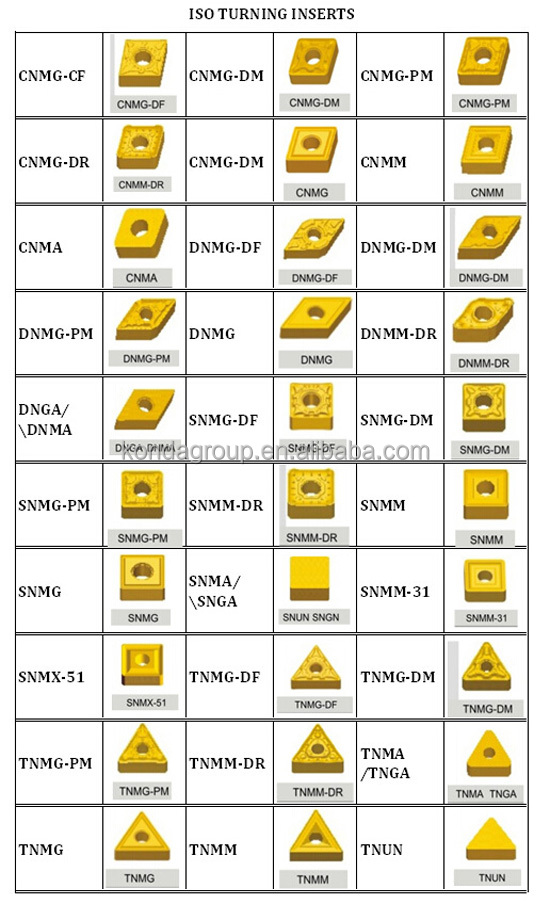

Insert Geometry Chart

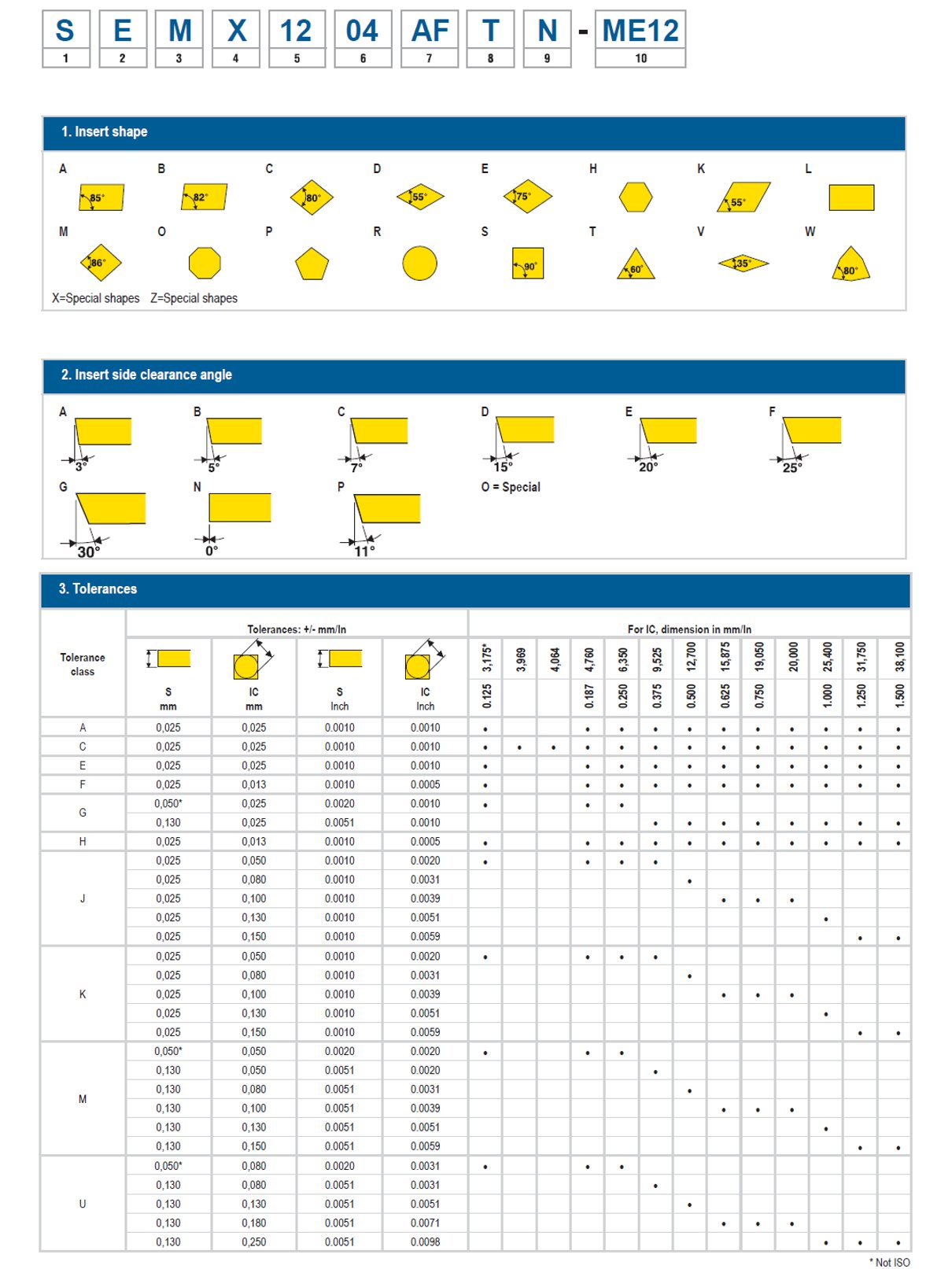

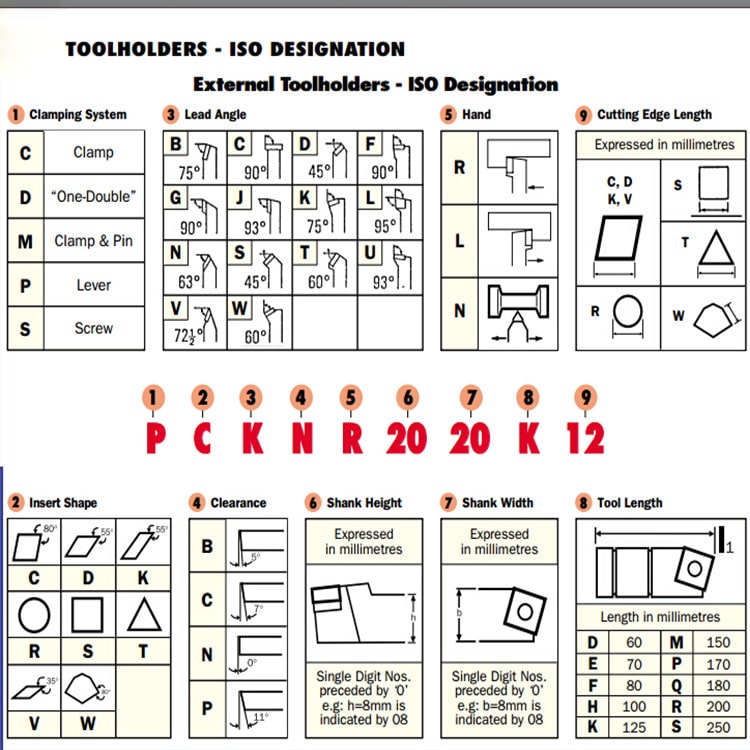

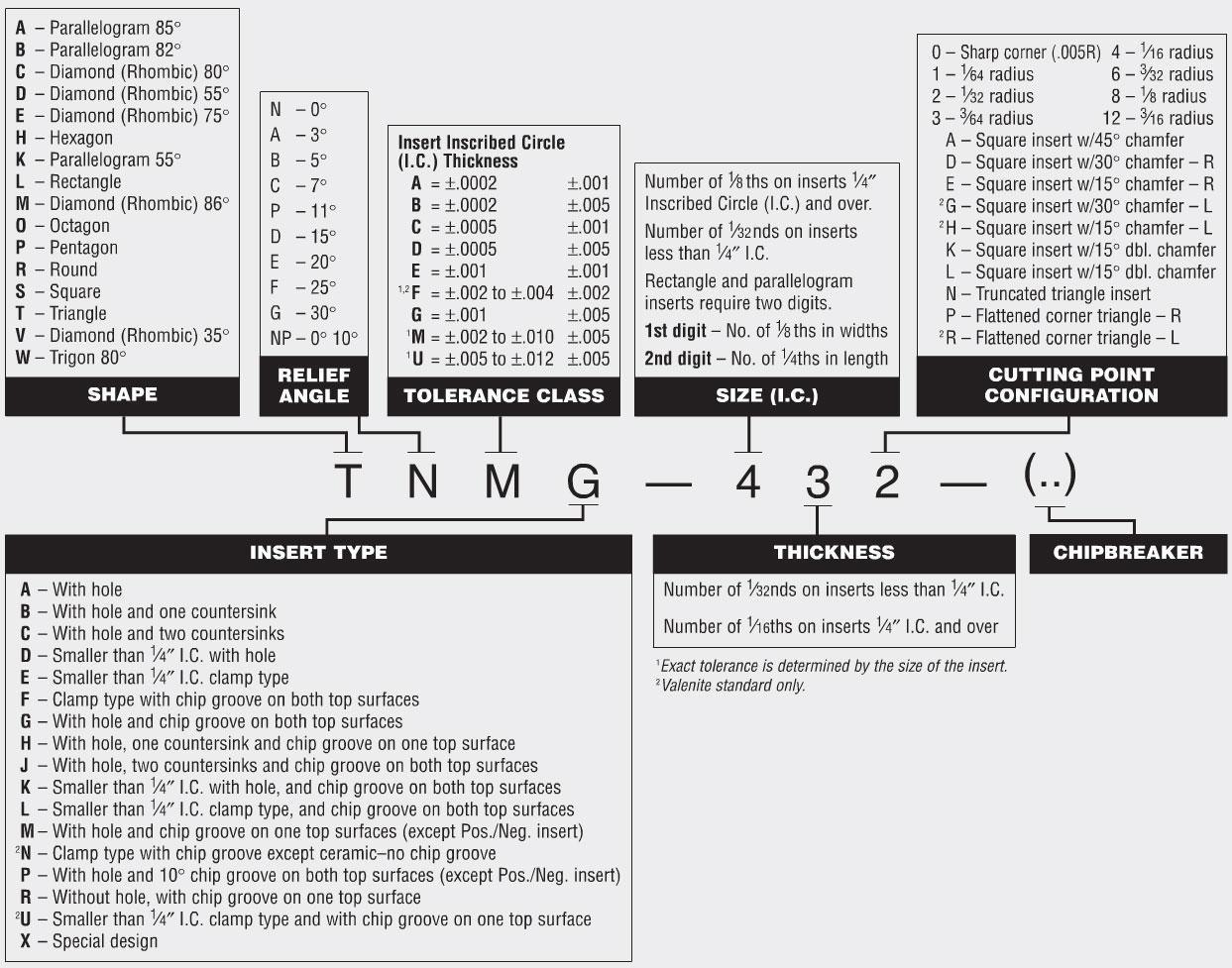

Insert Geometry Chart - Turning of all materials and. Web download your key to understanding the insert code system! Web this numbering system chart from the kennametal innovations catalog provides a guide to the company’s extensive assortment of turning inserts. Web just understand the basics of insert cutting edges from this document and select the correct insert. Find replacement tool based on geometry or grade. Find comprehensive turning insert designation system reference tables and examples that list. Each alphabet and number in the name signifies an aspect of the insert’s. It can dramatically reduce cycle time, improve quality, reduce. Our inserts give you the cutting edges you need to control downtime. The use of either 55° or 35°. Turning of all materials and. Web inserts are known by an iso naming convention that describes their shape and size. Find replacement tool based on geometry or grade. The use of either 55° or 35°. Web this numbering system chart from the kennametal innovations catalog provides a guide to the company’s extensive assortment of turning inserts. Chipbreaker and clamping system 5. However, it is essential for copy machining. Kennametal top notch is the way to go when it comes to quality profiling inserts. Web inserts are known by an iso naming convention that describes their shape and size. Web the insert itself has less cutting edge strength when compared with other inserts geometries. It can dramatically reduce cycle time, improve quality, reduce. Get to know carbide insert. Web how to decode a carbide insert for correct selection of insert for your application in simple and easy way summarized in 8 steps. Find comprehensive turning insert designation system reference tables and examples that list. The use of either 55° or 35°. Find comprehensive turning insert designation system reference tables and examples that list. Web the insert itself has less cutting edge strength when compared with other inserts geometries. Turning of all materials and. Each alphabet and number in the name signifies an aspect of the insert’s. Web this numbering system chart from the kennametal innovations catalog provides a guide to the. Web indexable and solid carbide insert conversion guide. Find comprehensive turning insert designation system reference tables and examples that list. The insert identifier app helps you find the sandvik coromant equivalent to the insert you currently. Chipbreaker and clamping system 5. Web how to decode a carbide insert for correct selection of insert for your application in simple and easy. Web this numbering system chart from the kennametal innovations catalog provides a guide to the company’s extensive assortment of turning inserts. However, it is essential for copy machining. Each alphabet and number in the name signifies an aspect of the insert’s. Web the insert itself has less cutting edge strength when compared with other inserts geometries. Web indexable and solid. Kennametal top notch is the way to go when it comes to quality profiling inserts. Find replacement tool based on geometry or grade. Web download your key to understanding the insert code system! However, it is essential for copy machining. Each alphabet and number in the name signifies an aspect of the insert’s. Web download your key to understanding the insert code system! Web inserts are known by an iso naming convention that describes their shape and size. Each alphabet and number in the name signifies an aspect of the insert’s. The use of either 55° or 35°. Polished high positive rake grade c23j inserts are designed for aluminum, copper and plastics use. Kennametal's competitive insert conversion guide can convert turning, holemaking and indexable milling grades or. Find comprehensive turning insert designation system reference tables and examples that list. The use of either 55° or 35°. Our inserts give you the cutting edges you need to control downtime. Web inserts are known by an iso naming convention that describes their shape and size. Turning of all materials and. Find comprehensive turning insert designation system reference tables and examples that list. Web inserts are known by an iso naming convention that describes their shape and size. Our inserts give you the cutting edges you need to control downtime. Polished high positive rake grade c23j inserts are designed for aluminum, copper and plastics use. Each alphabet and number in the name signifies an aspect of the insert’s. Kennametal top notch is the way to go when it comes to quality profiling inserts. However, it is essential for copy machining. Web inserts are known by an iso naming convention that describes their shape and size. Web the seco geometry naming convention provides guidance as to how geometry affects the insert’s cutting action. Get to know carbide insert. Find comprehensive turning insert designation system reference tables and examples that list. Web indexable and solid carbide insert conversion guide. Our inserts give you the cutting edges you need to control downtime. Find replacement tool based on geometry or grade. Web download your key to understanding the insert code system! Chipbreaker and clamping system 5. It can dramatically reduce cycle time, improve quality, reduce. Polished high positive rake grade c23j inserts are designed for aluminum, copper and plastics use. Web just understand the basics of insert cutting edges from this document and select the correct insert. Turning of all materials and.

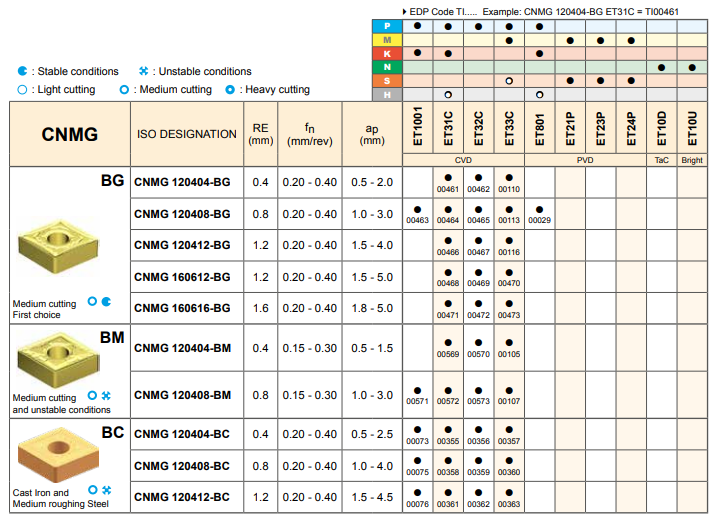

Tungsten Carbide Inserts Cnc Cutting Toolscnmg Cvd/pvd Coated Buy

Factory Outlet Tooling Insert Shapes

ISO designation for Inserts Seco Tools

How to choose the turning insert angle Meetyou Carbide

Exclusive Web Offer 10pcs SC1204 Carbide Insert Turning Blade Lathe

Carbide Insert Model

Geometry Formulas Chart 8 X 10 Etsy

Printable Elementary Geometry Skills Chart

Carbide Insert Identification Chart A Visual Reference of Charts

Geometry Reference Sheet

Web This Numbering System Chart From The Kennametal Innovations Catalog Provides A Guide To The Company’s Extensive Assortment Of Turning Inserts.

Kennametal's Competitive Insert Conversion Guide Can Convert Turning, Holemaking And Indexable Milling Grades Or.

The Use Of Either 55° Or 35°.

Web How To Decode A Carbide Insert For Correct Selection Of Insert For Your Application In Simple And Easy Way Summarized In 8 Steps.

Related Post: