Dot Tire Tread Depth Chart

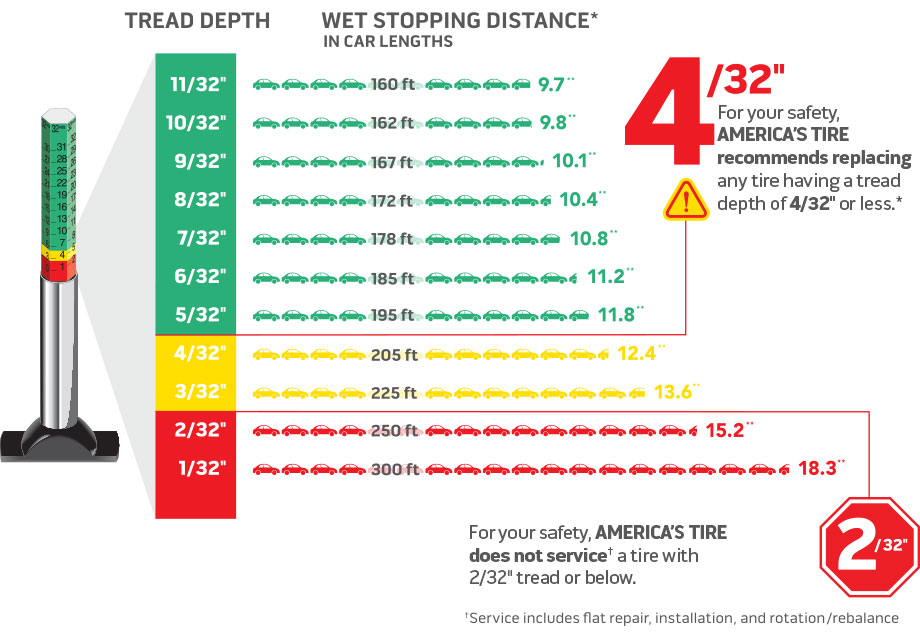

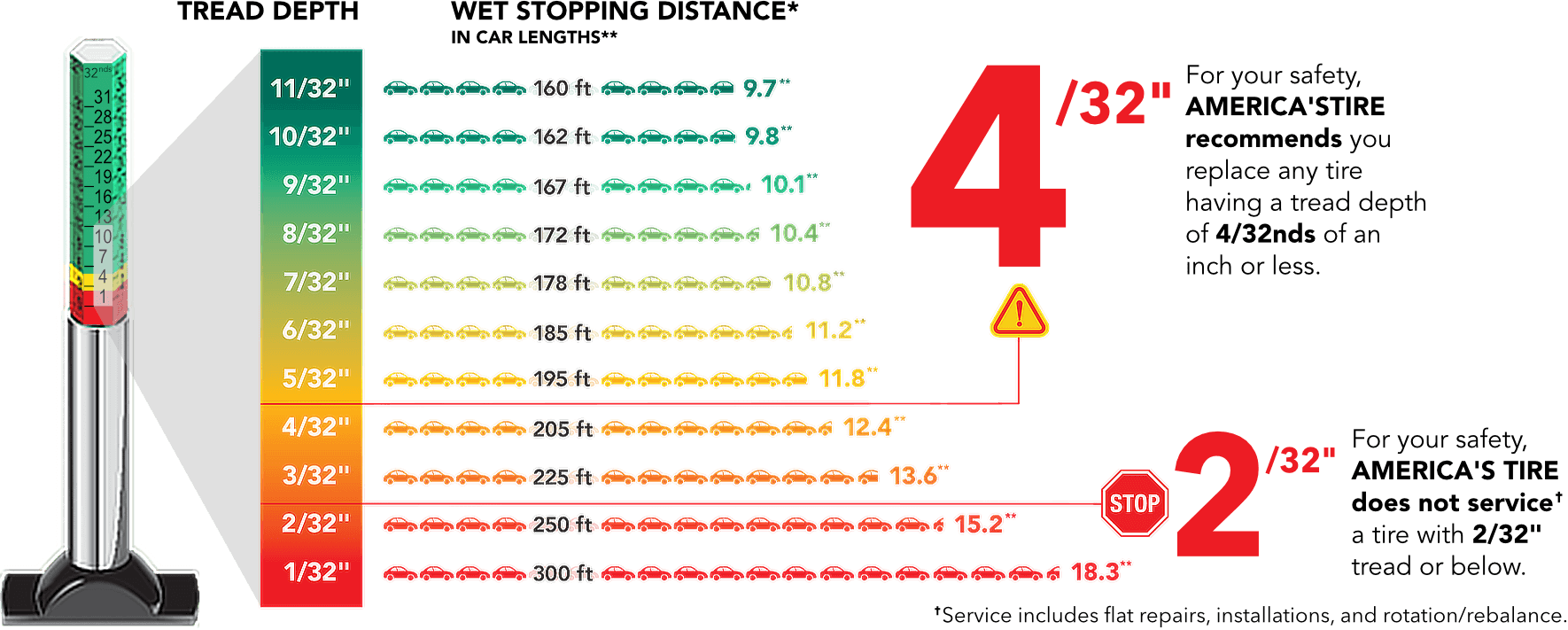

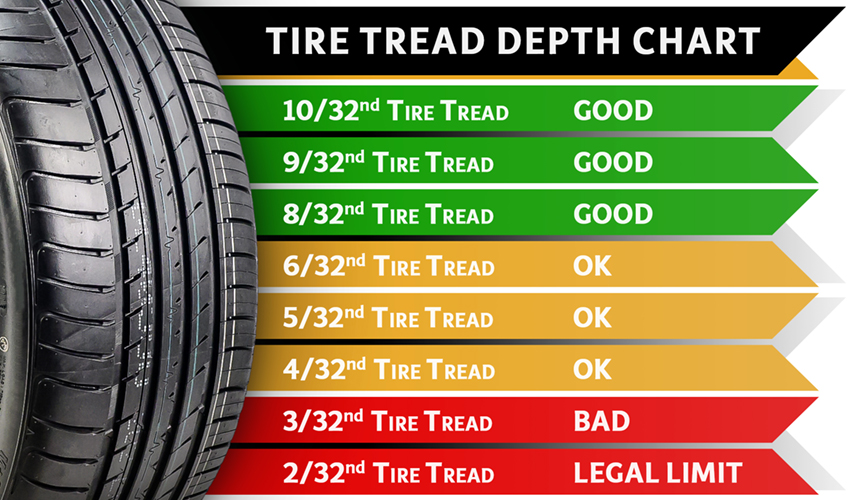

Dot Tire Tread Depth Chart - Web tire tread depth refers to the grooves between the main blocks on the contact surface of a tire. Lincoln penny can also be used to confirm the tire's tread depth. • irregular treadwear • cracking • bulges • cuts • foreign objects • other damage • inadequate tread depth and bring it to the attention of your mechanic. Web the department of transportation (dot) requires that all commercial trucks have tires with a minimum tread depth of 2/32″. It’s important to perform regular tire maintenance to avoid uneven tread wear, good traction on wet roads, and long tread life. As you rack up the miles, the soft rubber compound, the very thing that gives you traction, wears away. Why is tire tread depth so important? Web the national highway traffic safety administration’s (nhtsa’s) office of defects investigations (odi) have highlighted that exceeding tire speed ratings, increased front axle loads, and increased uptime/equipment utilization have led to increased tire failures on commercial trucks. I nflation pressure • gauge your tires cold before each trip • adjust as necessary improper inflation pressure affects tire wear and fuel. All other truck or trailer tires must have at least 2/32 of an inch to be within the minimum legal tread depth. Steer tires must have a minimum depth of tread of 2/32 of an inch. • irregular treadwear • cracking • bulges • cuts • foreign objects • other damage • inadequate tread depth and bring it to the attention of your mechanic. Web learn about the dot and fmcsa minimum tread depth requirements for your truck tires—and why they matter!. Because it is difficult to accurately measure tread depth with a ruler, tread depth is best measured with a tire tread depth gauge. Web the legal minimum in most states is 2/32″. For the average driver, measuring tire tread depth will not always be on their mind. • irregular treadwear • cracking • bulges • cuts • foreign objects •. Your tires can offer a reduced risk of punctures, better traction, and a greater ability to push the water away to get rid of hydroplaning on the wet roads when the tires are on or above the tread depth level that is recommended. • irregular treadwear • cracking • bulges • cuts • foreign objects • other damage • inadequate. I nflation pressure • gauge your tires cold before each trip • adjust as necessary improper inflation pressure affects tire wear and fuel. The cvsa requires steer tires to have a minimum tread. Web according to federal motor carrier safety administration (fmcsa) regulations, the minimum tread depth for a steer tire is 4/32 of an inch on every major tread. It’s important to perform regular tire maintenance to avoid uneven tread wear, good traction on wet roads, and long tread life. Web the typical new tire used on automobiles is measured with 10/32” to 11/32” of tread depth. The tread depth helps a tire have the proper traction, controllability, and performance. Without normal tire tread depth, the vehicle can easily. It’s important to perform regular tire maintenance to avoid uneven tread wear, good traction on wet roads, and long tread life. Understanding tire tread depth is crucial for driving safety. Web the dot tread depth regulations say that any tire on the front wheels of a bus, truck, or truck tractor should have a tread groove depth of at least. When tires have neared the end of their life, a u.s. • irregular treadwear • cracking • bulges • cuts • foreign objects • other damage • inadequate tread depth and bring it to the attention of your mechanic. Web tread wear is measured in 32nds of an inch from 11 or 10/32″ for new tires, 4/32″ for when it’s. Web tread wear indicators, often found as raised sections interspersed in the grooves of your tire, signal when a tire’s tread has worn down to 2/32 of an inch or 1.6 millimeters, indicating a need for replacement. Web the dot tread depth regulations say that any tire on the front wheels of a bus, truck, or truck tractor should have. The cvsa requires steer tires to have a minimum tread. Web tread wear indicators, often found as raised sections interspersed in the grooves of your tire, signal when a tire’s tread has worn down to 2/32 of an inch or 1.6 millimeters, indicating a need for replacement. The tread depth helps a tire have the proper traction, controllability, and performance.. Lincoln penny can also be used to confirm the tire's tread depth. Web 2/32” tread depth shows that your tires have to be replaced as they are legally bald. Because it is difficult to accurately measure tread depth with a ruler, tread depth is best measured with a tire tread depth gauge. The cvsa also has minimum tread depth, which. If one spot on one. Web the national highway traffic safety administration’s (nhtsa’s) office of defects investigations (odi) have highlighted that exceeding tire speed ratings, increased front axle loads, and increased uptime/equipment utilization have led to increased tire failures on commercial trucks. Tread depth is crucial to channel water out from underneath the contact patch of your tires. I nflation pressure • gauge your tires cold before each trip • adjust as necessary improper inflation pressure affects tire wear and fuel. • irregular treadwear • cracking • bulges • cuts • foreign objects • other damage • inadequate tread depth and bring it to the attention of your mechanic. Web learn about the dot and fmcsa minimum tread depth requirements for your truck tires—and why they matter! For the average driver, measuring tire tread depth will not always be on their mind. Web the legal minimum in most states is 2/32″. Web dive into the world of tire safety with our comprehensive article revealing minimum tread depth standards globally. Web dot tire tread depth regulations. The treads provide grip on the road as you drive. Your tires can offer a reduced risk of punctures, better traction, and a greater ability to push the water away to get rid of hydroplaning on the wet roads when the tires are on or above the tread depth level that is recommended. Web these department of transportation (dot) truck tire tread depth regulations are more stringent than regulations set by the cvsa, outlined below. Web according to dot tire regulations, the minimum tire tread depth for steer tires or any tire on the front wheel is 4/32 of an inch. Steer tires must have a minimum depth of tread of 2/32 of an inch. Web in the united states, tread depth is measured in 32nds of an inch.

DOT Tire Regulations Ultimate Guide My Safety Manager

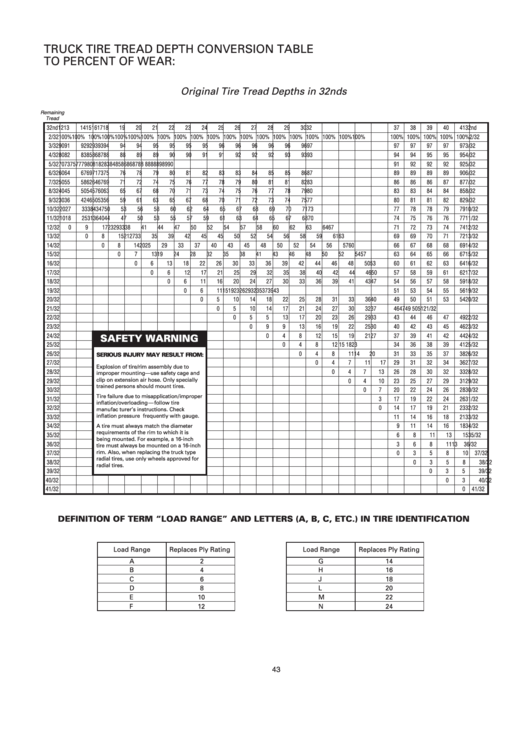

Tire Thread Depth Conversion Table printable pdf download

Tire tread depth and DOT regulations Motive

Dot Tire Tread Depth Chart

Tire Safety Facts Tire Age, Air Pressure, Tread Safety America's Tire

Tire Safety Facts Tire Age, Air Pressure, Tread Safety America's Tire

Tire Tread Depth Chart amulette

DOT Tire Regulations Ultimate Guide My Safety Manager

Winter Tire Tread Depth

Dot Regulations Complete Guide About Tire Tread Depth Fleet Care

Web This Inspection Bulletin Explains How To Properly Measure Tread Depth Of Commercial Motor Vehicle Tires That Utilize Evolving Tread Designs.

Web The Department Of Transportation (Dot) Requires That All Commercial Trucks Have Tires With A Minimum Tread Depth Of 2/32″.

Web 2/32” Tread Depth Shows That Your Tires Have To Be Replaced As They Are Legally Bald.

This Helps Ensure Enough Grip On The Road In Wet Or Slippery Conditions.

Related Post: