Dowel Pin Tolerance Chart

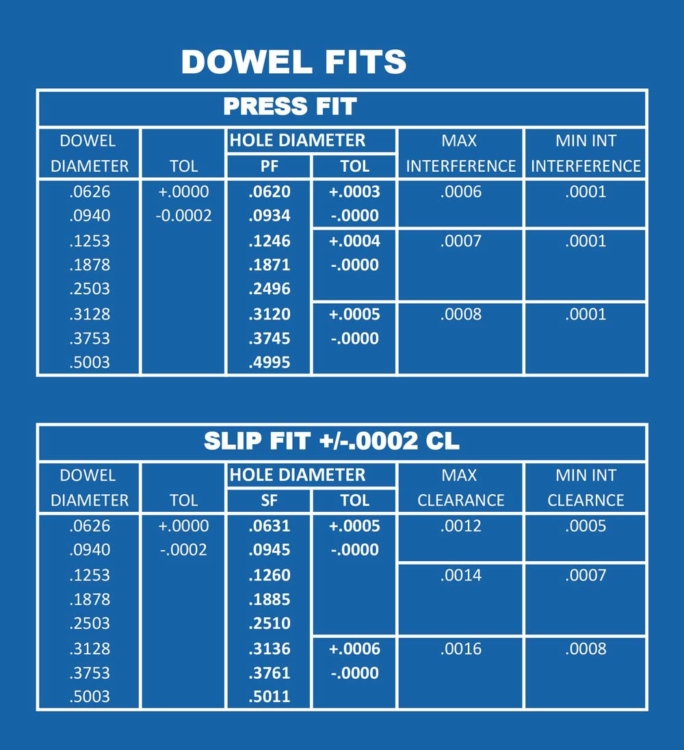

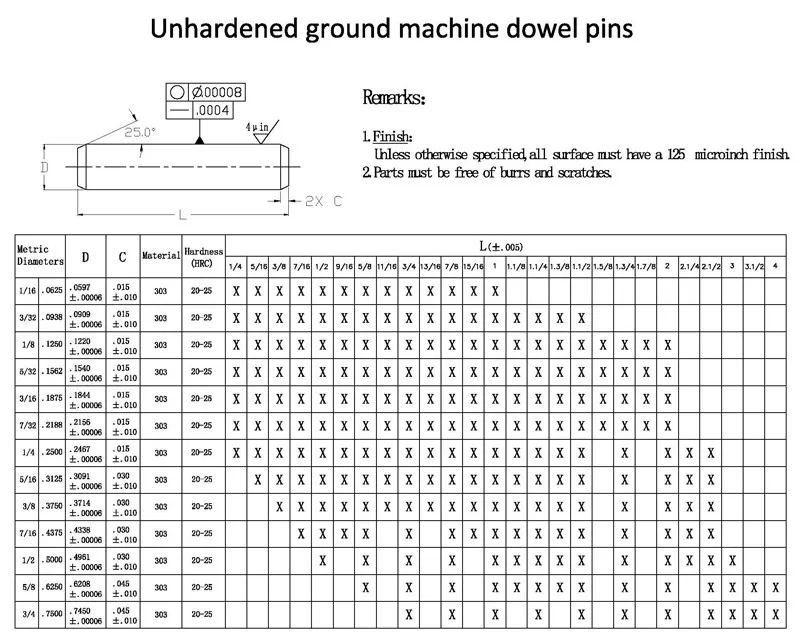

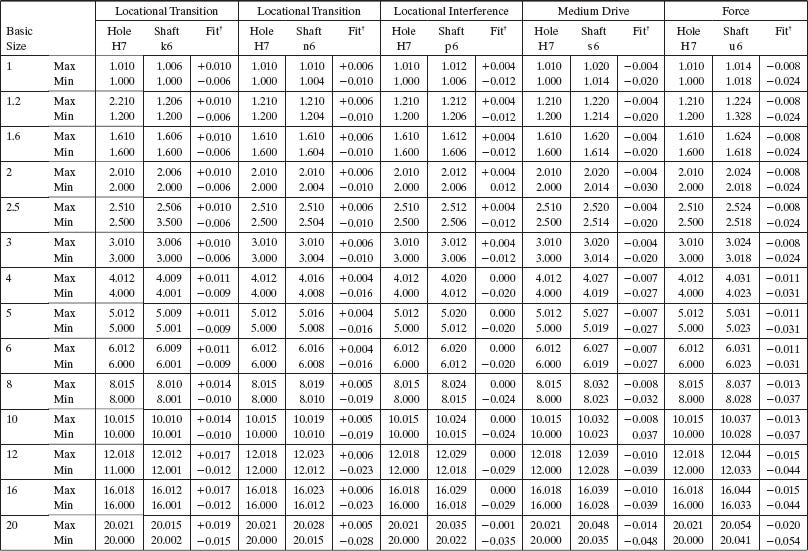

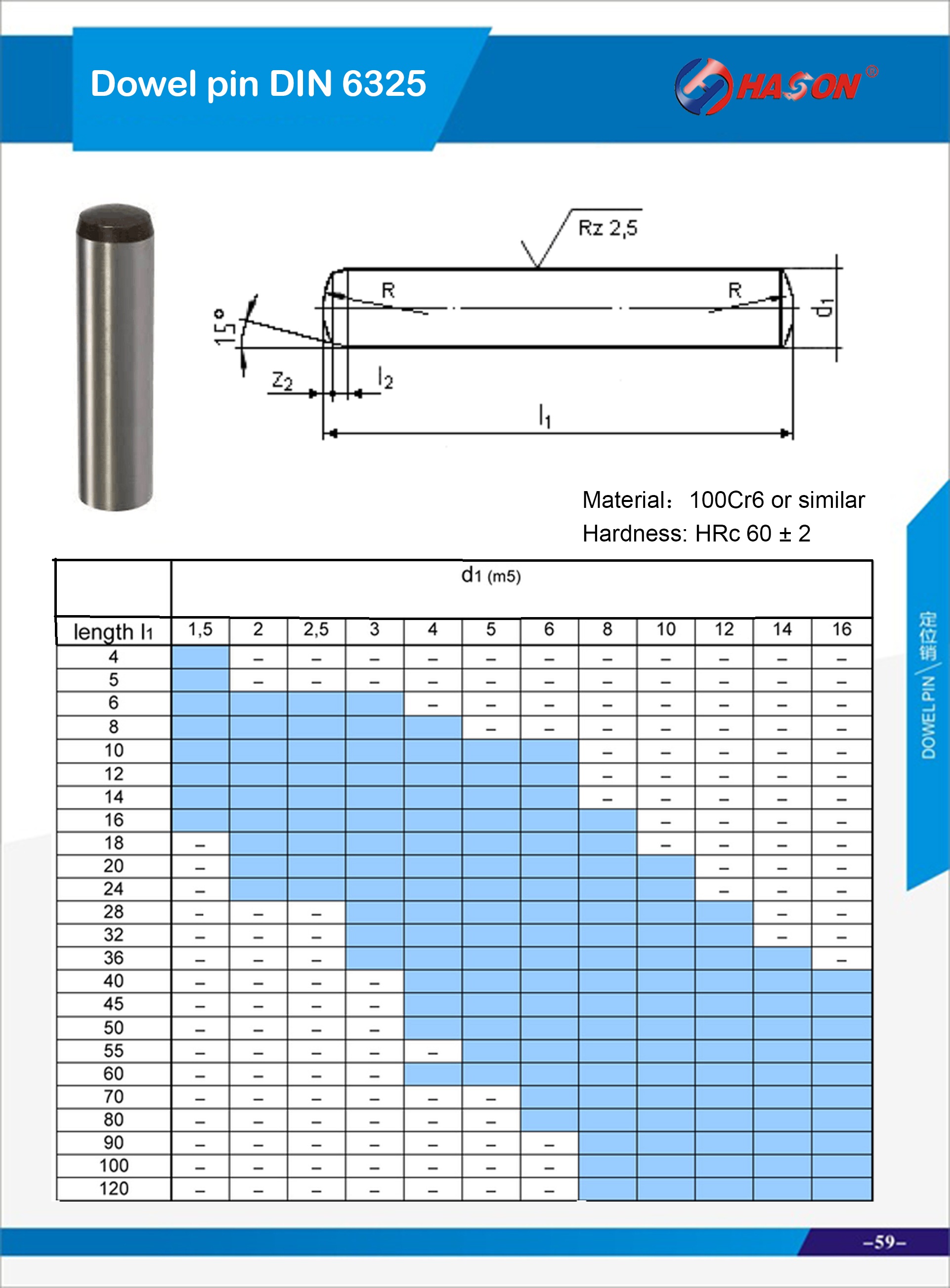

Dowel Pin Tolerance Chart - We’ve broken down the tolerances into 3 basic families here: Verify solid pin with proper end designs. Web limits, fits and tolerances (iso and ansi systems) interference (press & shrink) fit calculator; Find the part in the chart above. Machine dowel pins chart ansi asme. Preferred tolerances and fits charts (ansi) precision measuring tools for. The tolerance should be carefully chosen to ensure a. Also used as bearings, gages, precision parts, etc. Web we generally recommend the below tolerances when inserting a pin: Dowel length (l) is recommended to be 4 times the dowel diameter (d) 2. Pins to be supplied in natural finish. Depth of fixed portion (f) is recommended to be 1.5 to 2 times the dowel diameter 3. Dowel length (l) is recommended to be 4 times the dowel diameter (d) 2. Web we generally recommend the below tolerances when inserting a pin: Also used as bearings, gages, precision parts, etc. Yes, tolerances for standard inch size dowel pins would be per the ansi b18. Web generally the fits are also dictated by the material that the dowel pins are inserted into. Web limits, fits and tolerances (iso and ansi systems) interference (press & shrink) fit calculator; Dowel length (l) is recommended to be 4 times the dowel diameter (d) 2.. Find the part in the chart above. Dowel length (l) is recommended to be 4 times the dowel diameter (d) 2. Yes, tolerances for standard inch size dowel pins would be per the ansi b18. Preferred tolerances and fits charts (ansi) precision measuring tools for. Depth of fixed portion (f) is recommended to be 1.5 to 2 times the dowel. Web limits, fits and tolerances (iso and ansi systems) interference (press & shrink) fit calculator; Dowel length (l) is recommended to be 4 times the dowel diameter (d) 2. Web dowel pin installation design tolerance table chart. Web a chart below is provided for metric dowel pin sizes. The tolerance should be carefully chosen to ensure a. These tolerances are normally down through the “limit” option in solidworks, indicating the maximum and minimum. Surface roughness ra < 0,8 µm workmanship pins. Web generally the fits are also dictated by the material that the dowel pins are inserted into. Web if the tolerance of the metal dowel pin is dictated by the standard to which it is manufactured,. Yes, tolerances for standard inch size dowel pins would be per the ansi b18. Web a chart below is provided for metric dowel pin sizes. Machine dowel pins chart ansi asme. Depth of fixed portion (f) is recommended to be 1.5 to 2 times the dowel diameter 3. Web generally the fits are also dictated by the material that the. Verify solid pin with proper end designs. Pins to be supplied in natural finish. Asme/ansi machine dowel pins chart for. Standard unhardened ground dowel pins. Depth of fixed portion (f) is recommended to be 1.5 to 2 times the dowel diameter 3. Web find the press fit and slip fit hole dimensions for dowel pins used for alignment of mating parts. Design for dowel pin press fit. Web we generally recommend the below tolerances when inserting a pin: Web limits, fits and tolerances (iso and ansi systems) interference (press & shrink) fit calculator; Dowel length (l) is recommended to be 4 times. Find the part in the chart above. The tolerance should be carefully chosen to ensure a. Surface roughness ra < 0,8 µm workmanship pins. Verify solid pin with proper end designs. The schematic representation of the fit is also. Web find the press fit and slip fit hole dimensions for dowel pins used for alignment of mating parts. All tolerances shall apply prior to the application of a plating or coating. Design for dowel pin press fit. Web a chart below is provided for metric dowel pin sizes. Asme/ansi machine dowel pins chart for. Verify solid pin with proper end designs. Yes, tolerances for standard inch size dowel pins would be per the ansi b18. Web dowel pin installation design tolerance table chart. Preferred tolerances and fits charts (ansi) precision measuring tools for. The chart covers various dowel pin diameters and hole depths, and shows the. Web if the tolerance of the metal dowel pin is dictated by the standard to which it is manufactured, then you do not need to mention the tolerance at time of order. Depth of fixed portion (f) is recommended to be 1.5 to 2 times the dowel diameter 3. The tolerance should be carefully chosen to ensure a. Dowel length (l) is recommended to be 4 times the dowel diameter (d) 2. The schematic representation of the fit is also. We’ve broken down the tolerances into 3 basic families here: Web find the press fit and slip fit hole dimensions for dowel pins used for alignment of mating parts. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can. Machine dowel pins chart ansi asme. Asme/ansi machine dowel pins chart for. Web we generally recommend the below tolerances when inserting a pin:

Dowel Pin Hole Tolerance Chart

Dowel Pin Slip Fit Tolerance Chart

Press Fit Dowel Pin Tolerance Chart

Catalog Dowels and Other Pins Stainless Steel Engineering Tolerance

Dowel Pin Tolerance and Fit Standards by Factorem Medium

Dowel Pin Fit Chart

Dowel Pin Tolerances PDF PDF Engineering Tolerance Steel

Dowel Pin Hole Size Chart

A Comprehensive Guide To The Metric Dowel Pin Hole Tolerance Chart

A Comprehensive Guide To The Metric Dowel Pin Hole Tolerance Chart

Find The Part In The Chart Above.

Web A Chart Below Is Provided For Metric Dowel Pin Sizes.

Design For Dowel Pin Press Fit.

Also Used As Bearings, Gages, Precision Parts, Etc.

Related Post: