Glulam Beam Weight Chart

Glulam Beam Weight Chart - Web glued laminated beam design tables glued laminated beams (glulams) are used in a wide range of applications in both commercial and residential construction. Smart, quick, easy timber beam calculations in just minutes. Web the values are based on the design properties listed in ews y117 and are in addition to the beam weight (assumed 35 pcf). If you’re looking for a different section or shape try the search feature or one of the below resources: These recommendations apply to glulam beams bearing. Web boise glulam® stock beams are available through our trusted distributors, located strategically throughout the country. Glulam beams bearing the apa ews trademark. Charts provide the weight per linear foot for various dimensions of glulam and lvl beams. Web formula and example. The following formula is used to calculate the glulam weight. Glulam beams are engineered wood products made by bonding together several layers of lumber to create a stronger and more versatile structural element commonly used in construction. 3 ⅛″ to 14 ¼″. Web beam design tables glued laminated beams (glulams) are used in a wide range of applications in both commercial and residen‑ tial construction. The tables in this publication. Web the above table of glulam sizes offers a detailed beam sizes chart for engineers to easily scroll and find what they’re looking for. Ask one of our engineers. Weight = length * width * height * density. Web calculate weight of glulam or lvl beams with our calculators. Frequently asked questions about glulam beams. Glulam beams are engineered wood products made by bonding together several layers of lumber to create a stronger and more versatile structural element commonly used in construction. 3 ⅛″ to 14 ¼″. Glulam beams bearing the apa ews trademark. The length of the glulam beam (in meters) width: If you’re looking for a different section or shape try the search. The mark appears only on. These recommendations apply to glulam beams bearing. Web a glulam weight calculator is a tool used to estimate the weight of a glulam (glued laminated timber) beam based on its dimensions. Web glued laminated beam design tables glued laminated beams (glulams) are used in a wide range of applications in both commercial and residential construction.. The tables in this engineered wood systems data file provide recommended preliminary design loads for two of the most common glulam beam applications: Web a table of glulam strength grades for varying load conditions. Web to calculate the weight of a glulam beam, the formula is as follows: These recommendations apply to glulam beams bearing. Tabulated values are pounds per. If you’re looking for a different section or shape try the search feature or one of the below resources: \ (glw\) is the glulam weight in pounds (\ (lbs\)), \ (l\) is the glulam length in feet (\ (ft\)), \ (w\) is the width in feet (\ (ft\)), \ (t\) is the thickness in feet (\ (ft\)). Web beam design. The following formula is used to calculate the glulam weight. Web the values are based on the design properties listed in ews y117 and are in addition to the beam weight (assumed 35 pcf). For preliminary design use only. Glulam beams are engineered wood products made by bonding together several layers of lumber to create a stronger and more versatile. Our beams are manufactured in widths of 31⁄8, 31⁄2, 51⁄8, 51⁄2, 63⁄4, and 83⁄4, with depths ranging from 6 to 24 and lengths up to 66 feet, with or without camber. The mark appears only on. Most stock beams are available with either a small amount of camber (5000' radius) or no camber, depending on market demands. Web formula and. Weight = length * width * height * density. Calculate glulam beam spans and sizes quickly and easily. Web to view a full list of boise glulam® beams and to obtain additional technical information, please refer to the boise glulam® beam specifier guide. \ (glw\) is the glulam weight in pounds (\ (lbs\)), \ (l\) is the glulam length in. The tables in this publication provide recommended preliminary design loads for two of the most common glulam beam applications: The height or thickness of the glulam beam (in meters) Web stock beams, manufactured in common dimensions, are cut to length when the beam is ordered from a distributor or dealer. The tables in this data file provide recommended preliminary design. Smart, quick, easy timber beam calculations in just minutes. 3 ⅛″ to 14 ¼″. Web section properties and capacities and allowable loads for simple span glulam beams Ask one of our engineers. Web enter the glulam length (ft), the width (ft), and the thickness (ft) into the glulam weight calculator. The following formula is used to calculate the glulam weight. Web boise glulam® stock beams are available through our trusted distributors, located strategically throughout the country. The height or thickness of the glulam beam (in meters) The tables in this data file provide recommended preliminary design loads for two of the most common glulam beam applications: Web the values are based on the design properties listed in ews y117 and are in addition to the beam weight (assumed 35 pcf). The calculator will evaluate the glulam weight. Calculate glulam beam spans and sizes quickly and easily. Web formula and example. The mark appears only on. Web beam weight is assumed to be 35 pcf. Tabulated values are pounds per lineal foot.

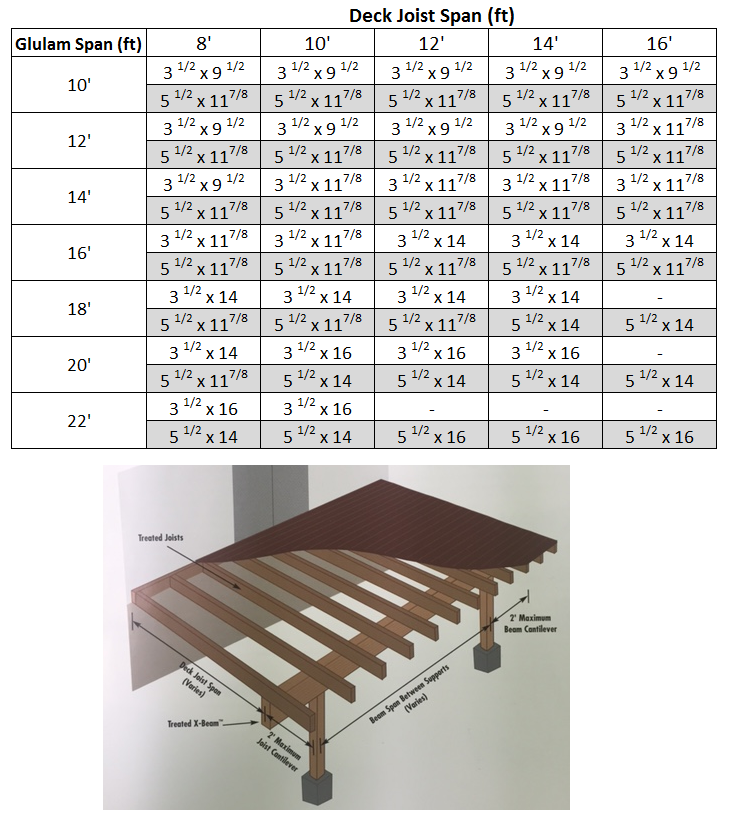

Laminated Wood Beams Span Tables

Glulam Span Chart For Beams

Glulam Beam Sizes Chart

Glulam Beam Weight Chart

Glulam Beams

Glulam Beam Span Table Us

Glulam Beams Span Chart

Glulam Timber Beam Sizes The Best Picture Of Beam

Information of glulam beams. Download Table

Glulam Beam Sizes Chart

Web Lued Laminated Beams (Glulams) Are Used In A Wide Range Of Applications In Both Commercial And Residential Construction.

Web Glued Laminated Beam Design Tables Glued Laminated Beams (Glulams) Are Used In A Wide Range Of Applications In Both Commercial And Residential Construction.

Charts Provide The Weight Per Linear Foot For Various Dimensions Of Glulam And Lvl Beams.

Glulam Beams Are Engineered Wood Products Made By Bonding Together Several Layers Of Lumber To Create A Stronger And More Versatile Structural Element Commonly Used In Construction.

Related Post: