Galvanic Action Chart

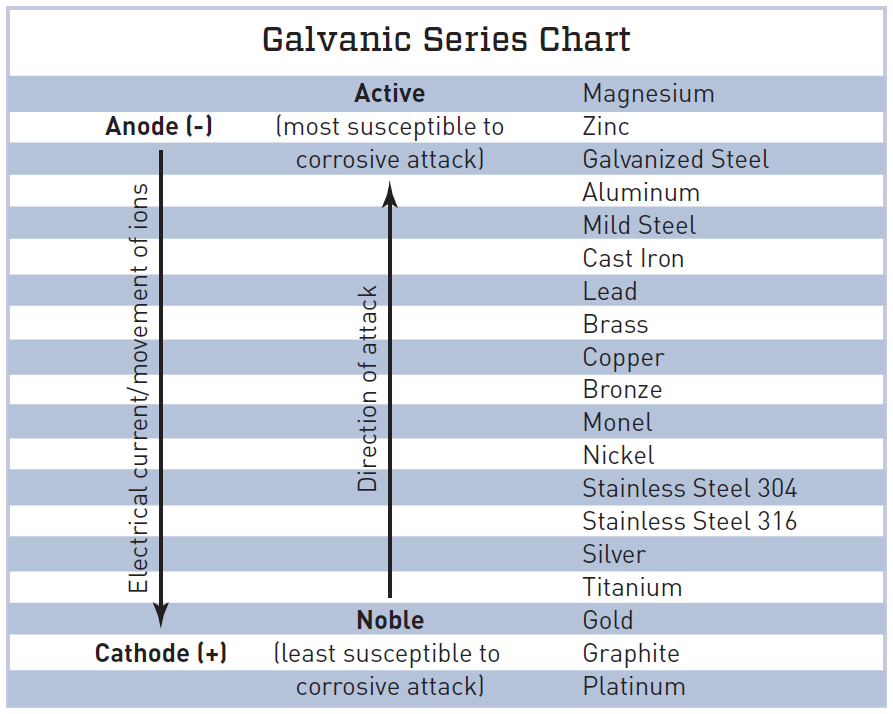

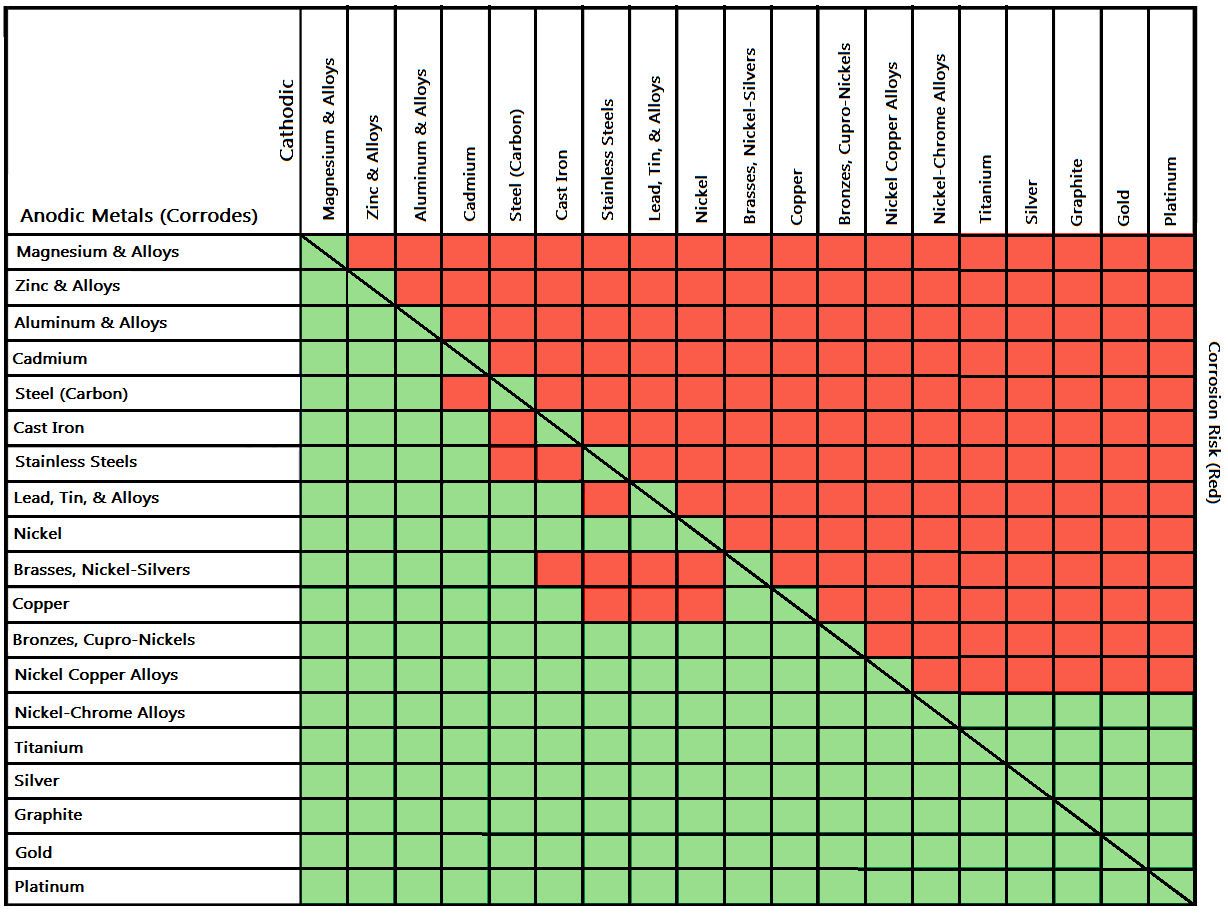

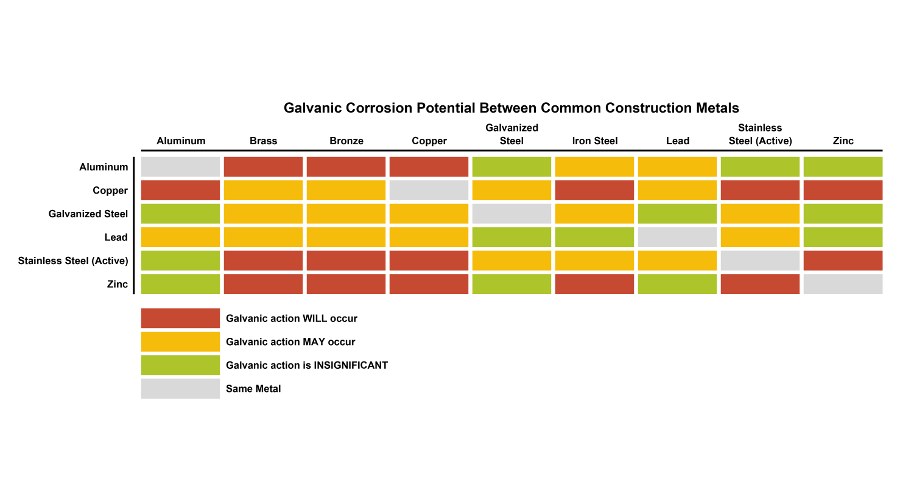

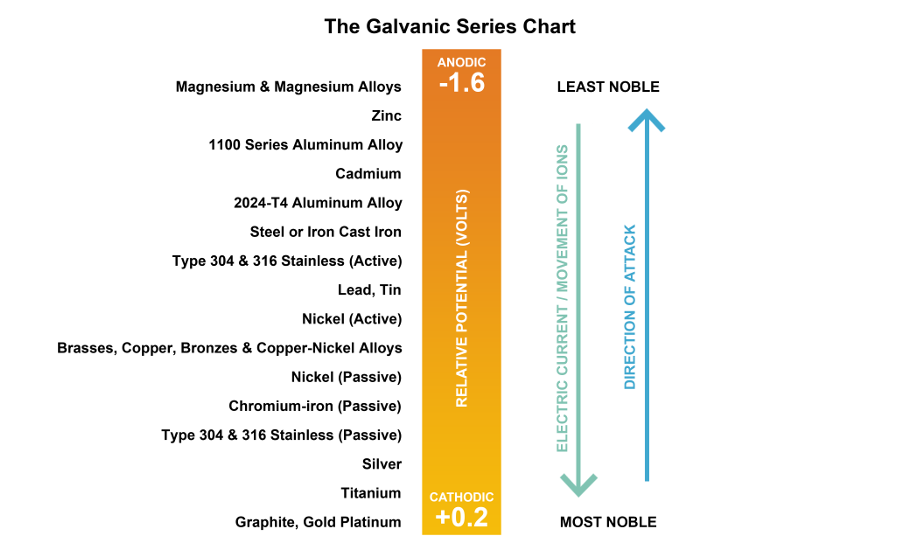

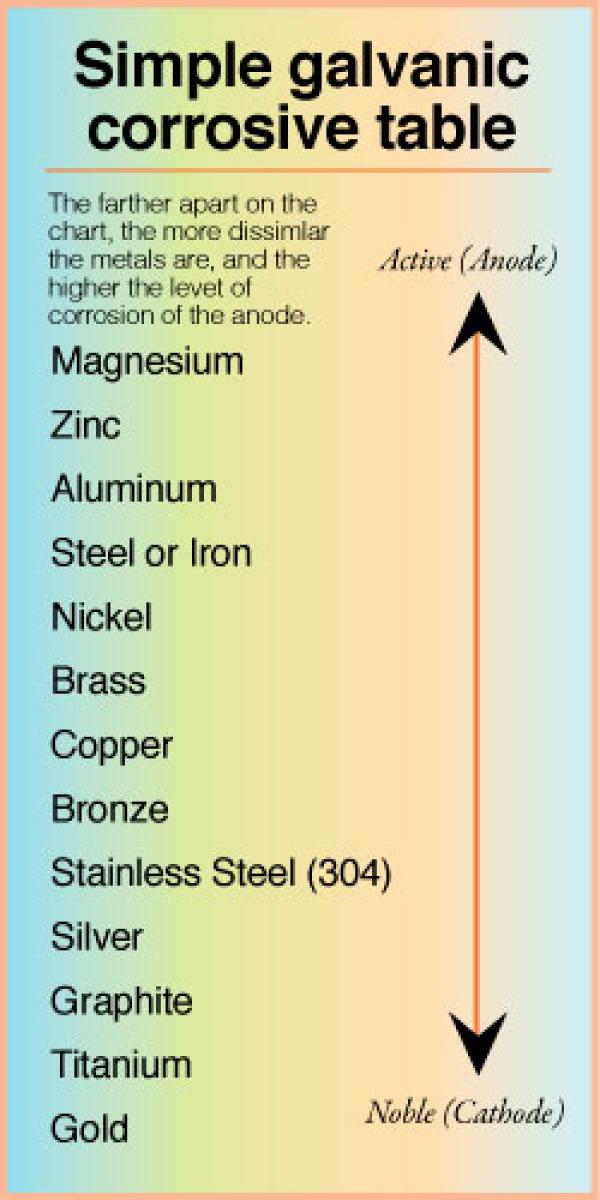

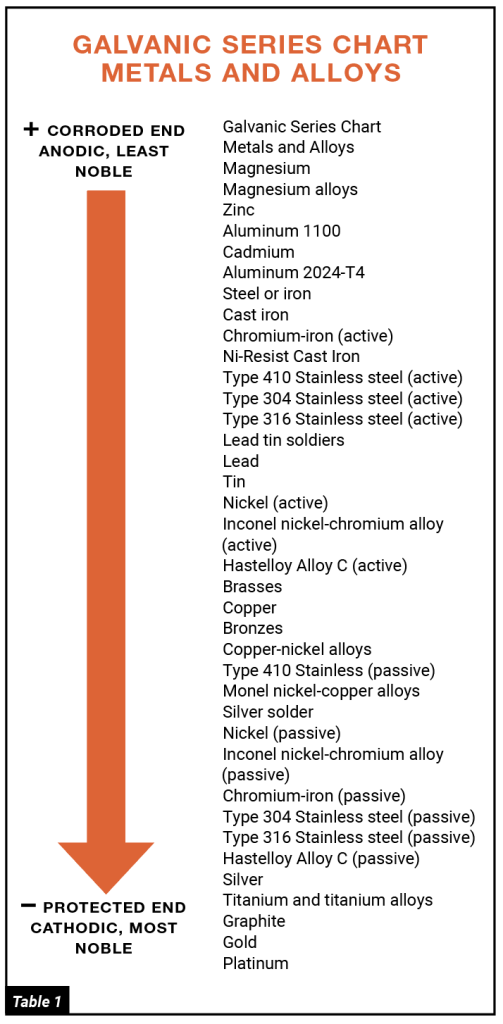

Galvanic Action Chart - Yet in today’s construction world it can be easy for a contractor to mix the wrong type of fastener with the wrong metal. In this respect, one should understand how to read the following chart which lists all metals. When dissimilar metals are used together in the presence of an electrolyte, separate them with a dielectric material such as insulation, paint or similar surface coating. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal. What is the galvanic series? Select materials that are as close together as possible in the galvanic series chart. This can help you in the selection of the best materials for your application where galvanic corrosion is a concern. Types of galvanic corrosion in different metals and their alloys. First there must be two electrochemically dissimilar metals present. You can also learn more about overcoming potentially compatibility issues between metals. The list begins with the more active (anodic) metal and proceeds down. Types of galvanic corrosion in different metals and their alloys. In this article, we'll look at an example to illustrate the use of the galvanic table. Select materials that are as close together as possible in the galvanic series chart. Web galvanic corrosion is a localised mechanism by. Web galvanic corrosion happens when two conductive metals (anode and cathode) are in contact and exposed to an electrolyte with a return current path. Web read on to find out about what it is and how to use it to analyse the compatibility of joining metals. Web fastened of galvanic corrosion in joint, it’s recommended to choose materials that are. Web by simply choosing metals that avoid galvanic action there will never be an issue. Web galvanic corrosion is a localised mechanism by which metals can be preferentially corroded. In certain cases one metal immediately following another may be very corrosive. Web fastened of galvanic corrosion in joint, it’s recommended to choose materials that are grouped together in the galvanic. Galvanic voltage relative to standard electrode. Simpletwig will then try to. If that’s not possible, other recommendations are: The list begins with the more active (anodic) metal and proceeds down. Select materials that are as close together as possible in the galvanic series chart. Web view our galvanic series chart, pictures, definitions, and even a mnemonic device! Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal combinations. Web by simply choosing metals that avoid galvanic action there will never be an issue. Galvanic voltages relative to gold.. Web view our galvanic series chart, pictures, definitions, and even a mnemonic device! This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal. Below is a galvanic reaction chart for dissimilar metals. Values given here are for indicative purpose only. Yet in today’s construction world. Web read on to find out about what it is and how to use it to analyse the compatibility of joining metals. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal combinations. Web fastened of galvanic corrosion in joint, it’s recommended to choose. Yet in today’s construction world it can be easy for a contractor to mix the wrong type of fastener with the wrong metal. Types of galvanic corrosion in different metals and their alloys. The metallic phases, compounds, dilution or enrichment regions of component elements, and oxidation films in the alloy showing different electrode potentials may also be galvanically with the. Web galvanic corrosion happens when two conductive metals (anode and cathode) are in contact and exposed to an electrolyte with a return current path. Web by simply choosing metals that avoid galvanic action there will never be an issue. Web galvanic corrosion is a localised mechanism by which metals can be preferentially corroded. In certain cases one metal immediately following. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal. The below galvanic corrion chart or anodic index table shows anodic index for different materials. Web below is a galvanic reaction chart for dissimilar metals. There are three conditions that must exist for galvanic corrosion. Yet in today’s construction world it can be easy for a contractor to mix the wrong type of fastener with the wrong metal. Simpletwig will then try to. Types of galvanic corrosion in different metals and their alloys. If that’s not possible, other recommendations are: Web the galvanic action increases as the metals are farther apart in the galvanic series. Web when dissimilar metals are connected — either by simple contact or by wiring — and they are immersed in water, a current will flow which can cause galvanic corrosion. What is the galvanic series? In certain cases one metal immediately following another may be very corrosive. Web read on to find out about what it is and how to use it to analyse the compatibility of joining metals. Web galvanic corrosion is a localised mechanism by which metals can be preferentially corroded. If you're a designer working with exterior metals, you've probably heard of galvanic corrosion. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. What are the causes of galvanic corrosion? The list begins with the more active (anodic) metal and proceeds down. You can also learn more about overcoming potentially compatibility issues between metals. The below galvanic corrion chart or anodic index table shows anodic index for different materials.

Galvanic Action Corrosion Prevention Architect's Blog

Galvanic Series Chart

Galvanic Corrosion Common Questions Answered

Galvanic Corrosion Compatibility Chart

Galvanic Chart Of Metals

Galvanic Corrosion Chart Metals

Galvanic Reaction Chart All Points Fasteners

Galvanic Corrosion Chart Dissimilar Metals Video Bokep Ngentot

Galvanic Action Chart PDF

Prevent Galvanic Action Frame Building News

Web Galvanic Corrosion Happens When Two Conductive Metals (Anode And Cathode) Are In Contact And Exposed To An Electrolyte With A Return Current Path.

To Use The Chart, Align The Metal To Be Assessed (For The Risk Of Corrosion) In The Left Column With The Contact Metal Listed In The.

Web Below Is A Galvanic Reaction Chart For Dissimilar Metals.

This Chart Is Designed To Assist In Broadly Assessing The Risk Of Galvanic Corrosion Associated With A Given Metal Coming Into Contact With Another Metal.

Related Post: