Eye Bolt Lifting Capacity Chart

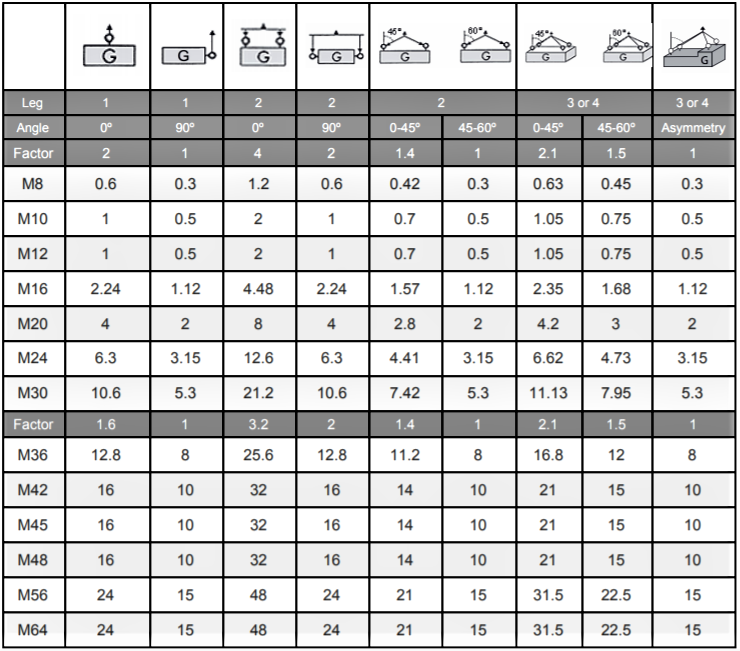

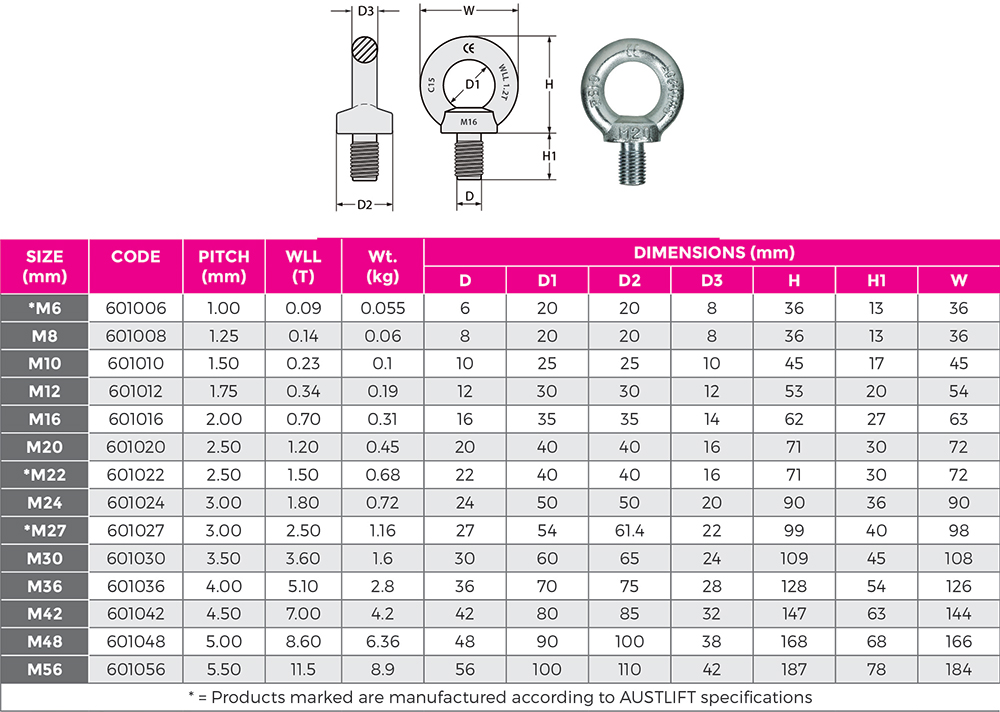

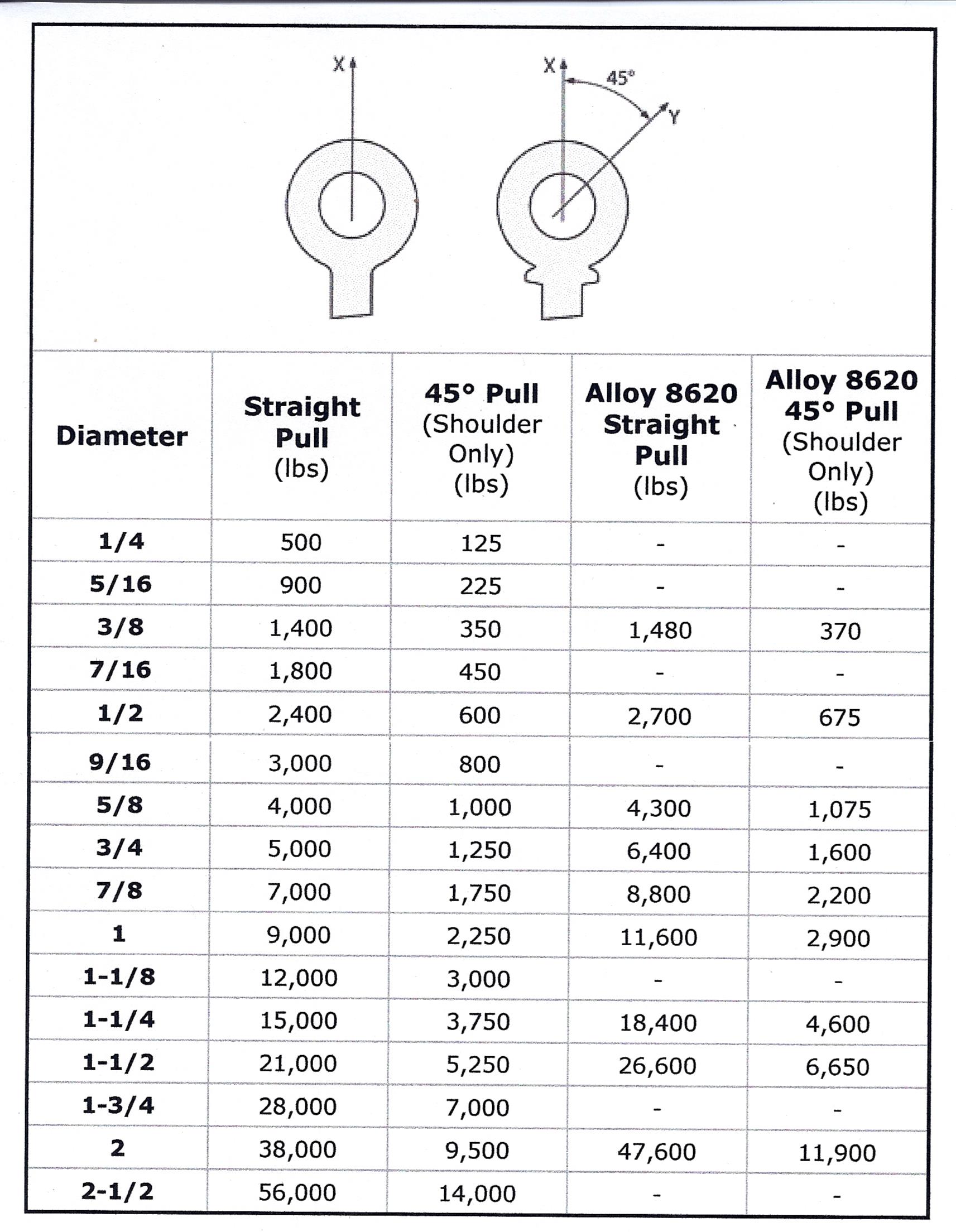

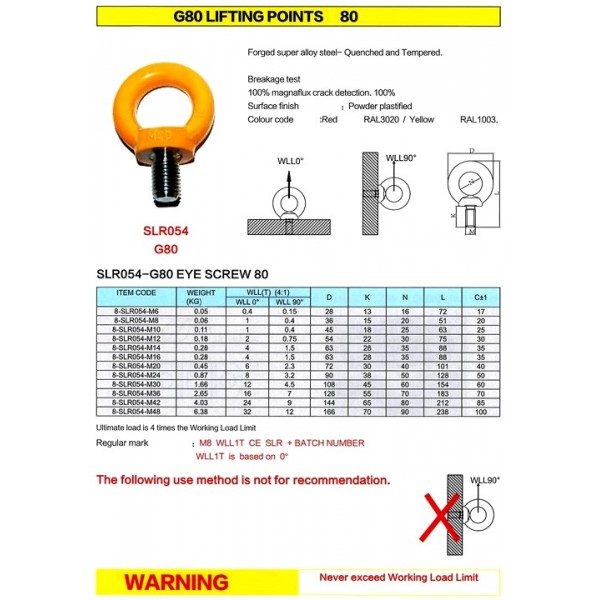

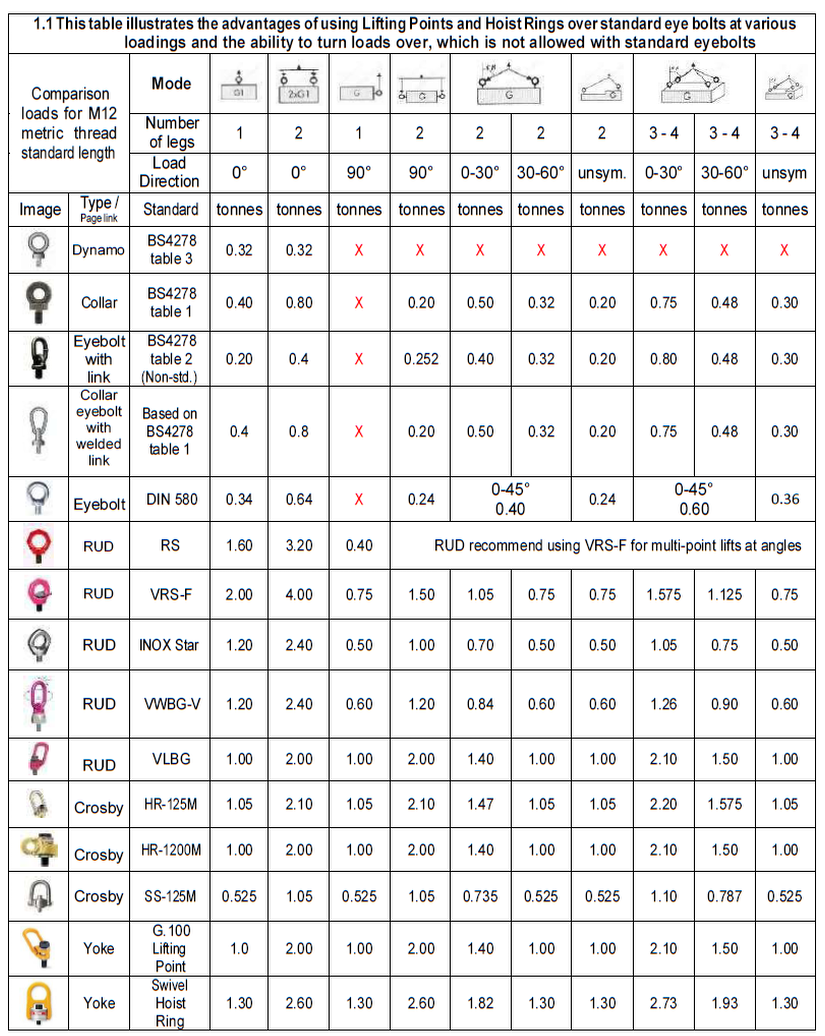

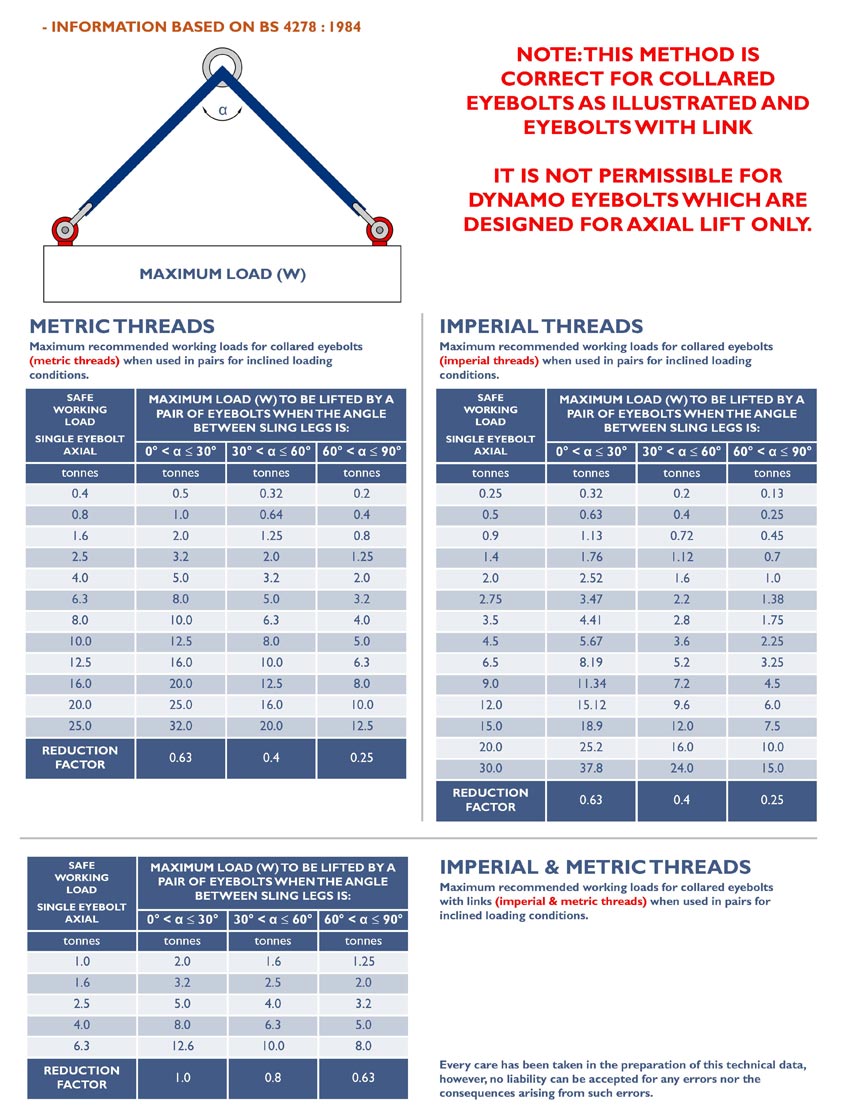

Eye Bolt Lifting Capacity Chart - The overall length measures the eyebolt from top to bottom. Web angular lifts significantly reduce rated capacities. Web the following charts and information will assist you: The minimum threaded shank length of eyebolts must be one thread diameter to attain the rated capacity. Working in pairs loads for inclined for collared loading eyebolts. The larger the diameter of the shank, the larger the working load limit. Web never exceed the work load limit of the eye bolt, see tables i & 2. Web forged eye bolt capacity and strength chart to show rated load capacities, proof load and breaking strength of a selected forged threaded eye bolt. Various sizes from m6 to m80. Meets or exceeds all requirements of asme b30.26 including identification, ductility, design factor, proof load and temperature requirements. Meanwhile, the thread length measures the intertwined area at the bottom. Web this is a ½” x 6 shoulder eye bolt and a ½” x 6 stainless steel lag eye bolt. Check seating after applying an angular lift since the initial lift may cause the bolt to back away from the load. Machinery lifting eye bolts in this catalog, and. No greater load should be applied to an eyebolt than the rated capacity listed. The overall length measures the eyebolt from top to bottom. Web angular lifts significantly reduce rated capacities. Working in pairs loads for inclined for collared loading eyebolts. Web ・can safely use swivel lifting eye bolt even when the lifting work from side direction, beveled direction or. The shank’s length determines the size from right below the eye to the end of the bolt. Web never exceed the work load limit of the eye bolt, see tables i & 2. Eye bolts according to this standard can be used in a temperature range from −20 ° c to +200 ° c without any restriction of the load.. When using lifting slings of two or more legs, make sure the loads in the legs are calculated using the angle from the vertical to the leg and properly size the shoulder nut. Working load limits for eye bolts are based on a straight vertical lift in a gradually increasing manner. Meanwhile, the thread length measures the intertwined area at. When the load is applied to the eye in this direction it will bend. If an angular lift is required, a properly seated shoulder pattern machinery eye bolt must be used. Web never exceed the work load limit of the eye bolt, see tables i & 2. Always insure hoist ring is free to align itself with sling. Angular lifts. The larger the diameter of the shank, the larger the working load limit. Shown at 0° (vertical) angle of lift. Three times allowance load with same bolt size. Web lifting eye bolt (din580) material steel, stainless steel 304 (a2) finishing steel comes in plain finishing d1 pitch d2 d3 d4 h l m6 1.0 20mm 36mm 20mm 36mm 14mm &. Web check with the bolt manufacturer to confirm exact weight capacity limits, but following is a helpful table that shows how much weight most eye bolts can hold. Angular lifts will significantly lower working load limits and should be avoided whenever possible. This column will help you know all your eyebolt’s length measurements. Always insure hoist ring is free to. Three times allowance load with same bolt size. For angle loading, see page 196. Web check with the bolt manufacturer to confirm exact weight capacity limits, but following is a helpful table that shows how much weight most eye bolts can hold. Angular lifts will significantly lower working load limits and should be avoided whenever possible. Web any angle beyond. Meanwhile, the thread length measures the intertwined area at the bottom. If such occurs, the eyebolt should be unloaded & properly reseated. Web angular lifts significantly reduce rated capacities. Web din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling. Load applied at an angle to the plane of the eye not recommended. The larger the diameter of the shank, the larger the working load limit. Machinery lifting eye bolts in this catalog, and other catalogs to which you may refer, could show a higher working load limit (wll), or rated capacity (rc). Web angular lifts significantly reduce rated capacities.. Web shank, thread, and overall length. Web any angle beyond vertical (axial lift ) will reduce the rating capacity refer to load charts. When the load is applied to the eye in this direction it will bend. Not recommended over 45 deg. Web table 1 makes reference to the safe working load for shoulder pattern eye bolts. Web din 580 specification specifies the properties of steel and stainless steel eyebolts and provides information on their correct use in lifting operations (as part of slings and as load handling equipment). Web working load limits for eye bolts are based on a straight vertical lift in a gradually increasing manner. The larger the diameter of the shank, the larger the working load limit. The overall length measures the eyebolt from top to bottom. Various sizes from m6 to m80. Web the following charts and information will assist you: Load limits are based on a safety factor of 5 to 1. Eye bolts according to this standard can be used in a temperature range from −20 ° c to +200 ° c without any restriction of the load. ・compared with chi, swivel lifting eye bolt has approx. Maximum pair of eyebolts load (w) when to be the lifted by a angle between sling legs is: Always insure hoist ring is properly torqued to required value.

Metric Eye Bolt Sizes Chart

AUSTLIFT Eye Bolt DIN580 Zinc The Lifting Guys

Swivel Eye Bolt Capacity Chart

Eye Bolt Capacity Chart

Eye Bolt Load Chart

Lifting Eye Bolt Size Chart Bolt About

Stainless Steel Eye Bolt With Shoulder & Ring SS Eye Bolt Screw Anchor

Swivel lifting eyes, eye bolts, swivel hoists, hoist rings from Rebar

A guide for lifting eye bolts and lifting points types and safe use

Collared Eyebolt Working Load Chart ©2022 Brooks Ltd.

Standard Shank Length Part No.

A Longer Shank Length Allows You To Go Through Thicker Objects.

Meets Or Exceeds All Requirements Of Asme B30.26 Including Identification, Ductility, Design Factor, Proof Load And Temperature Requirements.

Load Applied At An Angle To The Plane Of The Eye Not Recommended.

Related Post: