Dmc Pin Chart

Dmc Pin Chart - In this example, the bin number is 260. Each tool body is set for a different poundage range (see chart a on back of this page). Crimping is a popular topic at element 14, it seems we all love our crimping tools. Web standard dmc power configuration these dimensions are consistent throughout this product line and will not be repeated in each table. Web dmc has worked closely with the world’s leading connector accessory manufacturers and standards organisations to develop the necessary tooling and accessories to meet the stringent demands of aerospace and defence system. Acsr thermal mechanical white paper. These tools check the retention of pins and sockets in electrical connectors by indicating when proper pressure has been applied. Refer to chart b for tip part numbers. Refer to the table below for the color code reference. Web tips on how to properly crimp wires and pin connectors. Talk with us directly using livechat. To test retention of socket contacts, use socket tester tip with preset tool. Each tool body is set for a different poundage range (see chart a on back of this page). Power contact wall chart (m39029) updated: Web refer to chart a for preset range of tool. Each tool body is set for a different poundage range (see chart a on back of this page). Web our indent crimp tools are designed with extreme precision to deliver 8, 4, and 2 indent crimps. Web it lists the connector information, including part numbers, color code, pin/socket type, wire range and required crimp tool, accessory, and assembly tools for. Refer to chart b for tip part numbers. Marking includes dmc power part number and tooling swage die part number dmc size bus size c dia (o.d.) d min. Refer to the table below for the color code reference. Each tool body is set for a different poundage range (see chart a on back of this page). 9 pin tips. A slightly more uncommon tool for hobbyists, but very common for industrial, military, automotive and aerospace purposes, is the pin crimping tool. Swage tooling quick start guide. Insert tester (pin) into mating end of contact. Web our indent crimp tools are designed with extreme precision to deliver 8, 4, and 2 indent crimps. Crimping is a popular topic at element. Remove button head (shipping) screw. In this example, the bin number is 260. Acsr thermal mechanical white paper. Talk with us directly using livechat. Our precision tooling has supported the defense and aerospace industries for over 75 years. Acsr thermal mechanical white paper. A slightly more uncommon tool for hobbyists, but very common for industrial, military, automotive and aerospace purposes, is the pin crimping tool. Referring to the diagram, the order starts from the very end of the wire barrel end and continues towards the mating end. Web tips on how to properly crimp wires and pin connectors.. Acsr thermal mechanical white paper. The tester tips are color coded for specific sizes (awg 4, Dmc tools cover all aspects of building wire harnesses and connector assembly including crimpers, strippers, insertion/removal tools, tensile testing, banding, and more! Refer to chart b for tip part numbers. In this example, the bin number is 260. Each tool body is set for a different poundage range (see chart a on back of this page). Refer to chart b for tip part numbers. These tools check the retention of pins and sockets in electrical connectors by indicating when proper pressure has been applied. It is used with circular pins, and indenters push into the pin from multiple. Power contact wall chart (m39029) updated: Web it lists the connector information, including part numbers, color code, pin/socket type, wire range and required crimp tool, accessory, and assembly tools for each size of power contact. The tool codes shown include crimp tools,. Web standard dmc power configuration these dimensions are consistent throughout this product line and will not be repeated. Our precision tooling has supported the defense and aerospace industries for over 75 years. The 8 impression crimp, which is standard in Web copper thermocouple pin #20: Web dmc power contact wall chart | pdf | electrical connector | electrical equipment. Insert tester (pin) into mating end of contact. Web copper thermocouple pin #20: In this example, the bin number is 260. Swage tooling quick start guide. Insert tester (pin) into mating end of contact. These tools check the retention of pins and sockets in electrical connectors by indicating when proper pressure has been applied. Our form crimp tools are capable of creating hexagonal, circular, nest and indent, b crimp, and captive crimps to name a few. [email protected] • www.dmctools.com cage code: Web dmc has worked closely with the world’s leading connector accessory manufacturers and standards organisations to develop the necessary tooling and accessories to meet the stringent demands of aerospace and defence system. Web it lists the connector information, including part numbers, color code, pin/socket type, wire range and required crimp tool, accessory, and assembly tools for each size of power contact. Refer to chart b for tip part numbers. A slightly more uncommon tool for hobbyists, but very common for industrial, military, automotive and aerospace purposes, is the pin crimping tool. The tool codes shown include crimp tools,. The 8 impression crimp, which is standard in Dmc power contact wall chart. Web refer to chart a for preset range of tool. Talk with us directly using livechat.

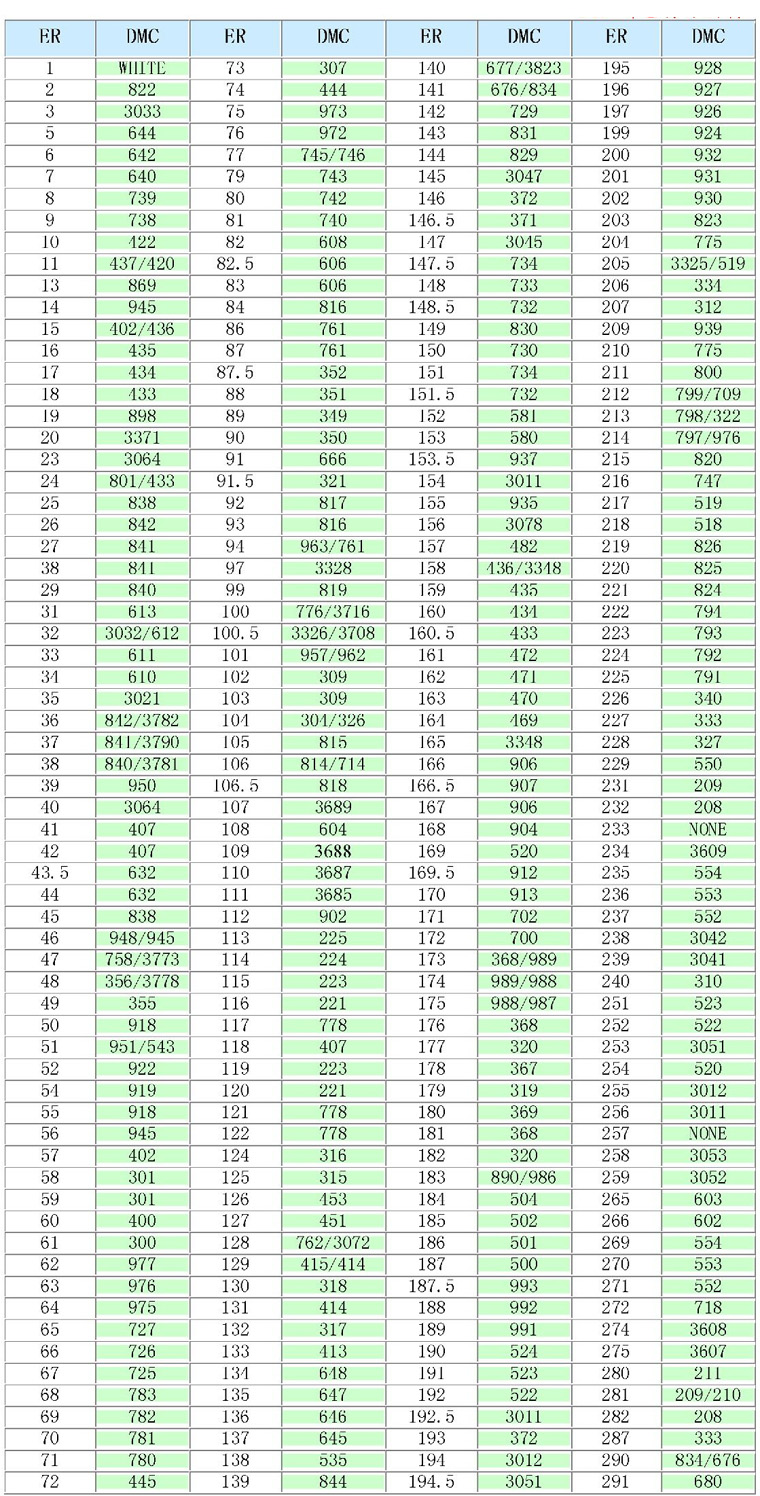

Dinky Dyes To Dmc Conversion Chart Konaka

Printable Dmc Thread Chart ubicaciondepersonas.cdmx.gob.mx

DMC Embroidery Floss Collection 35 New Colors Stitched Modern

:max_bytes(150000):strip_icc()/ConversionCharts_DMC-597a53dc9abed500108127aa.jpg)

Conversion Charts for Embroidery Thread and Floss

DMC color charts Needlework Pinterest

2 Piece Crimp Chart Mechanical Engineering

DMC Color Chart Updated Lord Libidan

Sulky Thread Conversion Chart To Dmc

Dmc Pin And Socket Chart Hot Sex Picture

Dmc Thread Color Conversion Chart

The Tester Tips Are Color Coded For Specific Sizes (Awg 4,

Each Tool Body Is Set For A Different Poundage Range (See Chart A On Back Of This Page).

Marking Includes Dmc Power Part Number And Tooling Swage Die Part Number Dmc Size Bus Size C Dia (O.d.) D Min.

Select Appropriate Tip And Screw Into Tool Body Through Slide.

Related Post: