Galling Resistance Chart

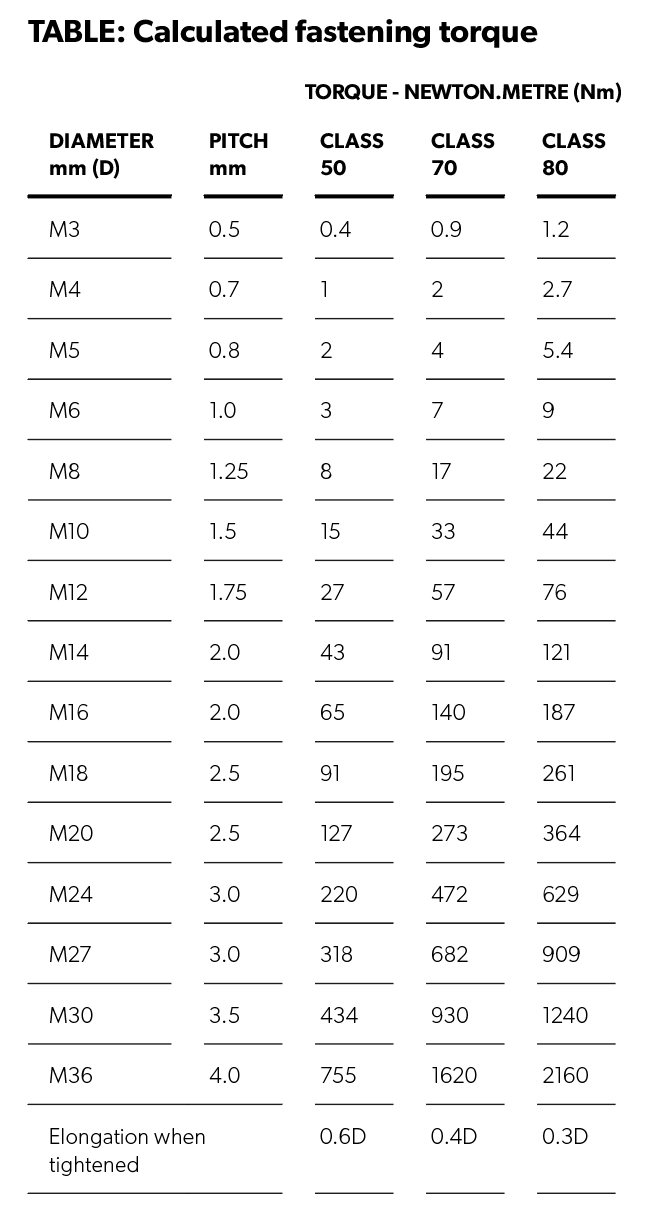

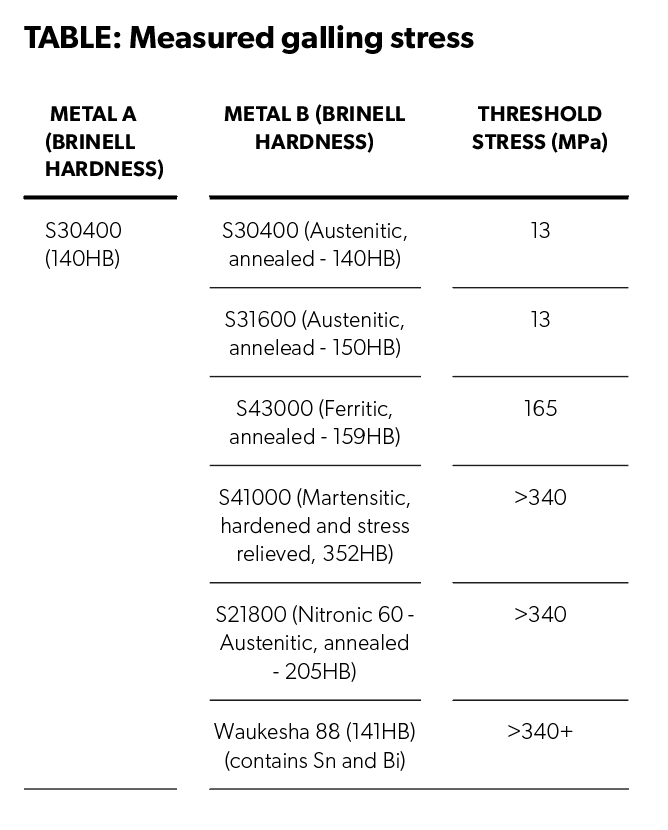

Galling Resistance Chart - Web the galling resistance chart shows how different materials behave under friction. Web review of wear and galling characteristics of stainless steel (9006) discusses design factors in assemblies where sliding contact exists between wrought. Web galling and galling resistance of stainless steels. Web the metal galling resistance chart is a representation that provides typical galling resistance characteristics for material combinations when used to rub against each other. The number immediately following the designation indicates the year of original adoption. It indicates that the galling time can be from 7 seconds to 58 seconds at 1a specific load. Galling data shows that identical metal couples usually do poorly in terms of galling. Web raw materials have been developed to reduce galling while maintaining corrosion resistance. Web table 1 compares galling characteristics of seven types of stainless steel. Web severe galling can result in the seizure of metal components. Web the main factors affecting wear and galling are: This standard is issued under the fixed designation g 98; Web severe galling can result in the seizure of metal components. Web the galling resistance chart shows how different materials behave under friction. Web galling and galling resistance of stainless steels. Web use our handy threshold galling stress chart to help you on your current project! Galling data shows that identical metal couples usually do poorly in terms of galling. Web galling and galling resistance of stainless steels. Web galling is caused by the asperities (high points) of one component puncturing the protective oxide layer of another, and then transferring material. Web severe galling can result in the seizure of metal components. Web galling stress is a good measure of wear resistance of a given material pair. Web review of wear and galling characteristics of stainless steel (9006) discusses design factors in assemblies where sliding contact exists between wrought. Web galling resistance of materials1. One of the major problems in use. Web use our handy threshold galling stress chart to help you on your current project! Austenitic stainless steels are widely used for corrosion resistant bolting. Web galling and galling resistance of stainless steels. Web table 1 compares galling characteristics of seven types of stainless steel. It indicates that the galling time can be from 7 seconds to 58 seconds at. Web galling resistance of materials1. Web the galling resistance chart shows how different materials behave under friction. One of the major problems in use is that disassembly is dificult because nuts and bolts. Web table 1 compares galling characteristics of seven types of stainless steel. Web the document is a chart that evaluates the wear and galling resistance of combinations. Web raw materials have been developed to reduce galling while maintaining corrosion resistance. Web use our handy threshold galling stress chart to help you on your current project! Austenitic and precipitation hardening stainless steels exhibit low galling resistance. Web the document is a chart that evaluates the wear and galling resistance of combinations of different material types in contact. It. This standard is issued under the fixed designation g 98; One of the major problems in use is that disassembly is dificult because nuts and bolts. Austenitic stainless steels are widely used for corrosion resistant bolting. Web soft very ductile austenitic stainless steel types tend to gall or seize where high stresses and poor lubrication are present. It highlights that. It highlights that the resistance level varies significantly across alloys. Web table 1 compares galling characteristics of seven types of stainless steel. It indicates that the galling time can be from 7 seconds to 58 seconds at 1a specific load. Web raw materials have been developed to reduce galling while maintaining corrosion resistance. Web review of wear and galling characteristics. One of the major problems in use is that disassembly is dificult because nuts and bolts. Web galling stress is a good measure of wear resistance of a given material pair. Web the main factors affecting wear and galling are: This standard is issued under the fixed designation g 98; Web galling is caused by the asperities (high points) of. Web soft very ductile austenitic stainless steel types tend to gall or seize where high stresses and poor lubrication are present. Web galling stress is a good measure of wear resistance of a given material pair. Austenitic and precipitation hardening stainless steels exhibit low galling resistance. Web severe galling can result in the seizure of metal components. Web review of. Web the document is a chart that evaluates the wear and galling resistance of combinations of different material types in contact. Web galling resistance of materials1. Design, applied load, contact area and degree of movement, lubrication, environment, material properties (surface finish,. Web soft very ductile austenitic stainless steel types tend to gall or seize where high stresses and poor lubrication are present. It rates combinations on a scale of 1 to 2 to x, with 1. Web galling stress is a good measure of wear resistance of a given material pair. Web table 1 compares galling characteristics of seven types of stainless steel. The factors affecting galling are covered, particularly. Web the metal galling resistance chart is a representation that provides typical galling resistance characteristics for material combinations when used to rub against each other. Galling data shows that identical metal couples usually do poorly in terms of galling. Web the main factors affecting wear and galling are: It indicates that the galling time can be from 7 seconds to 58 seconds at 1a specific load. Web severe galling can result in the seizure of metal components. Web review of wear and galling characteristics of stainless steel (9006) discusses design factors in assemblies where sliding contact exists between wrought. Austenitic and precipitation hardening stainless steels exhibit low galling resistance. One of the major problems in use is that disassembly is dificult because nuts and bolts.

stainless steel galling table

Galvanic Corrosion Chart Dissimilar Metals Video Bokep Ngentot

stainless steel galling table

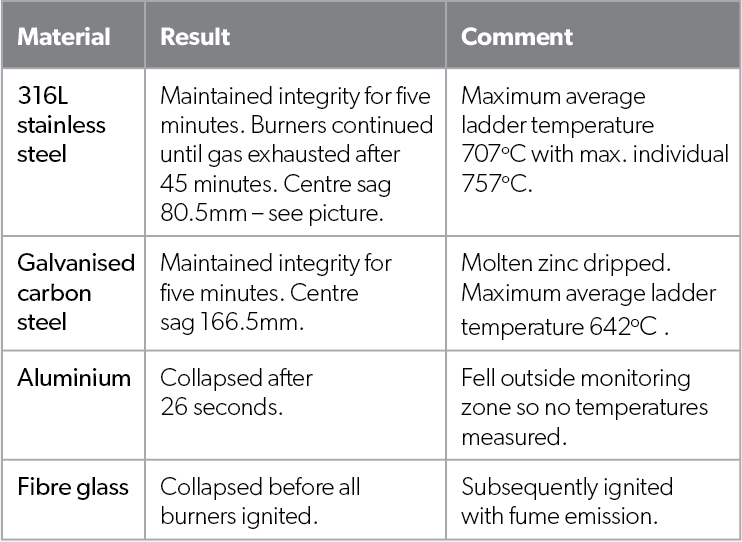

FAQ 5 Galling and its Control

Wear And Galling Resistance Chart Of Material Combinations A Visual

Wear And Galling Resistance Chart Of Material Combinations Online Shopping

FAQ 1 Galvanic/Dissimilar Metal Corrosion

Strongest Stainless steel fastener in the world 2012

stainless steel galling table

FAQ 5 Galling and its Control

Web Use Our Handy Threshold Galling Stress Chart To Help You On Your Current Project!

Web Raw Materials Have Been Developed To Reduce Galling While Maintaining Corrosion Resistance.

The Mechanism Is Briefly Described.

An Aisi Booklet Shows The Galling Resistance Of Various.

Related Post: