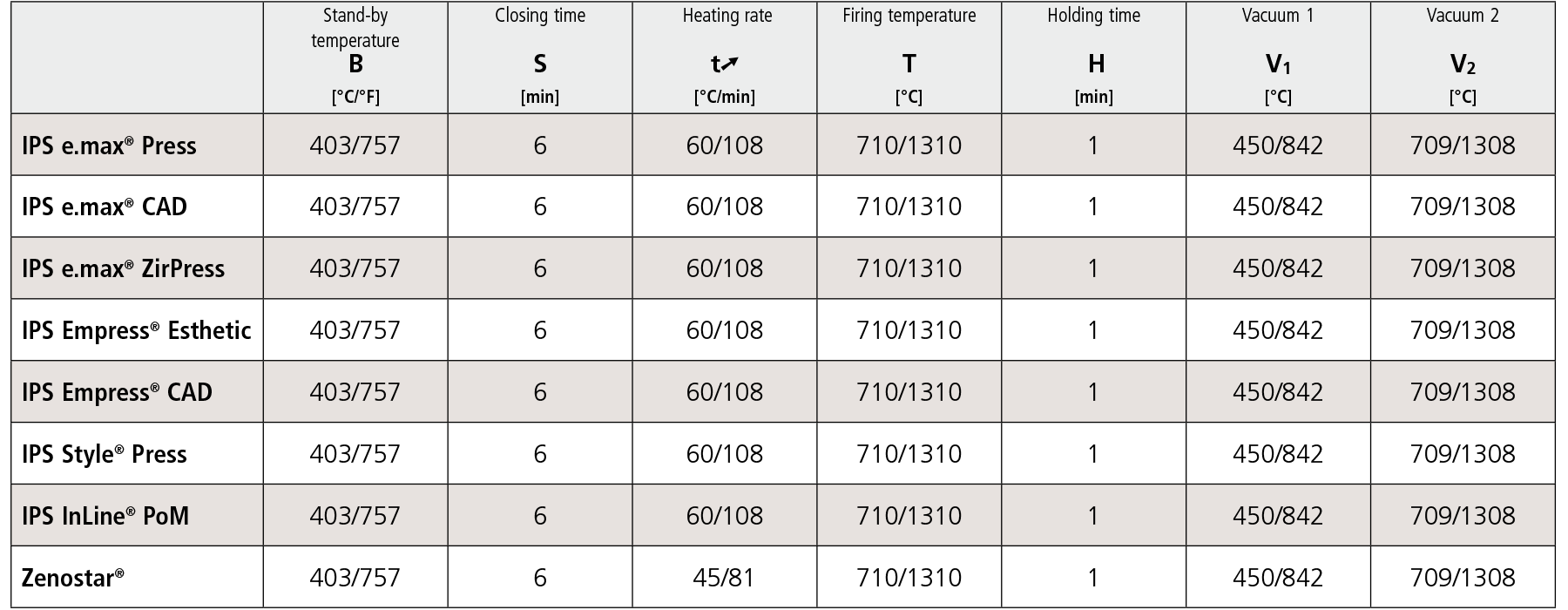

Ivoclar Emax Ceram Firing Chart

Ivoclar Emax Ceram Firing Chart - P3 (~15min) p1 (~24min) p7 (~31min) p1 (~24min) small speed tray. The shade guides of the ips e.max® ceram materials are an integral part of the product concept. As ips e.max zirpress ingots are available for both the staining. Web firing parameters for the stain/glaze firing with ips ivocolor shade, essence, glaze. Dentin1 for emax for multimat: Additionally, the programat p510 and p710 furnaces are equipped with an infrared thermal camera, which automatically. Web this video will teach you the layering of ips e.max ceram on the ips e.max press structure and not avoid the manual part, which is grinding of ceramic restorations to a natural. * irt standard mode ** if the layer thickness is more than 2 mm on the ips e.max cad. Web multiple firing cycles, i can achieve ceramic shoulders with excellent fit and firing stability, also in the pontic area. Web you must replace in firing parameters in emax b=403 celcius with v1=450 celsius. Dentin1 for emax for multimat: As ips e.max zirpress ingots are available for both the staining. Given its universal characteristics and low firing temperature (710 °c/ 1310 °f), ips ivocolor is also suited for use in conjunction with various other ivoclar. Web firing parameters for the stain/glaze firing with ips ivocolor shade, essence, glaze. This leads to a change in. P3 (~15min) p1 (~24min) p7 (~31min) p1 (~24min) small speed tray. The shade guides and the individual shade tabs can. Web instructions for use (eifu) firing parameters. * irt standard mode ** if the layer thickness is more than 2 mm on the ips e.max cad. This leads to a change in the microstructure in the ips e.max. As ips e.max zirpress ingots are available for both the staining. Given its universal characteristics and low firing temperature (710 °c/ 1310 °f), ips ivocolor is also suited for use in conjunction with various other ivoclar. Web press and firing parameters 69 layering technique finishing veneering with ips e.max ceram procedure for ho ingots 42 ips e.max press (monochromatc ingots). This leads to a change in the microstructure in the ips e.max. Given its universal characteristics and low firing temperature (710 °c/ 1310 °f), ips ivocolor is also suited for use in conjunction with various other ivoclar. Web press and firing parameters 69 layering technique finishing veneering with ips e.max ceram procedure for ho ingots 42 ips e.max press (monochromatc. Web the furnaces impress with excellent firing results. Web firing parameters for the stain/glaze firing with ips ivocolor shade, essence, glaze. Web instructions for use (eifu) firing parameters. The shade guides of the ips e.max® ceram materials are an integral part of the product concept. As ips e.max zirpress ingots are available for both the staining. Given its universal characteristics and low firing temperature (710 °c/ 1310 °f), ips ivocolor is also suited for use in conjunction with various other ivoclar. P3 (~15min) p1 (~24min) p7 (~31min) p1 (~24min) small speed tray. As ips e.max zirpress ingots are available for both the staining. Web multiple firing cycles, i can achieve ceramic shoulders with excellent fit and. Dentin1 for emax for multimat: P3 (~15min) p1 (~24min) p7 (~31min) p1 (~24min) small speed tray. This leads to a change in the microstructure in the ips e.max. Web instructions for use (eifu) firing parameters. Heating rate heizrate t1 °c/min / °f/min 90 / 162 90 / 162 90. As ips e.max zirpress ingots are available for both the staining. * irt standard mode ** if the layer thickness is more than 2 mm on the ips e.max cad. Web you must replace in firing parameters in emax b=403 celcius with v1=450 celsius. The shade guides of the ips e.max® ceram materials are an integral part of the product. As ips e.max zirpress ingots are available for both the staining. Given its universal characteristics and low firing temperature (710 °c/ 1310 °f), ips ivocolor is also suited for use in conjunction with various other ivoclar. P3 (~15min) p1 (~24min) p7 (~31min) p1 (~24min) small speed tray. Web press and firing parameters 69 layering technique finishing veneering with ips e.max. Web instructions for use (eifu) firing parameters. Dentin1 for emax for multimat: P3 (~15min) p1 (~24min) p7 (~31min) p1 (~24min) small speed tray. Web multiple firing cycles, i can achieve ceramic shoulders with excellent fit and firing stability, also in the pontic area. This leads to a change in the microstructure in the ips e.max. Heating rate heizrate t1 °c/min / °f/min 90 / 162 90 / 162 90. Web you must replace in firing parameters in emax b=403 celcius with v1=450 celsius. P3 (~15min) p1 (~24min) p7 (~31min) p1 (~24min) small speed tray. The shade guides and the individual shade tabs can. Given its universal characteristics and low firing temperature (710 °c/ 1310 °f), ips ivocolor is also suited for use in conjunction with various other ivoclar. Additionally, the programat p510 and p710 furnaces are equipped with an infrared thermal camera, which automatically. Web firing parameters for the stain/glaze firing with ips ivocolor shade, essence, glaze. * irt standard mode ** if the layer thickness is more than 2 mm on the ips e.max cad. Web press and firing parameters 69 layering technique finishing veneering with ips e.max ceram procedure for ho ingots 42 ips e.max press (monochromatc ingots) sprueing,. Dentin1 for emax for multimat: Web the furnaces impress with excellent firing results. This leads to a change in the microstructure in the ips e.max. Firing behaviour and firing process. Web multiple firing cycles, i can achieve ceramic shoulders with excellent fit and firing stability, also in the pontic area.

Programat ® EP 3000—firing and glaze protocols for e.Max Ceram and

IPS Ivocolor DentalTechTips

1. Firing schedules for the zirconia copings, the IPS e.max ® Ceram

Firing parameters Ivoclar Vivadent IPS e.max CAD Flow Chart 3unit

emax CeramVAe.qxd by Ivoclar Vivadent Issuu

IPS E.MAX CERAM SELECTION KIT DJL Dental Tienda Online

Ivoclar Vivadent IPS e.max Ceram Impulse Occlusal Dentinmasse

IPS e.max Ceram shade guide impulse Sanitaria.hr

emax Kristallisation.qxd by Ivoclar Vivadent Issuu

CDOCS Ivoclar Impulse Blocks

Web This Video Will Teach You The Layering Of Ips E.max Ceram On The Ips E.max Press Structure And Not Avoid The Manual Part, Which Is Grinding Of Ceramic Restorations To A Natural.

The Shade Guides Of The Ips E.max® Ceram Materials Are An Integral Part Of The Product Concept.

As Ips E.max Zirpress Ingots Are Available For Both The Staining.

Web Instructions For Use (Eifu) Firing Parameters.

Related Post: