Engine Bearing Failure Chart

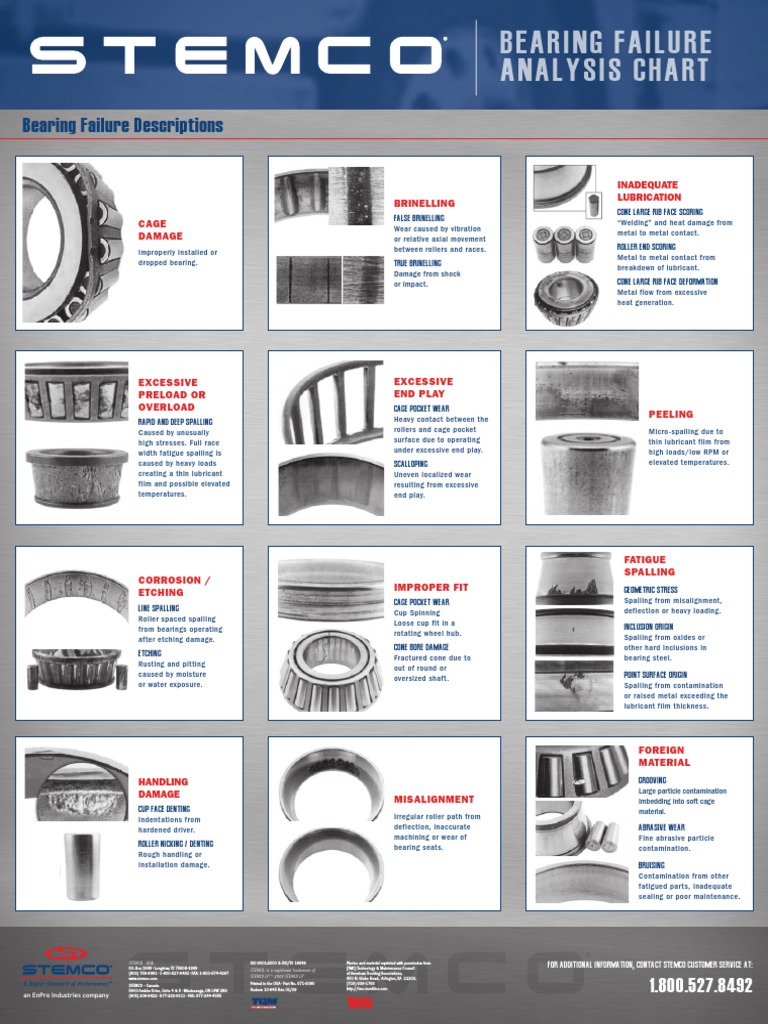

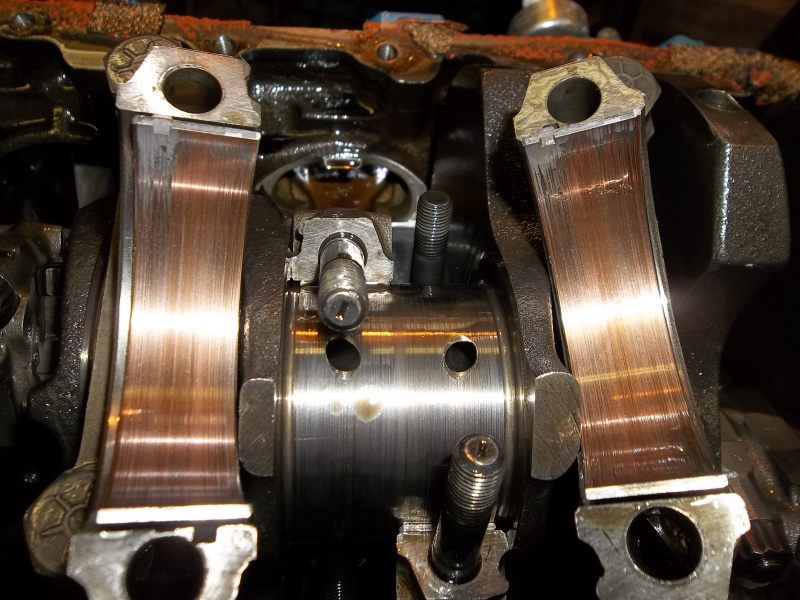

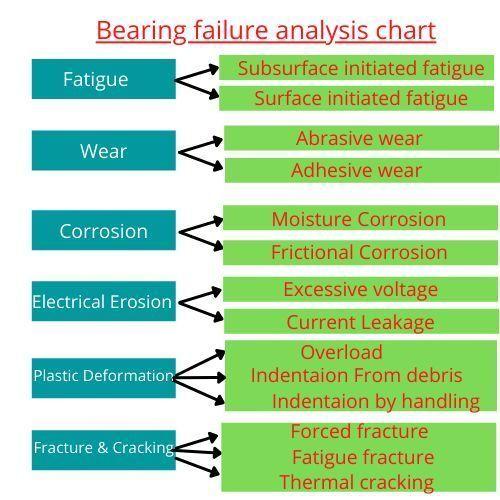

Engine Bearing Failure Chart - Engine bearings are integral components of any vehicle, ensuring the smooth operation of moving parts within the engine. Below are bad engine bearing. Fatigue of aluminum lining fatigue of babbitt fatigue of bronze edge wear due to overlay intermediate layer surface wear distorted connecting rod. When the engine bearing fails, it comes with some signs that are difficult to ignore. The usual result is increased vibration followed by wear, with subsequent increase in radial clearance or loss of preload. Bearings are built to last, so frequent failures may point to an installation or lubrication problem. Web car care hacks. Improperly installed or dropped bearing. Web determine the causes of the failure comparing the failure patterns with available standard photos from iso 15243 and/or bearing manufacturers. Web what are the symptoms of engine bearing failure? When the engine bearing fails, it comes with some signs that are difficult to ignore. Web what are the symptoms of engine bearing failure? Web bearing failure analysis chart. Analyze service and maintenance records and charts; Engine bearings are integral components of any vehicle, ensuring the smooth operation of moving parts within the engine. And secure application diagrams, graphics or engineering drawings. Improperly installed or dropped bearing. The pages of this manual are organized, for your convenience, into four major subjects: Web this guide will assist you in the initial diagnosis of the bearing condition. Web car care hacks. Skf bearing analysis experts can identify the cause of bearing failure and help you prevent it in the future. Most of the other bearing components can be repaired or replaced. However, it is important to note that in. Analyze service and maintenance records and charts; Web the following notes and illustrations, will assist you in the diagnosis and causes, of. The usual result is increased vibration followed by wear, with subsequent increase in radial clearance or loss of preload. Web the table below lists the eight major causes of premature engine bearing failure, along with percentage figures which indicate how often each has been found to be the prime contributor to a bearing’s premature failure. Web engine bearing failure analysis. Web bearings are symptoms of corrosion. Web engine bearing failure analysis guide. The wall thickness is usually measured across points 1 and 2 as shown in the. One sided wear is usually a misaligned or improperly adjusted assembly. Each fault covers the appearance, cause and recommended action to eliminate the fault in the future. Each fault covers the appearance, cause and recommended action to eliminate the fault in the future. Web 12 find the cause of bearing failures. Engine bearings are integral components of any vehicle, ensuring the smooth operation of moving parts within the engine. False brinelling wear caused by vibration or relative axial movement between rollers and races. Web bearings are symptoms. Most of engine bearing failures are caused by one of the two factors: Skf bearing analysis experts can identify the cause of bearing failure and help you prevent it in the future. Each fault covers the appearance, cause and recommended action to eliminate the fault in the future. You'll also find links to appropriate skf services and. Fatigue of the. Cold start failure is caused by lack of lubrication and running up to full rmp before the engine is warm. Analyze service and maintenance records and charts; Prepare an inspection sheet to capture all your observations. Engine bearing failure, can also occur, as. Web what are the symptoms of engine bearing failure? Web to calculate the failure rate, you’ll need to keep detailed records of bearing failures, including the time of failure and the operating conditions of the engine. However, when these essential elements begin to fail, they can. And secure application diagrams, graphics or engineering drawings. However, it is important to note that in many cases a premature. Cracks, cratered &. Web car care hacks. In addition, e xamples of resulting spectra are included to use as templates when identifying these common issues. Skf bearing analysis experts can identify the cause of bearing failure and help you prevent it in the future. Web the following sections help evaluate common machinery problems and identify their associated causes and effects. Web what are. However, when these essential elements begin to fail, they can. Fatigue of aluminum lining fatigue of babbitt fatigue of bronze edge wear due to overlay intermediate layer surface wear distorted connecting rod. Skf bearing analysis experts can identify the cause of bearing failure and help you prevent it in the future. Analyze service and maintenance records and charts; Web king engine bearings | innovation & performance Bearing damage (8.4 mb) bearing damage evaluation guide (918.3 kb) skf bearing maintenance handbook (14.2 mb) on these pages, you can find out more about bearing failure. Gather operating data from bearing monitoring devices; The usual result is increased vibration followed by wear, with subsequent increase in radial clearance or loss of preload. One sided wear is usually a misaligned or improperly adjusted assembly. The wall thickness is usually measured across points 1 and 2 as shown in the. However, it is important to note that in many cases a premature. Web engine bearing failure analysis guide. It will help to determine if the bearing can be a candidate for remanufacturing. Web this guide will assist you in the initial diagnosis of the bearing condition. Web engine bearing failure analysis guide. Dmitri kopeliovich research & development director.

Bearing Failure Poster English King Bearings Engine Bearing

Bearing Failure Analysis

Engine Bearing Failure Analysis Guide Engine Bearing Failure Analysis

Bearing Failure Analysys Chart Building Engineering Mechanical

Bearing Damage Reference Wall Chart RMS Ltd

Koyo bearingfailurechartposter

Bearing Damage Reference Wall Chart RMS Ltd

Bearing failure analysis chart CNC Prog

Ball Bearing Failure Chart

Engine Bearing Failure Chart

Fatigue Of The Bearing Material.

You'll Also Find Links To Appropriate Skf Services And.

Web 12 Find The Cause Of Bearing Failures.

When The Engine Bearing Fails, It Comes With Some Signs That Are Difficult To Ignore.

Related Post: