Grease Fitting Thread Size Chart

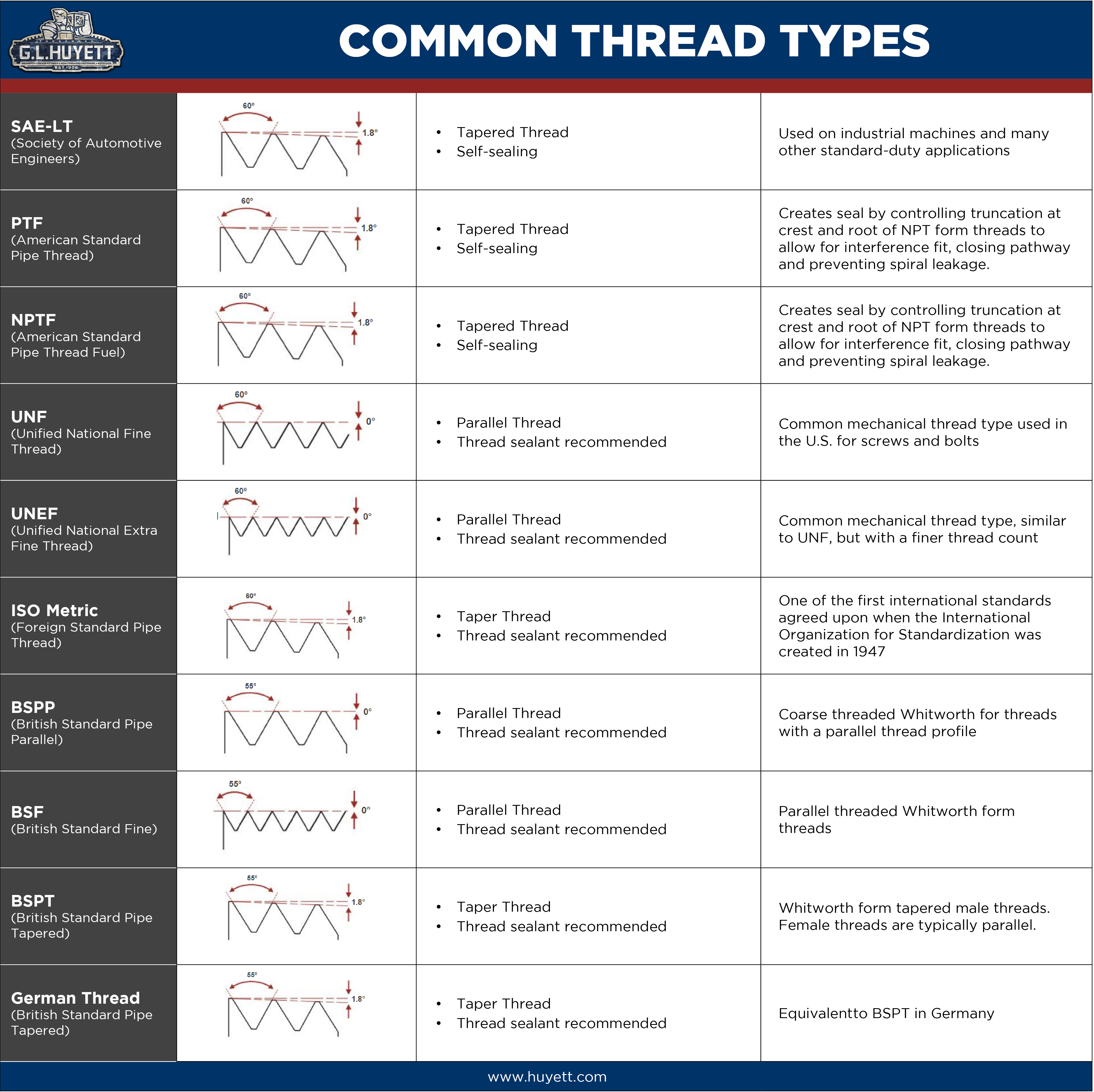

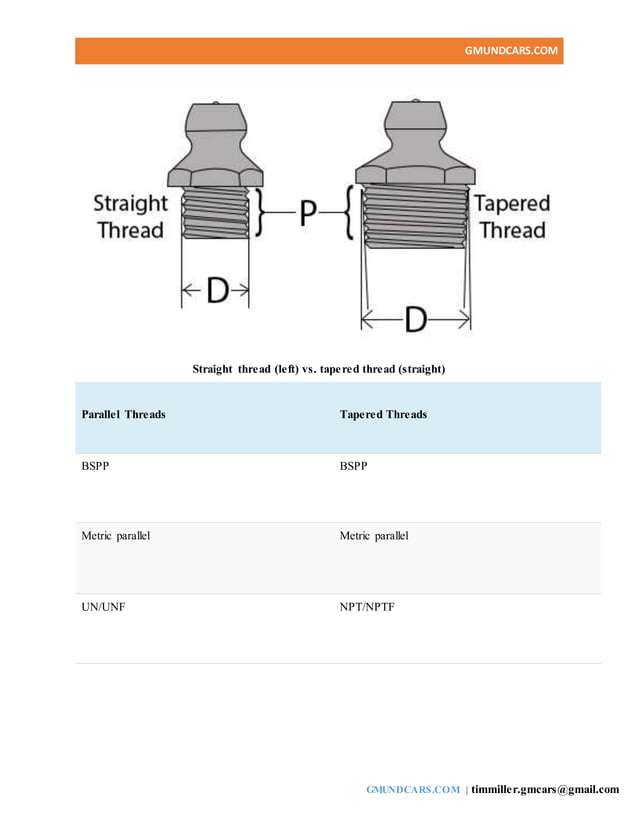

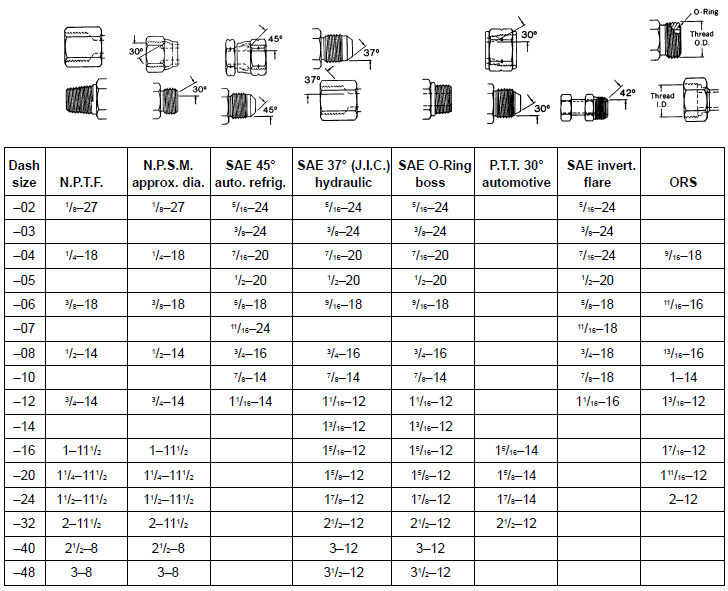

Grease Fitting Thread Size Chart - The exceptions are male and female pipe threads. Below are our most common metric thread fittings. Using the wrong size can lead to insufficient lubrication and ultimately damage your equipment. Web instructions for determining the correct grease fitting size for a new grease fitting install: Place the gauge on the threads until the fit is snug. » lubrication / grease fittings. *please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and. They come in various types, sizes and thread identifications. Web the most common size is 1/8″ npt, but there are other sizes available as well. Nominal pipe thread size can be found in corresponding row in column ii. There are two oil fitting threads that are very commonly use. Measure outside diameter of thread at b. Some fittings are also available in 303 stainless & 316 stainless. Keep a variety of grease fitting shapes, styles, and sizes on hand. *please note, this catalog is 126 pages so the file may take a minute or two to download depending. Sae‑lt (society of automotive engineers) threads possess sae pipe thread dimension of 1/4‑28 taper. Parker’s hlb remote grease hose makes it easy to properly perform quick and effective preventive maintenance on all types of industrial, mobile, and transportation equipment. Web it’s easy to determine that grease fittings thread you have at taking thre separate metering and finding your weave on. Thread these fittings into motors, bearings, engine blocks, and other machinery to create a lubrication point. Web in our last blog post we boiled grease fitting sizes down to three critical dimensions (thread size, overall height, and hex) for the purpose of gaining a fundamental understanding of grease fitting sizes and how to determine the right size grease fitting for. To view the product please click the product code. Measure the amount of space allocated for grease fitting height once installed and combine with dimension b to determine overall height (dimension a) determine the. There are two oil fitting threads that are very commonly use. Parker’s hlb remote grease hose makes it easy to properly perform quick and effective preventive. A zerk is used to lubricate mechanical parts which require grease. The first step in determining a grease fitting’s thread is to determine if the thread is straight or tapered. Find figure nearest this dimension in column i of the chart. Web the most common size is 1/8″ npt, but there are other sizes available as well. The thread fittings. The exceptions are male and female pipe threads. Hex size across the flats. Web the grease fitting thread identifier will quickly and easily identify thread patterns for the 24 most common standard, british and metric grease fittings (zerks). The thread fittings are commonly used in the bspp, bspt, metric parallel, metric tapered, npt/nptf, and un/unf. Web use a thread pitch. Grease fittings, also known as zerk fittings, are metal fittings for mechanical systems so that they can feed lubricants into various bearings using a grease gun with medium to high pressure. They come in various types, sizes and thread identifications. Using thread forming fittings eliminates costs associated with tapping methods and forms stronger, cold worked threads in the process. Web. There are two oil fitting threads that are very commonly use. *please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and. Using thread forming fittings eliminates costs associated with tapping methods and forms stronger, cold worked threads in the process. Place the gauge on the threads. Web sae products technical data page includes a grease fitting cross reference chart, lubrication fittings symbols, grease fitting installation, grease fitting information, and links and information on grease fittings, zerk fittings,grease zerk, alemite, and retaining rings. Grease fittings, also known as zerk fittings, are metal fittings for mechanical systems so that they can feed lubricants into various bearings using a. Web lubrication fittings how to determine pipe thread sizes step 1: Measure outside diameter of thread at b. Some fittings are also available in 303 stainless & 316 stainless. Measure the amount of space allocated for grease fitting height once installed and combine with dimension b to determine overall height (dimension a) determine the. And first stepping by determining a. Nominal pipe thread size can be found in corresponding row in column ii. Using thread forming fittings eliminates costs associated with tapping methods and forms stronger, cold worked threads in the process. Web the grease fitting thread identifier will quickly and easily identify thread patterns for the 24 most common standard, british and metric grease fittings (zerks). The first step in determining a grease fitting’s thread is to determine if the thread is straight or tapered. Web it’s easy to determine that grease fittings thread you have at taking thre separate metering and finding your weave on aforementioned chart below. Web download a pdf copy of our complete catalog this catalog includes every fitting on our website. Web fitting thread size comparison chart. To view the product please click the product code. Web in our last blog post we boiled grease fitting sizes down to three critical dimensions (thread size, overall height, and hex) for the purpose of gaining a fundamental understanding of grease fitting sizes and how to determine the right size grease fitting for your application. Use a female thread gauge to determine the thread length (dimension b) required; Web it’s easy to determine which grease fitting thread you have by taking three separate measurements and finding your thread on the chart below. Web thread forming grease fittings, or spin drive fittings, feature hardened threads for installation into thin, unthreaded holes. These lines connect grease port locations to a convenient service access panel where grease can be manually distributed throughout the machine. Match your measurements with the tables in this guide. A zerk is used to lubricate mechanical parts which require grease. Web see the chart below to identify your grease fitting thread.

Grease Fitting Thread Size Chart Printable Templates Free

Grease Nipple, Lubricator Series, Grease Fitting, Standard Tip (G Screw

Hexagonal Grease Nipples waliandsons

Grease Fitting Threads G.L. Huyett

AZ Guide To Grease Fitting Types, Sizes & Thread Identification PDF

Grease Fitting Sizes Chart

Fitting Thread Size Chart

13 Grease Fitting Assortmentt A & I Fasteners & Supply

Grease Fittings

ZELCAN 230pc SAE & Metric Grease Fittings Kit, Hydraulic Grease Zerk

Place The Gauge On The Threads Until The Fit Is Snug.

Below Are Our Most Common Metric Thread Fittings.

Parker’s Hlb Remote Grease Hose Makes It Easy To Properly Perform Quick And Effective Preventive Maintenance On All Types Of Industrial, Mobile, And Transportation Equipment.

Measure Outside Diameter Of Large Portion Of Thread At A.

Related Post: