Idler Pulley Size Chart

Idler Pulley Size Chart - • robust and high quality pulley materials to withstand contaminates. To calculate supercharger speed, multiply your maximum engine speed by the pulley ratio value listed above. “u” = distance between the tensile cord and the bottom of the timing belt tooth. Web gates offers a variety of idler pulleys and sprockets for power transmission applications. Supercharger speeds above 23,000 rpm are not recommended. Return idlers support the belt during the return path and meet or exceed the cema load requirements. This measurement represents the diameter of the belt itself as it rides in the pulley. Divide the answer from step 2 by 72 and. Multiply the answer by the pulley’s width, and then add 6. Browse the product list by part number, type, included angle, bearing number, bore size, outside diameter and width. Web gates offers a variety of idler pulleys and sprockets for power transmission applications. Check the chart or follow the 4 steps below to determine how many strips and retainers you’ll need to cover your pulley. Web learn how to measure the outside diameter, inside diameter, width and flat diameter of your pulley or sheave to find the best replacement.. Return and flat idlers (r, rrd, f, frd, cir, cirrd, cif, & cifrd types) in b, c, d, and e series should not be used in a snub pulley type application. First, measure the outside diameter (od) of the pulley. Gates partview is your source for industrial belt technical information, cad models, diagrams & more to quickly find & assemble. Check the chart or follow the 4 steps below to determine how many strips and retainers you’ll need to cover your pulley. Certified drawings available on request. Web troughing idlers because of the long shaft length and having only two bearings. Web learn how to measure the outside diameter, inside diameter, width and flat diameter of your pulley or sheave. Web gates offers a variety of idler pulleys and sprockets for power transmission applications. To calculate supercharger speed, multiply your maximum engine speed by the pulley ratio value listed above. Certified drawings available on request. Divide the pulley’s diameter (in inches) by 2. Multiply the answer by the pulley’s width, and then add 6. Next, measure the pitch diameter (pd). Steel and thermoplastic construction provides high durability, heat dissipation, and dampening for long life. The below chart shows the pin that corresponds to various belt sizes. We appreciate your understanding and invite you to explore our other resources. Divide the pulley’s diameter (in inches) by 2. Web use them on the majority of your pulley’s diameter. Browse the product list by part number, type, included angle, bearing number, bore size, outside diameter and width. Web troughing idlers because of the long shaft length and having only two bearings. • new hardware included on some popular applications. Web the distance from the timing belt tooth bottom to. Steel and thermoplastic construction provides high durability, heat dissipation, and dampening for long life. Multiply the answer by the pulley’s width, and then add 6. The below chart shows the pin that corresponds to various belt sizes. See diagrams, tips and examples for different types of pulleys and idlers. Web the distance from the timing belt tooth bottom to the. However, the web page does not provide a size chart or a tool to select the right size for your belt drive system. “u” = distance between the tensile cord and the bottom of the timing belt tooth. Web use them on the majority of your pulley’s diameter. Gates partview is your source for industrial belt technical information, cad models,. This measurement represents the diameter of the belt itself as it rides in the pulley. Divide the pulley’s diameter (in inches) by 2. • superior bearings out perform oe idler pulleys. We appreciate your understanding and invite you to explore our other resources. Web a guide to select idlers for belt conveyors based on material characteristics, belt speed, width and. Browse the product list by part number, type, included angle, bearing number, bore size, outside diameter and width. Divide the pulley’s diameter (in inches) by 2. The below chart shows the pin that corresponds to various belt sizes. Supercharger speeds above 23,000 rpm are not recommended. Return idlers support the belt during the return path and meet or exceed the. To calculate supercharger speed, multiply your maximum engine speed by the pulley ratio value listed above. • robust and high quality pulley materials to withstand contaminates. “u” = distance between the tensile cord and the bottom of the timing belt tooth. See diagrams, tips and examples for different types of pulleys and idlers. Next, measure the pitch diameter (pd). Supercharger speeds above 23,000 rpm are not recommended. This measurement represents the diameter of the belt itself as it rides in the pulley. Web as always, gates application specialists will work with you, at no additional cost, to find your optimal power transmission solutions. Certified drawings available on request. Divide the answer from step 2 by 72 and. Commonly used with belt tensioners (sold separately), they are lightweight and corrosion and abrasion resistant. Web the distance from the timing belt tooth bottom to the tensile cord (pitch line) will determine the outside diameter (o.d.) of the timing belt pulley for any timing belt pitch/timing belt tooth profile. Check the chart or follow the 4 steps below to determine how many strips and retainers you’ll need to cover your pulley. Browse the product list by part number, type, included angle, bearing number, bore size, outside diameter and width. • new hardware included on some popular applications. Multiply the answer by the pulley’s width, and then add 6.

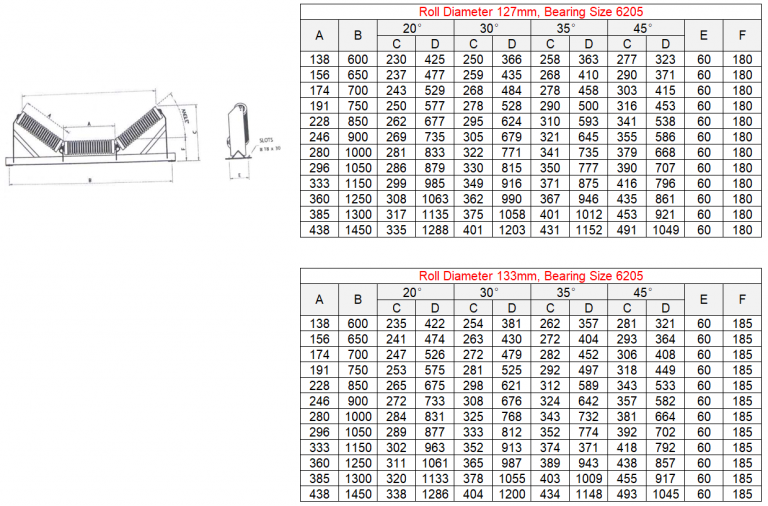

RTek International LLC Conveyor Idlers

How To Measure Belt Size For Pulley Alternator pulley size

IDLER PULLEYS Speciflcation Chart Hayden IDLER PULLEYSSpeciflcation

Dayco Premium Acc. Belt Idler Pulley

Gates Idler Pulley Size Chart

What is an Idler Pulley? Phoenix MFG

Idlers Standard Industrial Inc.

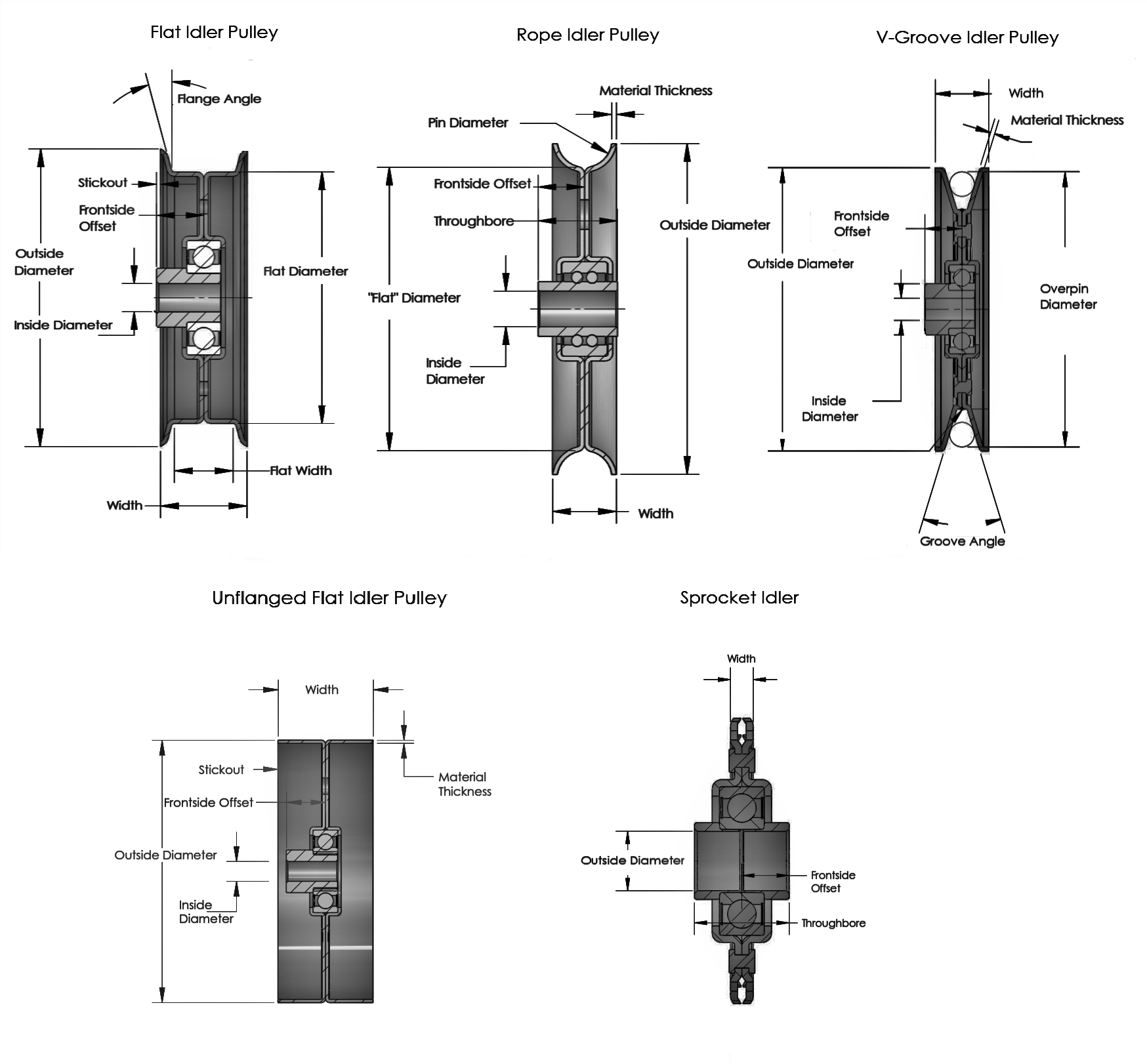

Diagrams and Definitions of Pulleys

Pulleys Timing Idler (Size Table)

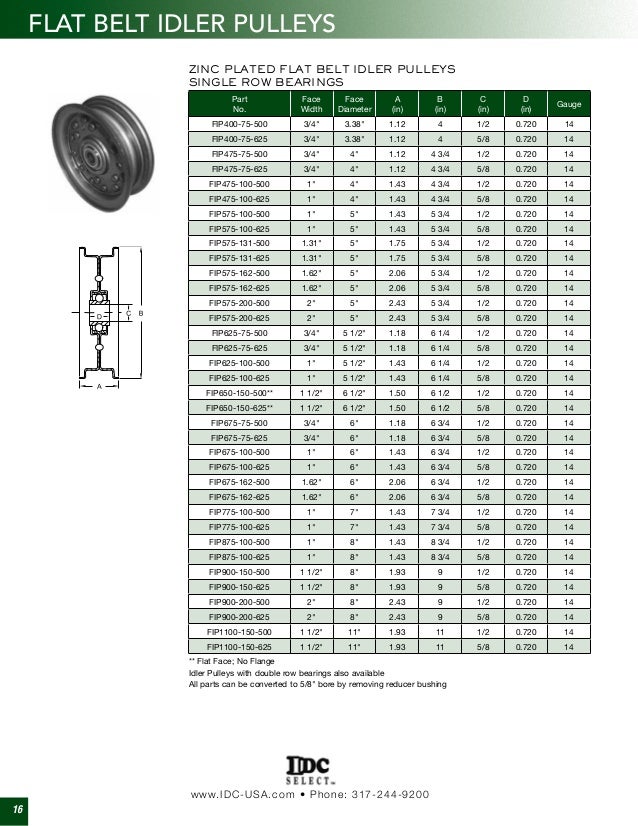

Bdidc select idlersandtensioners2011

We Appreciate Your Understanding And Invite You To Explore Our Other Resources.

Gates Partview Is Your Source For Industrial Belt Technical Information, Cad Models, Diagrams & More To Quickly Find & Assemble The.

However, The Web Page Does Not Provide A Size Chart Or A Tool To Select The Right Size For Your Belt Drive System.

The Below Chart Shows The Pin That Corresponds To Various Belt Sizes.

Related Post: