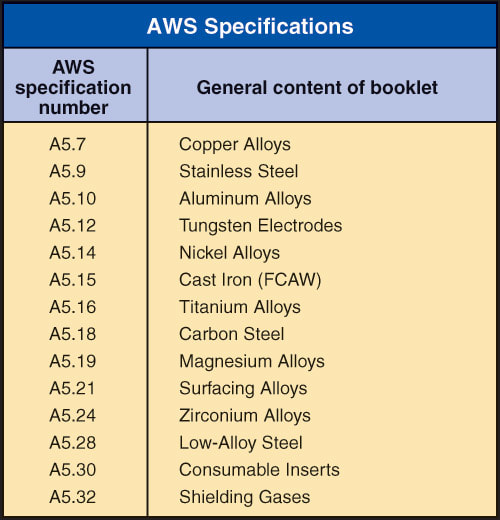

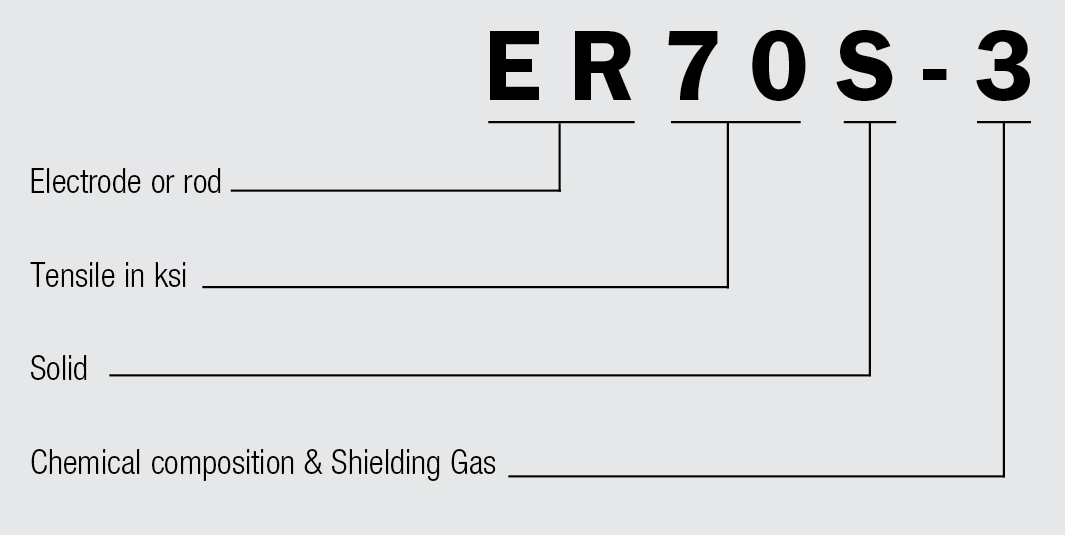

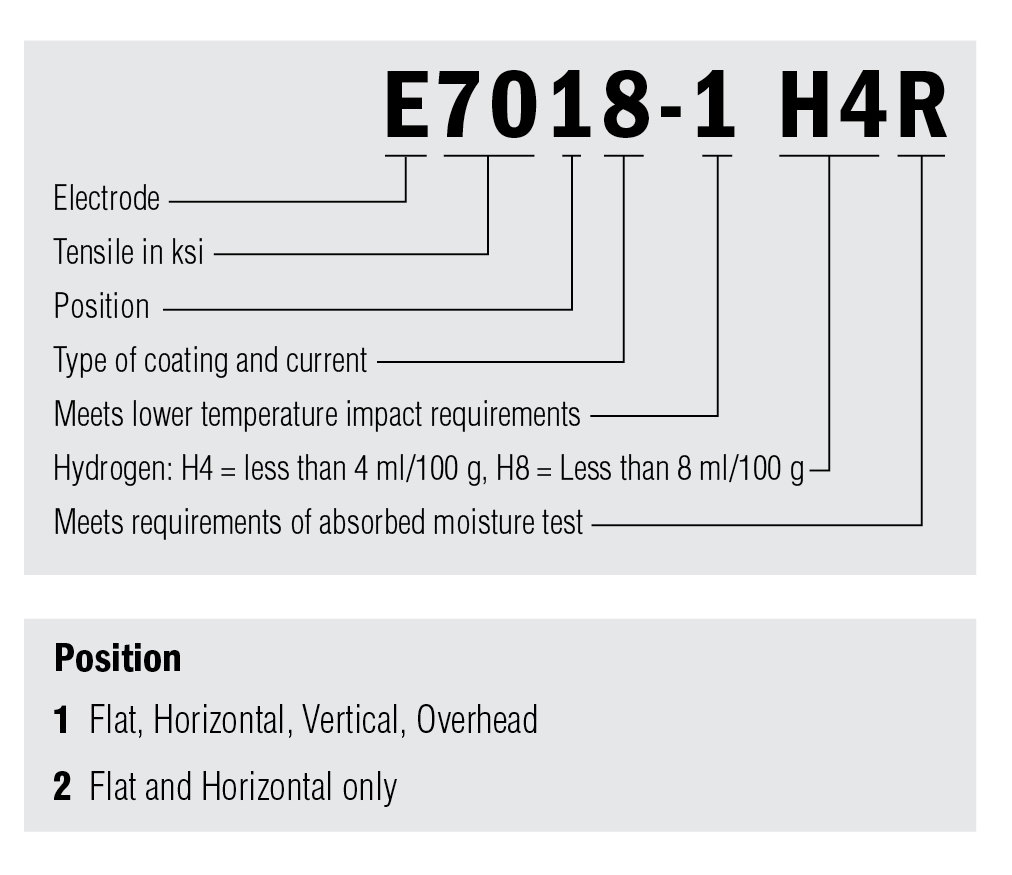

Gtaw Filler Metal Chart

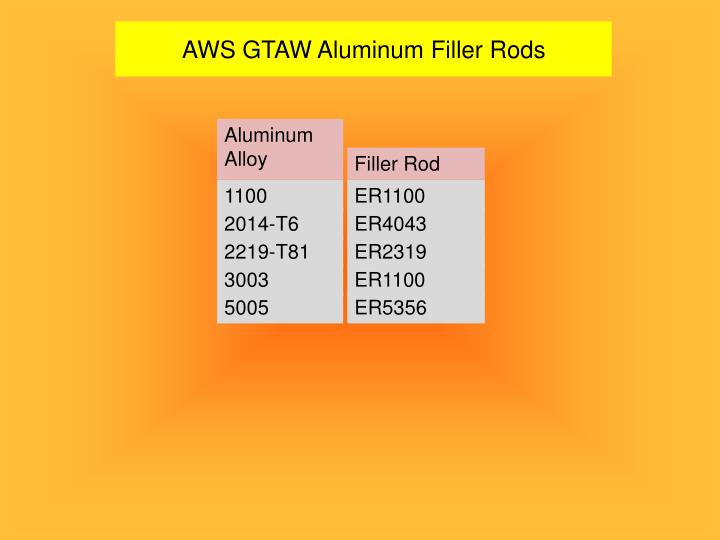

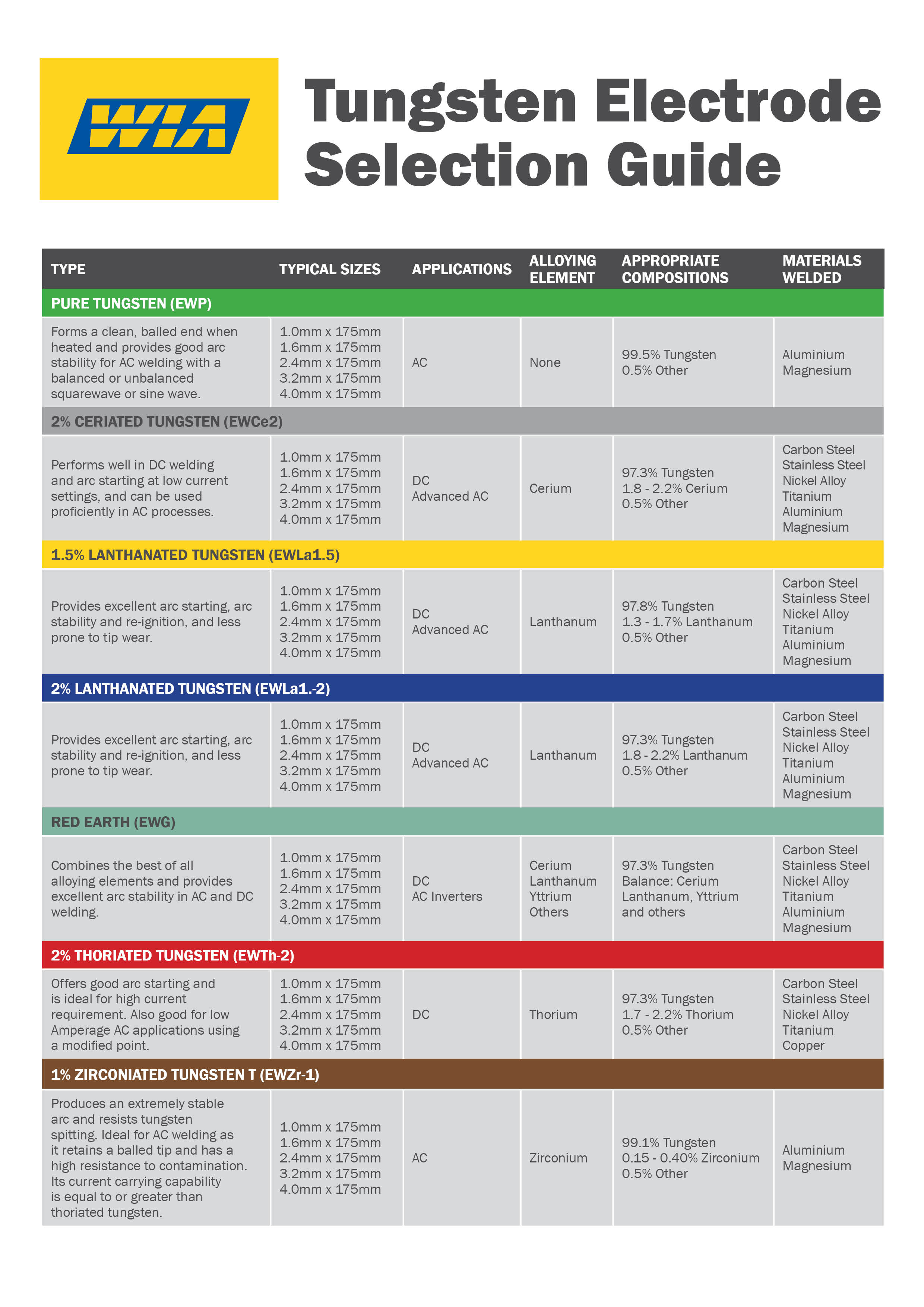

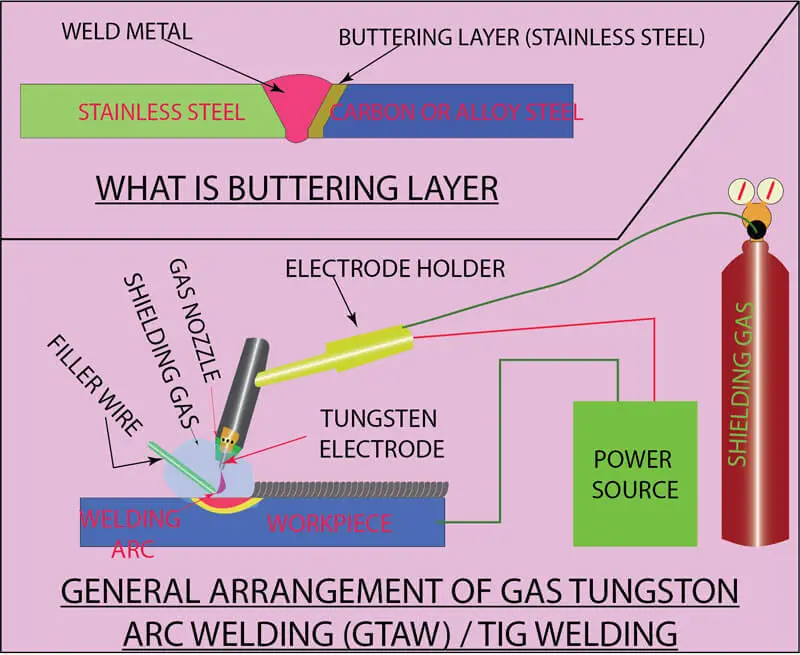

Gtaw Filler Metal Chart - These charts and explanations help demonstrate the key differences between classifications, and provide insight into other optional designators, which can be equally. Web stainless steel tig welding rods, classified in aws a5.9 specification, are widely used for fabricating and repairing metal structures. Use these charts to easily locate matching, suitable electrode or filler wire for welding to join various similar and dissimilar welding. Web gas tungsten arc welding. Web filler metal suggestions “match” the base metal properties; Deloach jr, 2nd vice chair naval surface warfare center r. Web aws fmc:2000, filler metal comparison charts, is the tenth revision of this popular comparison of trade names of welding electrodes and rods. Web weld filler metal selection chart for shielded metal arc welding (smaw) for various metal combinations: Filler metals are available with different diameters and are made of a variety of materials. Web welding electrode/ filler wire/ filler metal selection chart. Be sure you know which type of aluminum alloy you are welding, and then consult a filler metal chart. Filler metals are available with different diameters and are made of a variety of materials. Typical chemical composition of solid wire: Web examples of these critical classifications are outlined below, alongside their respective charts, for three common aws specifications for carbon. Er307si midalloy grade 307si is an austenitic stainless grade with little or no ferrite. Use these charts to easily locate matching, suitable electrode or filler wire for welding to join various similar and dissimilar welding. Er308l is primarily used for welding austenitic stainless steels such as 304 and 304l. Web as a caution, not all aluminum alloys are weldable. Web. When handling filler metal, keep it dry in an airtight box to avoid contamination and a buildup of hydrated oxide. Use only genuine replacement parts from the manufacturer. Er308l is primarily used for welding austenitic stainless steels such as 304 and 304l. Use these charts to easily locate matching, suitable electrode or filler wire for welding to join various similar. Mig wires / tig rods (gmaw/gtaw) stick electrodes (smaw) subarc (saw) copper; Web aws fmc:2000, filler metal comparison charts, is the tenth revision of this popular comparison of trade names of welding electrodes and rods. Web weld filler metal selection chart for shielded metal arc welding (smaw) for various metal combinations: Use only genuine replacement parts from the manufacturer. Web. (min.) for gtaw upto 12 mm thk. Element c mn si p s ti zr ai cu ni cr mo % 0.05 1.25 0.55 0.02 0.02 0.10 0.09 0.09 0.06 0.10 0.10 0.10 typical mechanical properties of all weld. Among the most common types of tig welding rods are er308l, er309l, er310, er316l, er321 and er347. Web aws fmc:2000, filler. In general, the important parameters include the base metal thickness, its composition, and the type of weld joint (butt vs. That is, the yield and tensile strength are expected to meet or exceed the minimum specified properties of the steel. Web aws ugfm:2010 iii personnel aws a5 committee on filler metals and allied materials j. Deloach jr, 2nd vice chair. Web stainless steel tig welding rods, classified in aws a5.9 specification, are widely used for fabricating and repairing metal structures. Web it gives radiographic quality welds. 120 °c for t < 13 interpass temp. The attached tables provide generally accepted electrode selections for the base materials shown, along with process areas that need special consideration. Matching filler metal is typically. Wehr, vice chair arcos industries llc j. Web filler metals are also used in nearly all applications of gtaw, the major exception being the welding of thin materials. Be sure you know which type of aluminum alloy you are welding, and then consult a filler metal chart. Mig wires / tig rods (gmaw/gtaw) hardfacing; Er308l is primarily used for welding. Web this article will teach you the basics of tig filler rods and help you establish your filler rod collection because 99% of the jobs are done with the rods we will discuss soon. Web gas tungsten arc welding. Web aws fmc:2000, filler metal comparison charts, is the tenth revision of this popular comparison of trade names of welding electrodes. Deloach jr, 2nd vice chair naval surface warfare center r. Wehr, vice chair arcos industries llc j. Gupta, secretary american welding society t. However, fillet welds loaded in shear seldom require Web stainless filler metal selector guide aisi type number 442 446 430f 430 fse 430 431 501 502 416 416 se 403 405 410 420 414 321 348 347. Typical chemical composition of solid wire: Web aws fmc:2000, filler metal comparison charts, is the tenth revision of this popular comparison of trade names of welding electrodes and rods. These charts and explanations help demonstrate the key differences between classifications, and provide insight into other optional designators, which can be equally. Use these charts to easily locate matching, suitable electrode or filler wire for welding to join various similar and dissimilar welding. Web examples of these critical classifications are outlined below, alongside their respective charts, for three common aws specifications for carbon steel filler metals. Use only genuine replacement parts from the manufacturer. That is, the yield and tensile strength are expected to meet or exceed the minimum specified properties of the steel. Web this article will teach you the basics of tig filler rods and help you establish your filler rod collection because 99% of the jobs are done with the rods we will discuss soon. (min.) if t > 35 mm. Filler metals are available with different diameters and are made of a variety of materials. Web welding electrode/ filler wire/ filler metal selection chart. Web weld filler metal selection chart for shielded metal arc welding (smaw) for various metal combinations: Web stainless steel tig welding rods, classified in aws a5.9 specification, are widely used for fabricating and repairing metal structures. Matching filler metal is typically required for complete joint penetration groove welds in tension. Additionally, we will give you tig filler rod charts for all standard and less often used rods, including titanium. Web filler metals are also used in nearly all applications of gtaw, the major exception being the welding of thin materials.

PPT GTAW (TIG) PowerPoint Presentation ID1860773

Tackling thin aluminum with GTAW for the first time

Get Better GTAW Results WIA

GTAW Filler Metal with a "G" suffix in ASME Sect. IX

Insider's Guide to Gas Tungsten Arc Welding (GTAW) / TIG Welding

Filler Wire Specification for Low Alloy and Stainless Steel for GTAW

Weld Filler Metal Selection Chart

7.7 Filler Metals Used with GTAW Halverson CTS

Basics of AWS Filler Metal and Electrode Classification Hobart Brothers

Basics of AWS Filler Metal and Electrode Classification Hobart Brothers

Web Filler Metal Suggestions “Match” The Base Metal Properties;

Anderson Esab Welding & Cutting Product J.

Element C Mn Si P S Ti Zr Ai Cu Ni Cr Mo % 0.05 1.25 0.55 0.02 0.02 0.10 0.09 0.09 0.06 0.10 0.10 0.10 Typical Mechanical Properties Of All Weld.

Wehr, Vice Chair Arcos Industries Llc J.

Related Post: