Gel Coat Mixing Chart

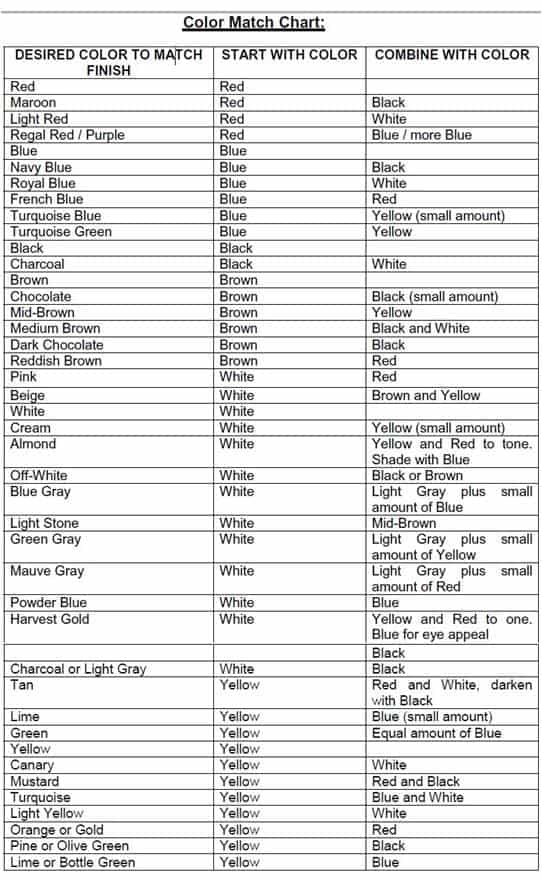

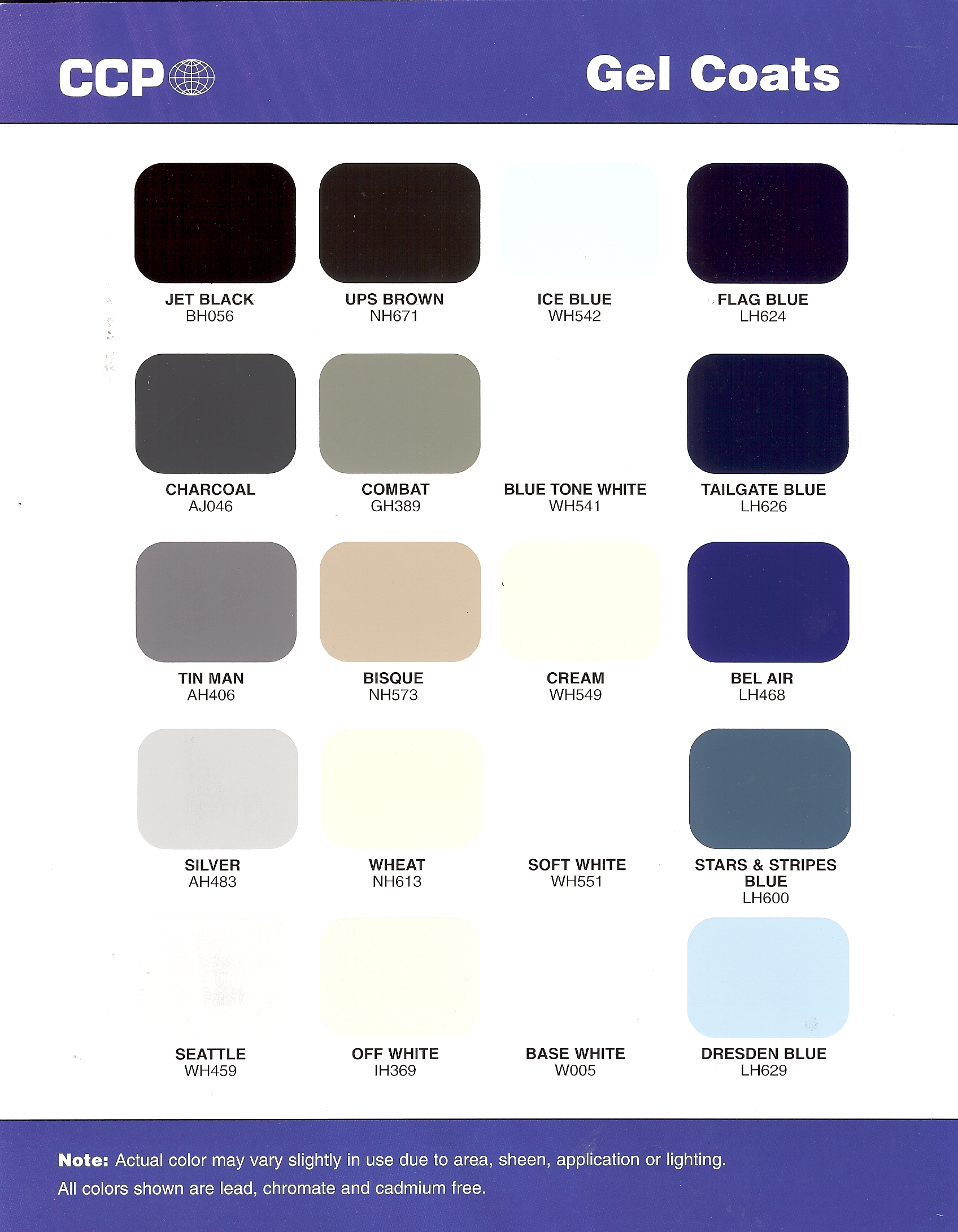

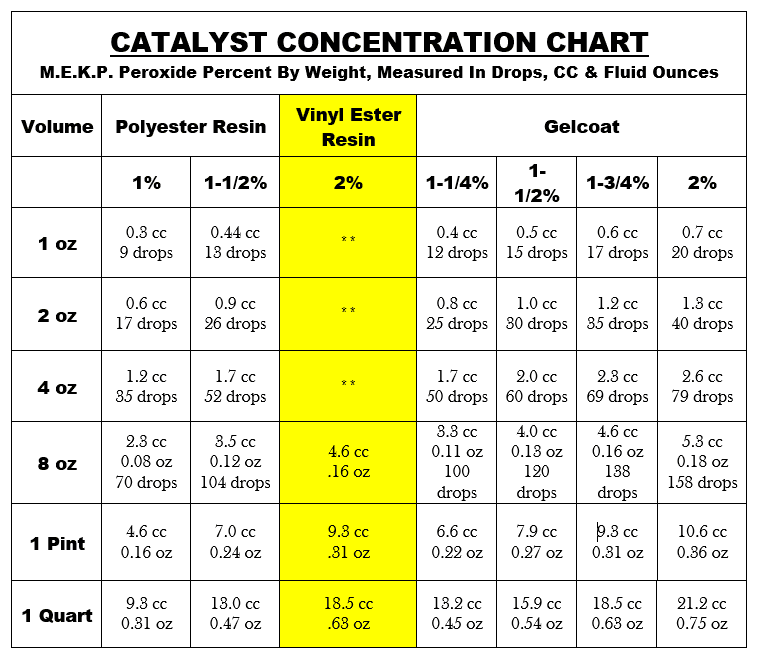

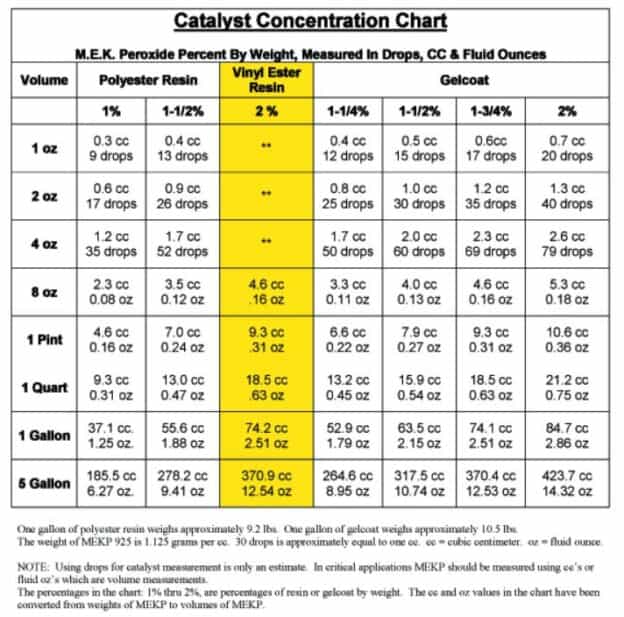

Gel Coat Mixing Chart - Catalyzation over 3%, “a hot mix” will affect gelcoat color stability. As with the previous repair, the damage is tidied with a blade, cleaned with acetone, and the area around it masked off. Web how to apply gel coat. Incomplete cure will result in poor durability of the gelcoat. Available in neutral, white, black, light gray, and moon dust. A heat gun is recommended. As the drum level goes down over time, the mixer speed needs to be It is not effective and only serves as a potential for water or oil contamination. Web the 54x series gelcoat are formulated with a particular mix of polyester resins, for use in applications where sun exposure and weather conditions are a factor. Web catalyst large quantity chart catalyst concentration resin quantity quart gallon 5 gallon 1/2% 1/16 oz 2/3 oz 3 1/3 oz 3/4% 1/4 oz 1 oz 5 oz 1% 1/3 oz 1 1/3 oz 6 2/3 oz 1 1/2% 1/2 oz 2 oz 10 oz catalyst small quantity chart catalystconcentration resin quantity30 drops = 1 cc 2 oz 4 oz 8 oz 12 oz 16 oz 1/2 % 9. Remove rails, cleats, louvers, snaps, striping tape, etc. Mix thoroughly to ensure that all gel coat is properly catalyzed. Part # mc100 (mixing cup) note: Web how to apply gel coat. Available in neutral, white, black, light gray, and moon dust. It is not effective and only serves as a potential for water or oil contamination. The ideal mixer speed will change as the volume of the drum decreases. Available in neutral, white, black, light gray, and moon dust. Web below are two free mekp calculators and a mekp chart to simplify the process of determining the proper ratio of resin. The first thing you want to do is take a good look at the surface you want the gel coat applied to. Heat may be applied to accelerate cure time. A heat gun is recommended. Part # mc100 (mixing cup) note: Notice the needle size of the orifice on the dropper tip of the dropper bottle. Surface temperature must be a least 50°f (10°c) above dew point. Available in neutral, white, black, light gray, and moon dust. Web the 54x series gelcoat are formulated with a particular mix of polyester resins, for use in applications where sun exposure and weather conditions are a factor. Incomplete cure will result in poor durability of the gelcoat. Web mek,. Below are two free mekp calculators and a mekp chart to simplify the process of determining the proper ratio of resin to catalyst or gelcoat to catalyst. A heat gun is recommended. Web directions for polyester hardener. Web as a general rule, coatings should be applied in good weather when air and surface temperatures are above 50°f (10°c) for most. They are suitable for boats, truck cabs, water slides and environments with humidity and direct sun exposure. Unlike mixing paints, colour matching gelcoats with pigments can be tricky, but it is possible to get a close match. Our gelcoat color match chart is the perfect solution for any boat repair project. Web as a general rule, coatings should be applied. Air bubbling should not be used for mixing. Mekp (methyl ethyl ketone peroxide), included colors: A heat gun is recommended. Web our gelcoat color matching chart is designed to assist you in finding the ideal gelcoat color for your boat. The ideal mixer speed will change as the volume of the drum decreases. We offer a wide selection of colors that cater to various boat manufacturers, ensuring that you can find the. Notice the needle size of the orifice on the dropper tip of the dropper bottle. Web catalyst large quantity chart catalyst concentration resin quantity quart gallon 5 gallon 1/2% 1/16 oz 2/3 oz 3 1/3 oz 3/4% 1/4 oz 1 oz. If the surface is already coated with gel coat, or if the. Part # mc100 (mixing cup) note: Air bubbling should not be used for mixing. The ratio is approximately one ounce of hardener per gallon of resin. Due to the lower monomer content for low emissions, we suggest catalyzing the le gel coat at 2% depending on ambient temperatures. Our gelcoat color match chart is the perfect solution for any boat repair project. For faster cure times, a “maximum catalyst” of 3% is recommended; Air bubbling should not be used for mixing. Gelcoats are based on a thermoset resin that requires an initiator and proper temperatures to cure thoroughly. Below are two free mekp calculators and a mekp chart. Web the gel coat should be mixing to the sides and bottom of the container with the least amount of turbulence possible. Heat may be applied to accelerate cure time. Due to the lower monomer content for low emissions, we suggest catalyzing the le gel coat at 2% depending on ambient temperatures. Most gelcoat colours have a code commonly known as a ral or bs number. Incomplete cure will result in poor durability of the gelcoat. Notice the needle size of the orifice on the dropper tip of the dropper bottle. Air bubbling should not be used for mixing. Remove rails, cleats, louvers, snaps, striping tape, etc. Web mixing cup will give exact measurements for larger volumes in cc and ounce increments. We offer a wide selection of colors that cater to various boat manufacturers, ensuring that you can find the. Surface temperature must be a least 50°f (10°c) above dew point. Our gelcoat color match chart is the perfect solution for any boat repair project. Web directions for polyester hardener. As with the previous repair, the damage is tidied with a blade, cleaned with acetone, and the area around it masked off. Below are two free mekp calculators and a mekp chart to simplify the process of determining the proper ratio of resin to catalyst or gelcoat to catalyst. Web the ideal range is 1.8% @ 77°f (approximately 12 drops per ounce of gelcoat.) if the gelcoat does not get enough catalyst it will not “kick” or begin to harden.Fiberlay Gelcoat Color Chart PDF

Gelcoat Color Match Chart

Stuart Marine Corp. Gel Coat Colors

How to Apply Gelcoat by Brush and Roller How to Articles Bottom

.jpeg/:/cr=t:0%25,l:0%25,w:100%25,h:100%25)

Spectrum Gelcoat Color Chart

Gel Coat Coverage Chart A Visual Reference of Charts Chart Master

Gel Coat Repair Series Matching Gel Coat Colors Fiberglass Warehouse

How to Apply Gelcoat Easy Gelcoat Application

How To

How to Apply Gelcoat Easy Gelcoat Application

Mekp (Methyl Ethyl Ketone Peroxide), Included Colors:

Web Mek, Short For Mekp, Is The “Hardener” Or Catalyst For Polyester Resin And Vinylester Resin Systems Including Isothalic And Gelcoat.

Web Correct Application Of Gelcoat Is Critical To Get The Optimum Performance From It.

Duct Tape Off Adjacent Gunwale Molding, And Deck Fittings You Are Unable To.

Related Post: