Electric Motor Grease Chart

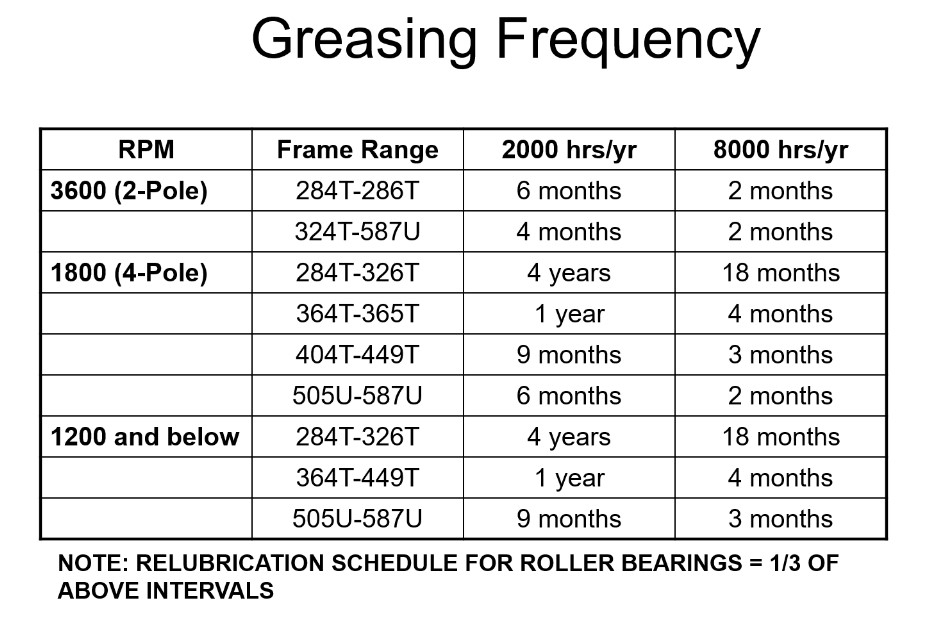

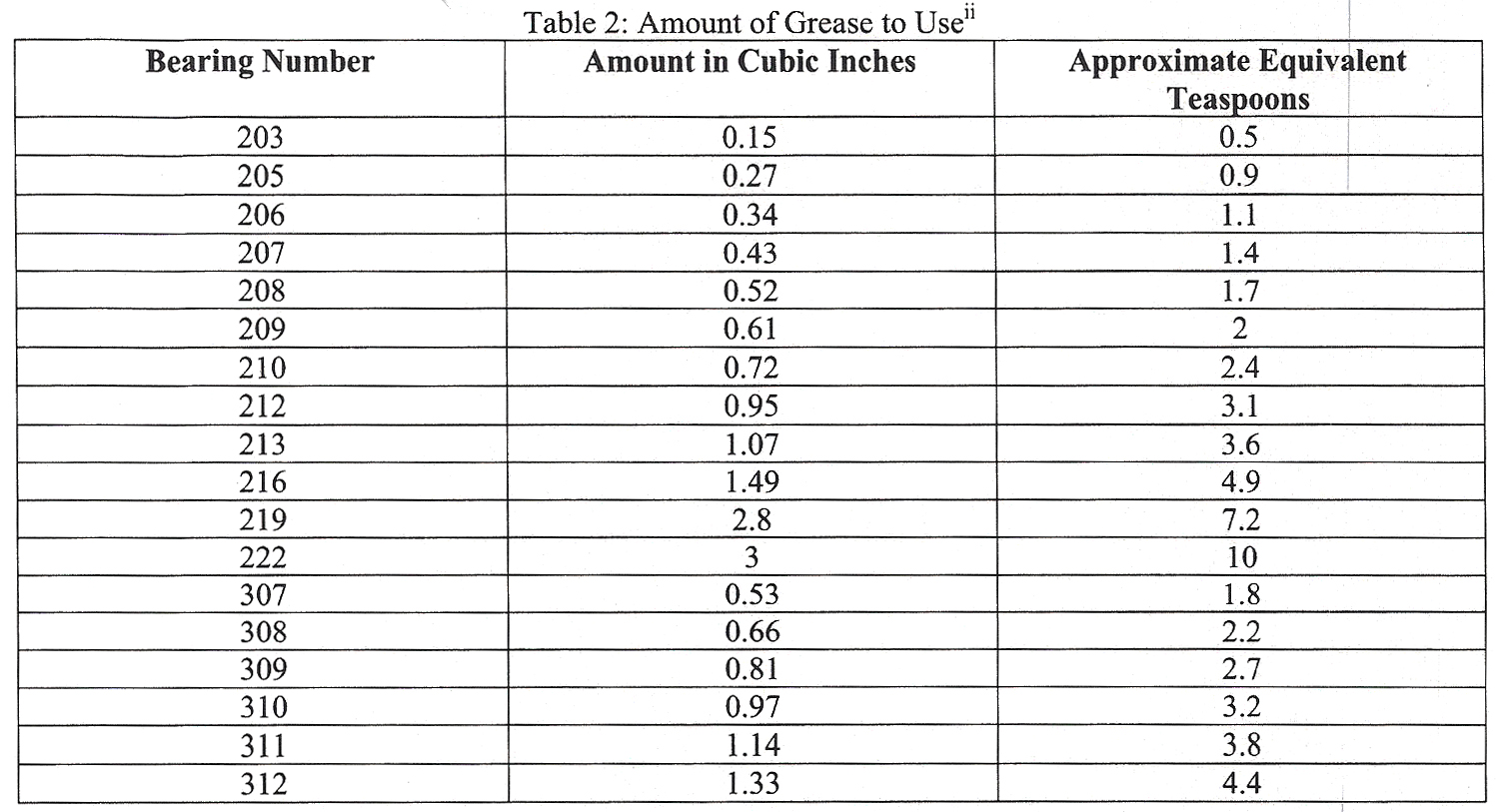

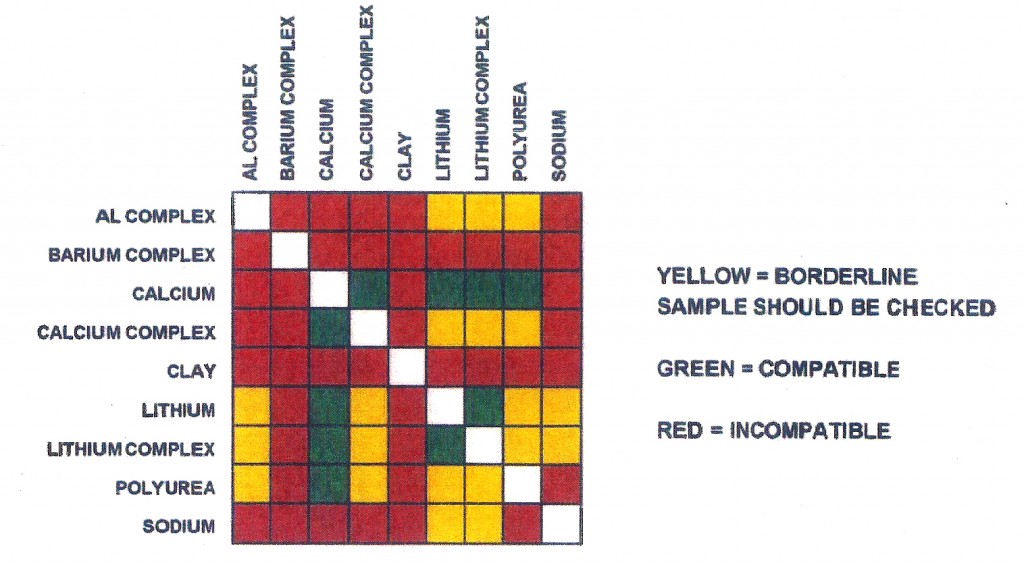

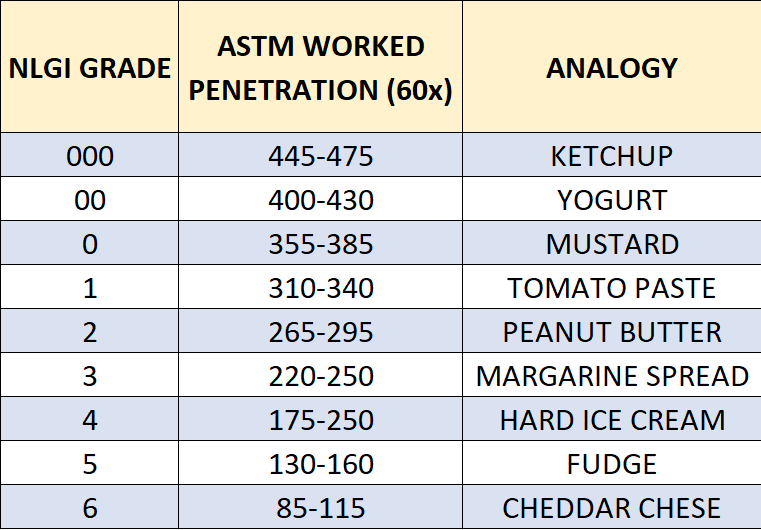

Electric Motor Grease Chart - Amount of grease to usethe general procedure for greasing is as follows:lock and tag out the electric motorwipe grease from the pressure fitting, clean dirt, debris. Web baldor motors are pregreased, normally with polyrex em (exxon mobil). Several characteristics are included within this “em” speciication, such as: Electric motors require lubricants with specific characteristics. Web select the right grease and suggest frequency and quantity, while taking into account the particular conditions of your application. Increased durability compared to conventional greases. General guidelines for typical greases for. It is suitable for electric motors and similar applications. Web nates electric motor quality as required by most electric motor customers. These bearings are predisposed to fail along with your. First, the grease consistency preferred for electric motors is normally nlgi 2 or 3, with a base. Web electric motor bearing grease should soften no more than 1 to 1.5 nlgi grades in this test. Web learn how to prevent electric motor failures by choosing the right grease, volume and interval. Increased durability compared to conventional greases. Web in electric. It is suitable for electric motors and similar applications. Web electric motor bearing grease should soften no more than 1 to 1.5 nlgi grades in this test. Web this article explains what you need to know about how grease works and how to choose the right grease to protect your electric motors. Web baldor motors are pregreased, normally with polyrex. An electric motor bearing grease that softens more than that may leak out of the. You’ll also find an easy. Web mobil polyrex em electric motor bearing grease provides: If other greases are preferred, check with a local baldor service center for recommendations. Amount of grease to usethe general procedure for greasing is as follows:lock and tag out the electric. Increased durability compared to conventional greases. Please use this chart for proper orientation of plugs. Bearing size, hours of operation, rpm, bearing type, etc. Electric motors require lubricants with specific characteristics. Web electric motor bearing grease should soften no more than 1 to 1.5 nlgi grades in this test. Web this article explains what you need to know about how grease works and how to choose the right grease to protect your electric motors. Web the grease selection chart (pdf) provides you with a complete overview of skf greases. Find out how to use condition monitoring equipment and single. Web select the right grease and suggest frequency and quantity,. Web this article explains what you need to know about how grease works and how to choose the right grease to protect your electric motors. Web the manufacturer of these products, baldor electric company, became abb motors and mechanical inc. Web mobil polyrex em electric motor bearing grease provides: Amount of grease to usethe general procedure for greasing is as. Web the grease selection chart (pdf) provides you with a complete overview of skf greases. These bearings are predisposed to fail along with your. Web electric motor bearing grease. If other greases are preferred, check with a local baldor service center for recommendations. You’ll also find an easy. Web the grease selection chart (pdf) provides you with a complete overview of skf greases. Electric motors require lubricants with specific characteristics. Please use this chart for proper orientation of plugs. The chart includes the main selection parameters, such as temperature, speed and. Increased durability compared to conventional greases. Web learn how to prevent electric motor failures by choosing the right grease, volume and interval. Please use this chart for proper orientation of plugs. If other greases are preferred, check with a local baldor service center for recommendations. Find out how to use condition monitoring equipment and single. Bearing size, hours of operation, rpm, bearing type, etc. It is suitable for electric motors and similar applications. Web the manufacturer of these products, baldor electric company, became abb motors and mechanical inc. Several characteristics are included within this “em” speciication, such as: Increased durability compared to conventional greases. Web learn how to prevent electric motor failures by choosing the right grease, volume and interval. Web the manufacturer of these products, baldor electric company, became abb motors and mechanical inc. Web learn how to prevent electric motor failures by choosing the right grease, volume and interval. You’ll also find an easy. Web electric motor bearing grease. These bearings are predisposed to fail along with your. It is suitable for electric motors and similar applications. Web mobil polyrex em electric motor bearing grease provides: Increased durability compared to conventional greases. Web mobil polyrex em electric motor bearing grease provides: Increased durability compared to conventional greases. If other greases are preferred, check with a local baldor service center for recommendations. Web in electric motors, several factors determine how often a bearing should be greased: The chart includes the main selection parameters, such as temperature, speed and. Find out how to use condition monitoring equipment and single. An electric motor bearing grease that softens more than that may leak out of the. Web nates electric motor quality as required by most electric motor customers.

How to Grease your Electric Motor Bearings YouTube

Properly Lubricate Electric Motors Efficient Plant

Electric Motor Grease Chart

How Often Should You Grease An Electric Motor

Electric Motor Bearing Lubrication

How To Grease A Electric Motor

What is the Best Grease for My Car? AP, MP Grease or EP Grease...

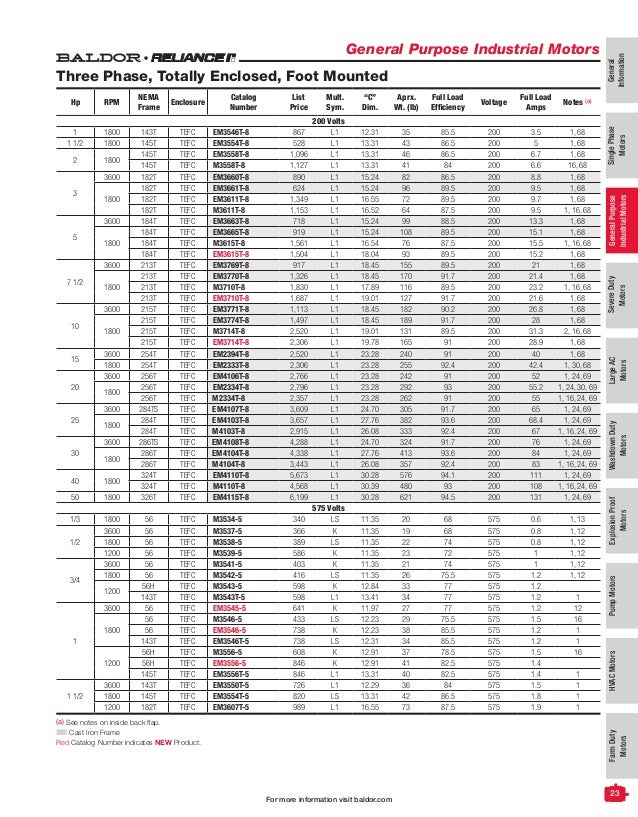

Baldor Motor Grease Chart

Everything You Need To Know About Greases RS Components RS Philippines

UNO GREASE MAX How to Design an Electric Motor Regreasing Program

First, The Grease Consistency Preferred For Electric Motors Is Normally Nlgi 2 Or 3, With A Base.

Bearing Size, Hours Of Operation, Rpm, Bearing Type, Etc.

Web Electric Motor Bearing Grease Should Soften No More Than 1 To 1.5 Nlgi Grades In This Test.

Web This Article Explains What You Need To Know About How Grease Works And How To Choose The Right Grease To Protect Your Electric Motors.

Related Post: