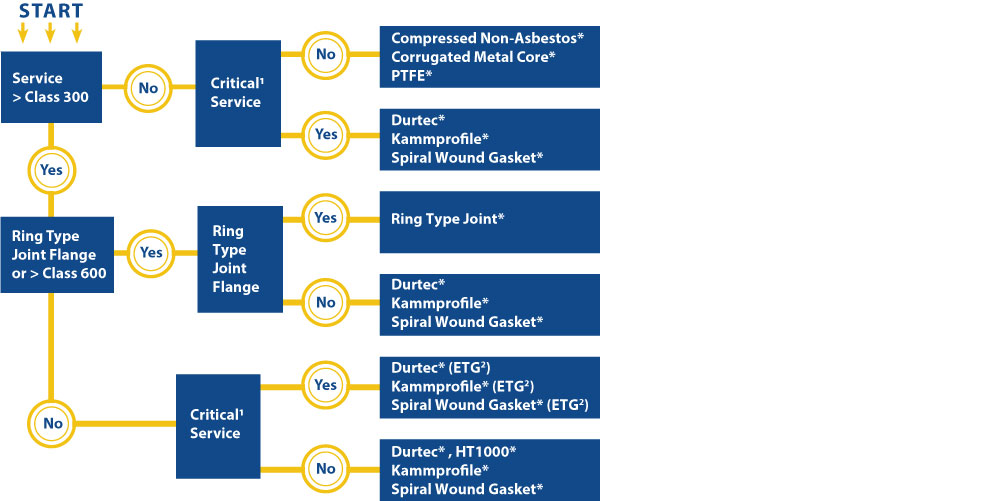

Gasket Material Selection Chart

Gasket Material Selection Chart - Compressed gaskets chemical resistance chart. As the engineer responsible for ensuring the performance and safety of sealing components, there can be quite a lot of pressure riding on making the proper material selection for a specific application. Lamons’ various locations feature leading technology and state of the art manufacturing facilities capable of producing engineered products to custom specifications serving the refining, chemical, power generation, offshore, subsea, petrochemical (upstream and When system operating temperatures approach a Web selection of gasket materials and fastener stock ready for immediate delivery. Web gasketing selection & tamps temperature in most selection processes, the temperature of the fluid at the gasketed joint should be considered first. Web the higher he operating temperature, the more care needs to be taken with the gasket material selection. Web the guide will assist you in gasket material selection, gasket design and gasket application. + resistant to fuels, oil, solvents and refrigerants. Evaluating fluid temperature, corrosive properties, and pressure. There are many materials that cover similar temperature ranges so more elements have to be taken into consideration. The huge variety of materials, shapes and sizes offers an infinite scope of application possibilities. Web application is essential in the proper selection of a gasket. There are a wide range of choices when considering materials while designing a seal. Different coeficients. Web an engineer's guide to material selection for gaskets. Both are used in gasket materials, and in somecases blended. Lamons’ various locations feature leading technology and state of the art manufacturing facilities capable of producing engineered products to custom specifications serving the refining, chemical, power generation, offshore, subsea, petrochemical (upstream and We offer both hard and soft versions to fit. Web a complete gasket selection guide, learn the different types of gaskets, materials, and common uses. Gaskets are used for a wide variety of applications in every industry. + compressible with negligible lateral flow. Choose the best gasket for your needs. This is composed of thin metals and offers a seal at minimal seating tension. Amongst these three types of gasket materials neoprene, nitrile, epdm, viton, natural rubber, silicone, bonded cork, statite oil proof paper and cnaf 4324 are amongst the most popular. Web here are the various solid gasket materials available: Understanding the characteristics of various rubber types is crucial when choosing the appropriate gasket material. Selecting the right gasket design and material is. Understanding the characteristics of various rubber types is crucial when choosing the appropriate gasket material. This gives a good seal with lower seating strains due to its surface grooves. As an independent company we can source materials from all major material manufacturers. Selecting the right gasket design and material is critical to the effective operation of a reliable joint. Both. Table2 summarizes the typical fluids of each category. Offers an extensive selection of gasket materials for all temperature ranges, resistance requirements, and environmental demands. Choose the best gasket for your needs. Web selection of gasket materials and fastener stock ready for immediate delivery. As the system is pressurized and heated, the joint deforms. Web gasketing selection & tamps temperature in most selection processes, the temperature of the fluid at the gasketed joint should be considered first. Web the guide will assist you in gasket material selection, gasket design and gasket application. Web assembly of gaskets into both new and existing installations. This will reduce the number of product candidates quickly, especially as temperatures. This gives a good seal with lower seating strains due to its surface grooves. Choosing the best types of gaskets. We offer both hard and soft versions to fit your application. Search our gasket material specification sheets to find the right material for you. Web an engineer's guide to material selection for gaskets. Search our gasket material specification sheets to find the right material for you. Gaskets are used for a wide variety of applications in every industry. Web view rubber cork gaskets. Compressed gaskets chemical resistance chart. + resistant to fuels, oil, solvents and refrigerants. Shurjoint grooved couplings utilize several different gasket styles, standard, gapseal, ep (end protection) and ff (fast fit). Choosing the best types of gaskets. This will reduce the number of product candidates quickly, especially as temperatures go from 200°f (95°c) to 1,000°f (540°c). Search our gasket material specification sheets to find the right material for you. Follow this link to see. We offer both hard and soft versions to fit your application. Choosing the best types of gaskets. Amongst these three types of gasket materials neoprene, nitrile, epdm, viton, natural rubber, silicone, bonded cork, statite oil proof paper and cnaf 4324 are amongst the most popular. Web the guide will assist you in gasket material selection, gasket design and gasket application. The process temperature and pressure. Understanding the characteristics of various rubber types is crucial when choosing the appropriate gasket material. As an independent company we can source materials from all major material manufacturers. Web gasket material selection guide. This will reduce the number of product candidates quickly, especially as temperatures go from 200°f (95°c) to 1,000°f (540°c). There are 10 fluid categories as listed below. Web a complete gasket selection guide, learn the different types of gaskets, materials, and common uses. Lamons’ various locations feature leading technology and state of the art manufacturing facilities capable of producing engineered products to custom specifications serving the refining, chemical, power generation, offshore, subsea, petrochemical (upstream and Table2 summarizes the typical fluids of each category. + resistant to fuels, oil, solvents and refrigerants. Web proper gasket selection is essential for the optimum performance of. Choose the best gasket for your needs.

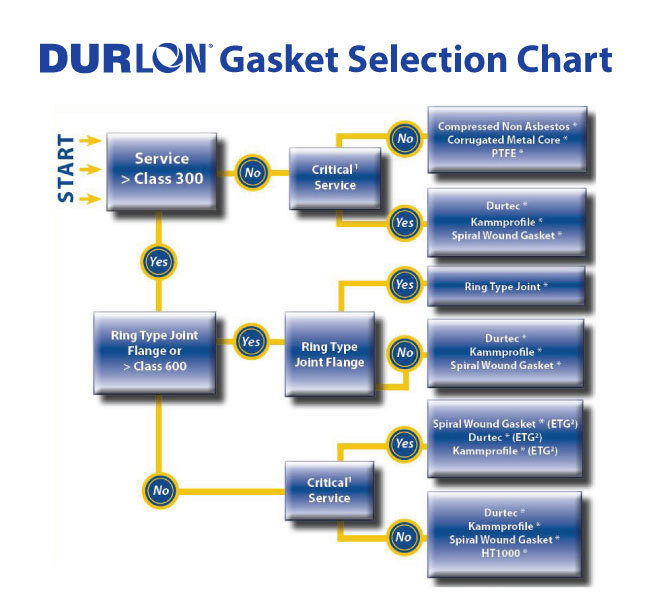

Gasket Selection Chart Triangle Fluid Controls Ltd.

Gasket Material Selection Tools Triangle Fluid Controls Ltd.

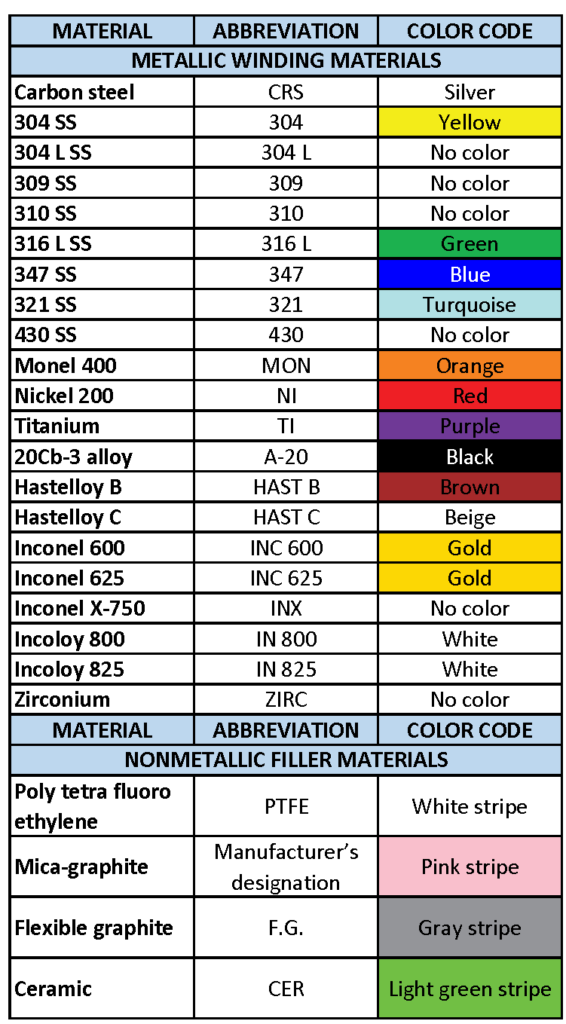

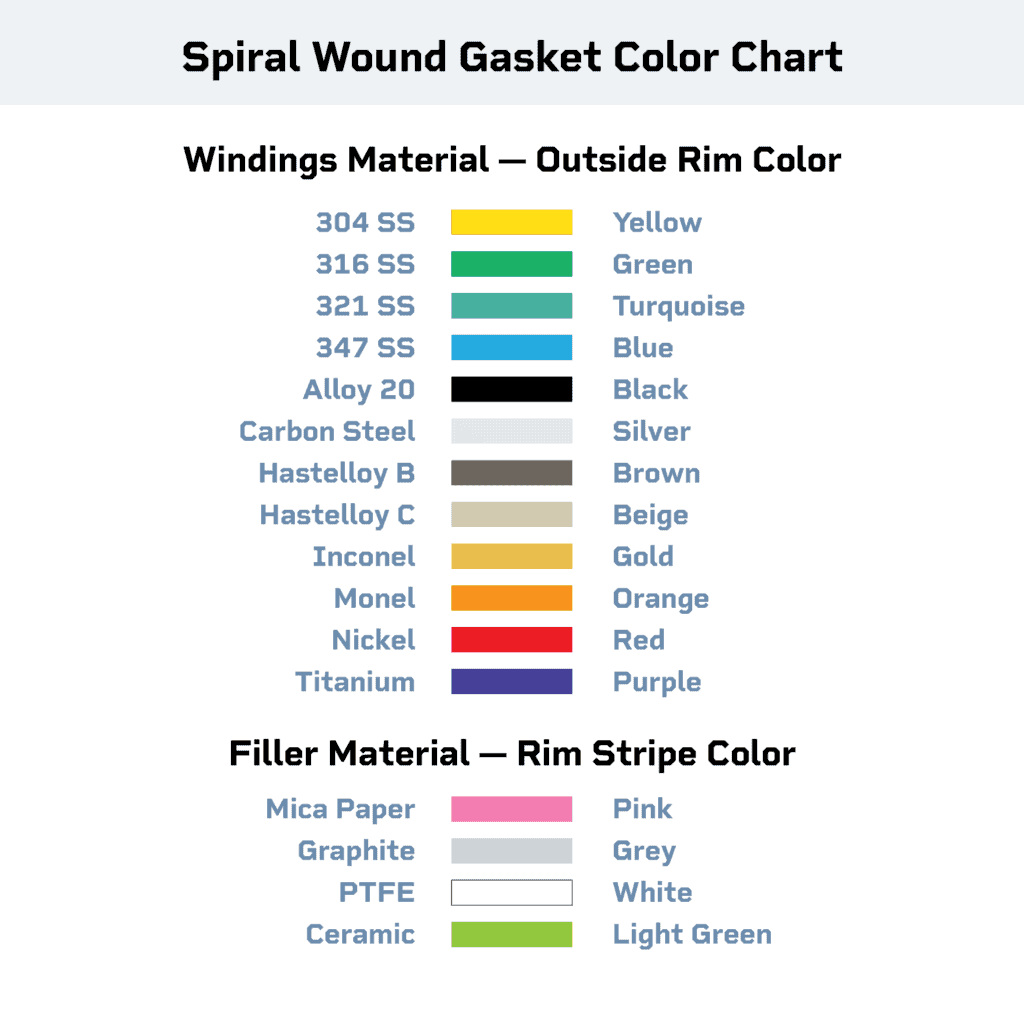

Learn About Spiral Wound Gasket And Color Code

Gasket Selection

TECHNORTH Rustenburg Klinger Gasket Selection

Gasket Selection Chart A Visual Reference of Charts Chart Master

Gasket Selection Chart A Visual Reference of Charts Chart Master

Gasket Types in Oil and Gas, Explained Hex Technology (2022)

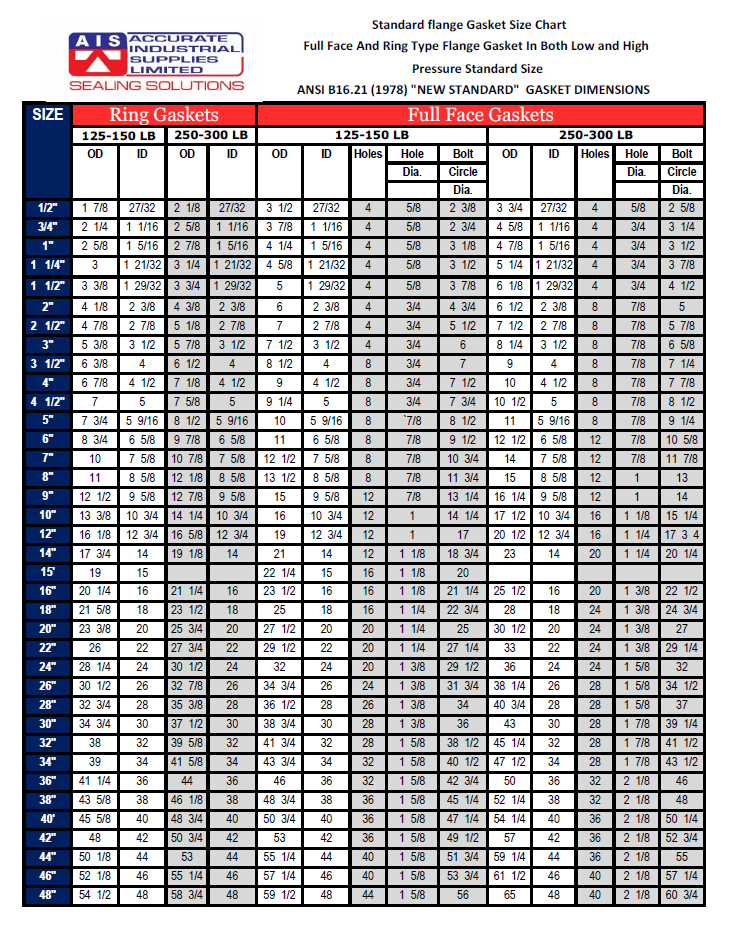

GASKET SIZING CHART Accurate Industrial Supplies

Gasket Chart

This Gives A Good Seal With Lower Seating Strains Due To Its Surface Grooves.

There Are A Wide Range Of Choices When Considering Materials While Designing A Seal.

Follow This Link To See Our Jointing Selection Guide.

As The Engineer Responsible For Ensuring The Performance And Safety Of Sealing Components, There Can Be Quite A Lot Of Pressure Riding On Making The Proper Material Selection For A Specific Application.

Related Post: