Flux Core Welding Settings Chart

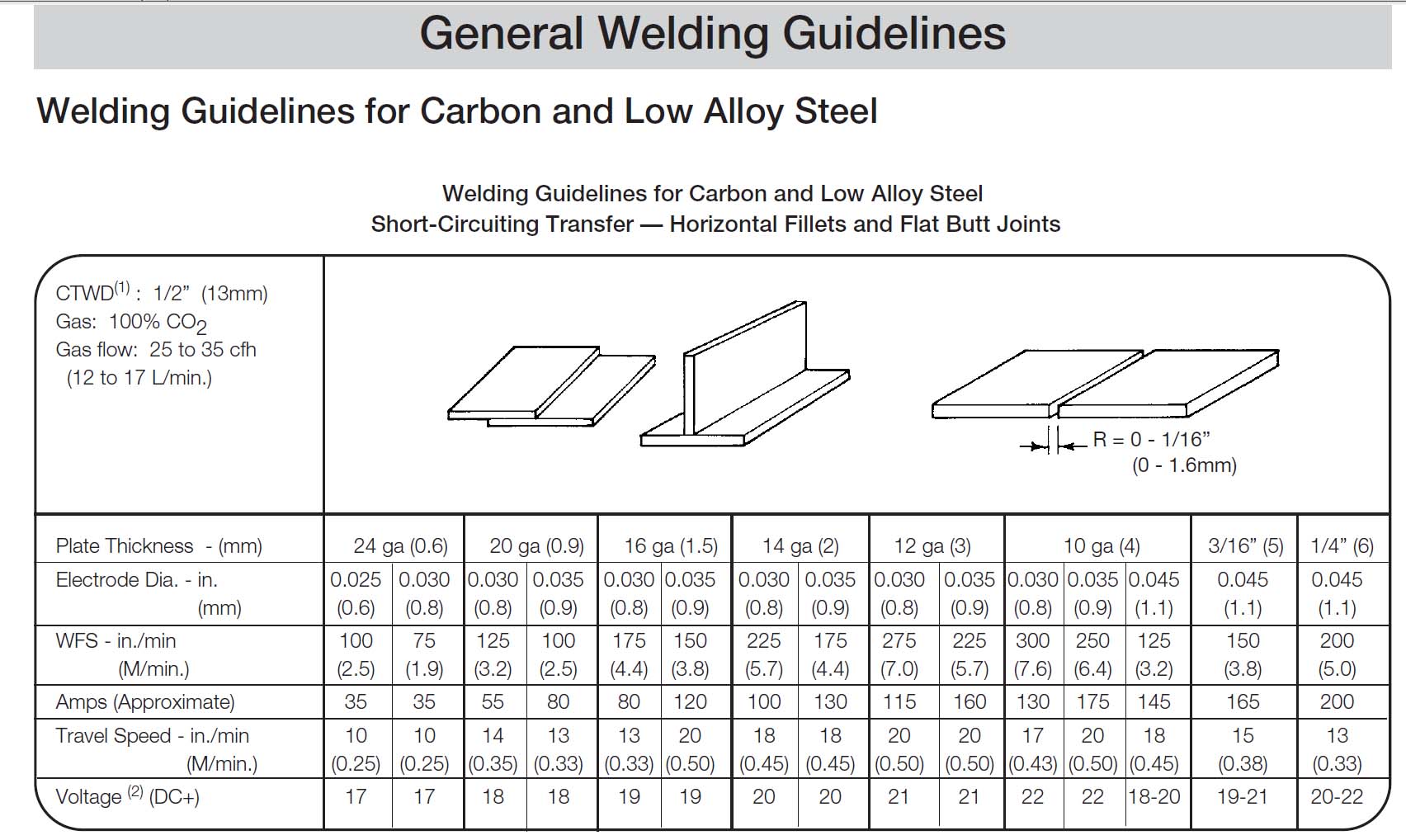

Flux Core Welding Settings Chart - Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. Web chart usage for various welding jobs. This chart is essential for achieving proper weld. But before using these values, we suggest that you have a decent understanding of your preferred metal. Refer to the chart to determine each job’s optimal wire speed and voltage settings, ensuring consistent and reliable welds. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. Here's a guide to setting it up the. Browse suggested weld parameter settings for stick welding, tig welding, mig (solid. What material are you welding? So, how many amps does it take to weld 3/8 steel? A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. There is some nuance to it. Refer to the chart to determine each job’s optimal wire speed and voltage settings, ensuring consistent and reliable welds. Also, consider the amperage. Web 59k views 9 months ago. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Web a general rule of thumb is you need 1 amp of power. Refer to the chart to determine each job’s optimal wire speed and voltage settings, ensuring consistent and reliable welds. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Also, consider the amperage settings and the task at hand. So, how many amps does it take. Web 59k views 9 months ago. Browse suggested weld parameter settings for stick welding, tig welding, mig (solid. Refer to the chart to determine each job’s optimal wire speed and voltage settings, ensuring consistent and reliable welds. Web flux core welding settings chart. Download the app version of the weld setting calculator for easy reference! Web flux cored welding calculator. Browse suggested weld parameter settings for stick welding, tig welding, mig (solid. A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. Web flux core welding settings chart. Web 59k views 9 months ago. But before using these values, we suggest that you have a decent understanding of your preferred metal. Browse suggested weld parameter settings for stick welding, tig welding, mig (solid. Here's a guide to setting it up the. A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. Web chart usage. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. What material are you welding? Here's a guide to setting it up the. Web 59k views 9 months ago. There is some nuance to it. Also, consider the amperage settings and the task at hand. But before using these values, we suggest that you have a decent understanding of your preferred metal. So, how many amps does it take to weld 3/8 steel? What material are you welding? This chart is essential for achieving proper weld. Refer to the chart to determine each job’s optimal wire speed and voltage settings, ensuring consistent and reliable welds. Also, consider the amperage settings and the task at hand. A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. Download the app version of the weld setting calculator for easy. So, how many amps does it take to weld 3/8 steel? Download the app version of the weld setting calculator for easy reference! Web flux cored welding calculator. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Web chart usage for various welding jobs. Web chart usage for various welding jobs. Browse suggested weld parameter settings for stick welding, tig welding, mig (solid. There is some nuance to it. A flux core mig welding wire speed and voltage chart can significantly simplify the setup process for different welding jobs. Web flux cored welding calculator. This chart is essential for achieving proper weld. Web flux core welding settings chart. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Here's a guide to setting it up the. What material are you welding? Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. But before using these values, we suggest that you have a decent understanding of your preferred metal. Also, consider the amperage settings and the task at hand.

instructions on welding in auto floor pan Grumpys Performance Garage

Understanding the Basics of FluxCored Wires Fabricating and Metalworking

What flux core wires to keep on hand? Welding Site

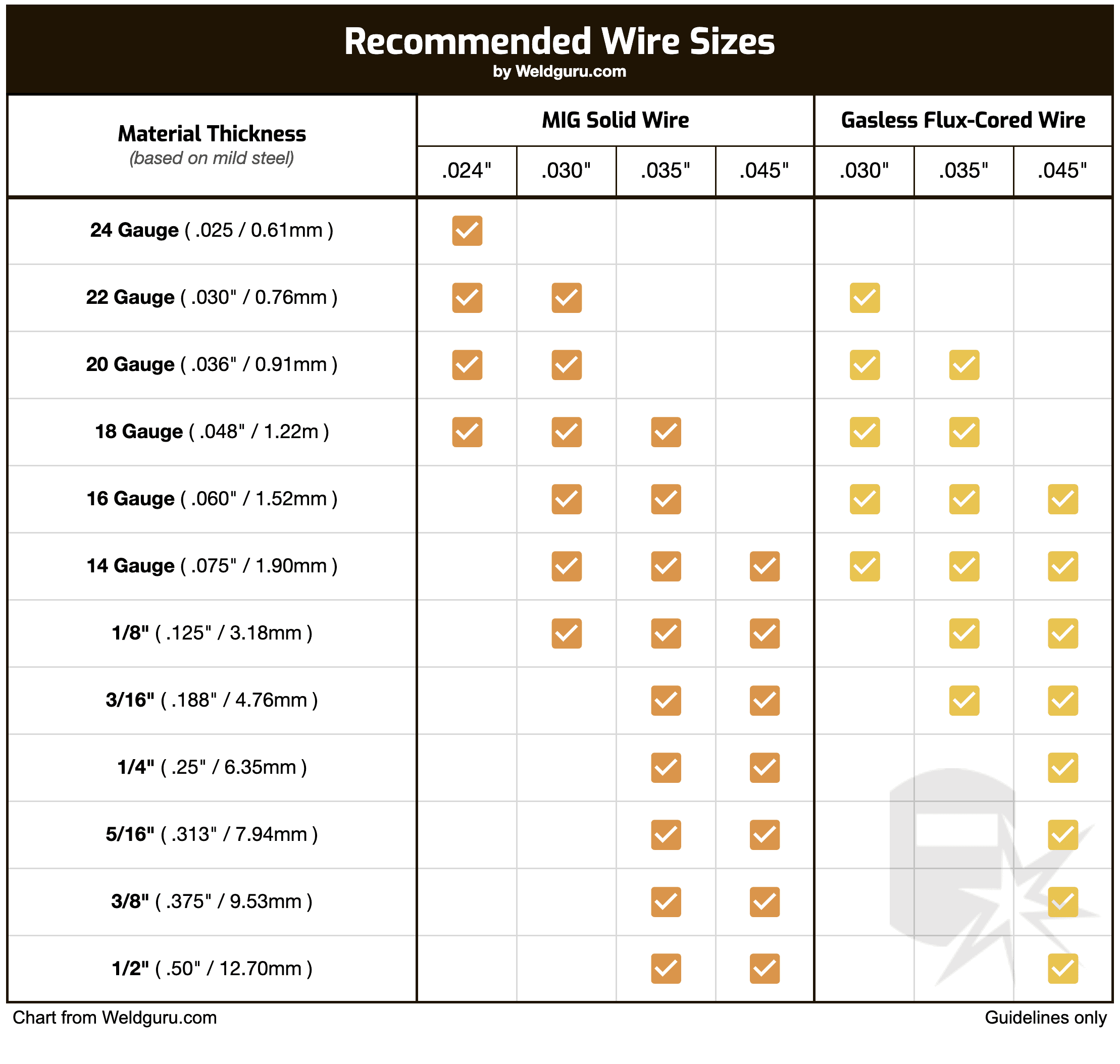

MIG Flux Core Welding Wire Types Specification (with Chart), 46 OFF

Flux Cored Arc Welding Wire Specs Welding Construction

Getting to Know Fluxcore Wire

MIG settings for welding different thickness mild steel

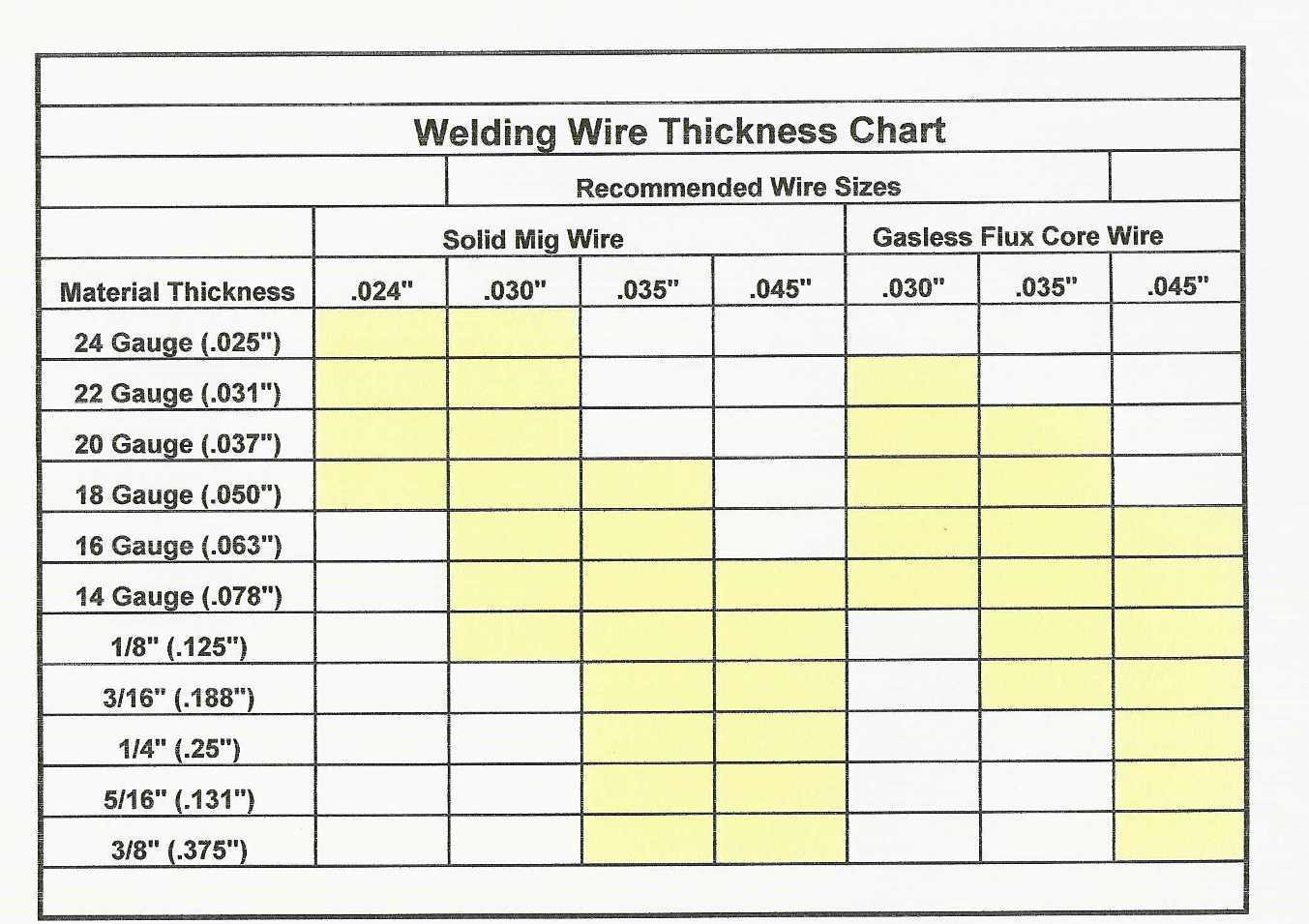

Flux Core Wire Size Chart

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

newbe initial review of yeswelder mig205ds using 110v flux core

Download The App Version Of The Weld Setting Calculator For Easy Reference!

So, How Many Amps Does It Take To Weld 3/8 Steel?

Refer To The Chart To Determine Each Job’s Optimal Wire Speed And Voltage Settings, Ensuring Consistent And Reliable Welds.

Web 59K Views 9 Months Ago.

Related Post: