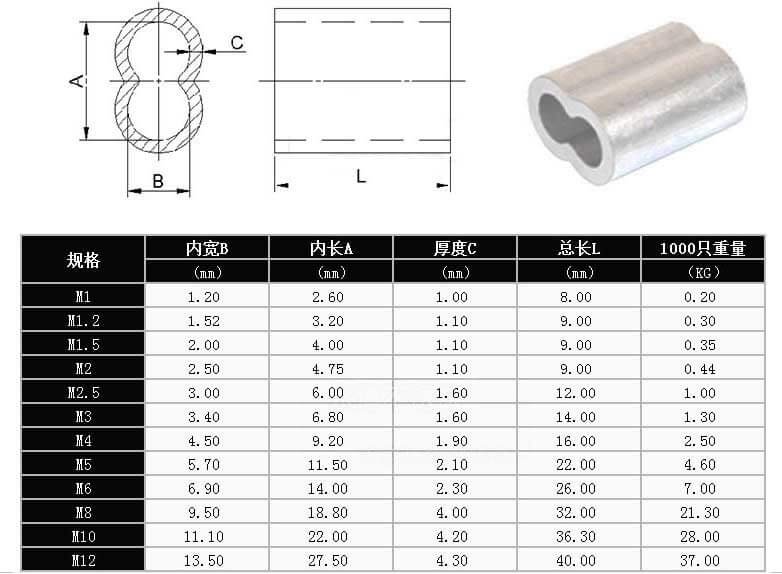

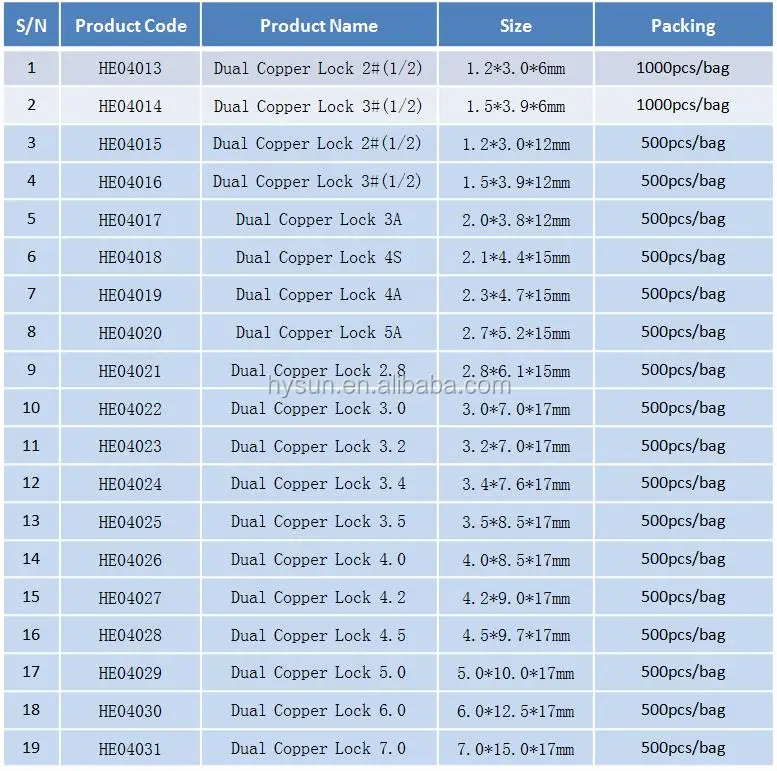

Crimping Sleeve Size Chart

Crimping Sleeve Size Chart - Tips and tricks for getting the perfect crimp every time. In addition to the sleeve material, it’s important to pick the right size to match your leader diameter. Insulated sleeves provide additional cable strain relief. Die size (mm2) listed awg awg equivalent in mm2. Your finished assembly should look as shown. Using the tolerances below it is possible to correct for this. Crimps are used mainly on heavier monofilament lines where they outperform bulky knots. Web te connectivity good crimping guide. Different sized sleeves will require a different number of swages. M, a, b, c, d, e, f, g, h, l. In addition to the sleeve material, it’s important to pick the right size to match your leader diameter. Avoid crimping near a sleeve edge. Different sized sleeves will require a different number of swages. Web select the appropriate crimp terminal based on the wire size and type, as well as the application. Web crimping sleeves come in two sizes: Electrical wire crimpers available on amazon canada tend to list die sizes in mm2. Both ends of the sleeve should be extended outside of the slot. Giant tuna & swordfish fishermen. Different sized sleeves will require a different number of swages. These are an excellent choice for serious anglers. Different sized sleeves will require a different number of swages. The long sleeves are better for heavier leaders and situations in which the crimp will not be visible, such as inside the skirt of a trolling lure or within a rigged bait. Avoid crimping near a sleeve edge. Web place the sleeve in the correct slot size of the crimper,. Web the soft metal and oval shape work together to provide a permanent crimp without compromising line strength. A wide variety of sizes coordinate for use with all lb. Web this chart shows the different crimp sizes for various types of fishing lines, helping you determine the right size for your line. * new short f & short g sleeves. Available in packages of 50 and 500. Web the soft metal and oval shape work together to provide a permanent crimp without compromising line strength. Crimps are used mainly on heavier monofilament lines where they outperform bulky knots. Web this chart shows the different crimp sizes for various types of fishing lines, helping you determine the right size for your. How to crimp your connections so they don't slip. Web the soft metal and oval shape work together to provide a permanent crimp without compromising line strength. To use the chart, check the diameter of your fishing line, and locate the corresponding crimp size in the chart. While cable leaders require brass or copper sleeves. Common mistakes to avoid when. They are available in various brass and copper alloys and in aluminium and you will need a cup to cup type crimp tool to compress them. Web what size crimp sleeve do i need? Insulated sleeves provide additional cable strain relief. Web place the sleeve in the correct slot size of the crimper, and make sure the sleeve is positioned. A wide variety of sizes coordinate for use with all lb. Web crimping sleeves come in two sizes: Die size (mm2) listed awg awg equivalent in mm2. Insulated sleeves provide additional cable strain relief. Crimps are used mainly on heavier monofilament lines where they outperform bulky knots. These are an excellent choice for serious anglers. Die size (mm2) listed awg awg equivalent in mm2. Electrical wire crimpers available on amazon canada tend to list die sizes in mm2. Insulated sleeves provide additional cable strain relief. Use the campbell “crimp chart” and only campbell manufactured components for safe and reliable hose performance. The long sleeves are better for heavier leaders and situations in which the crimp will not be visible, such as inside the skirt of a trolling lure or within a rigged bait. Web crimpnology, created by campbell, refers to the methodology of crimping sleeves or ferrules designed specifically to fit onto specific campbell fittings and couplings to a precisely calculated. Next article » manufactured in japan using strict quality assurance procedures to produce a high quality, burr free, precise fitting sleeve every time. Be sure to leave a small space in between each of the crimps. These charts from beadalon help you choose a crimp bead or crimp tube size based on the diameter of. Web the crimp dimensions can be affected by the manufacturing tolerances of the hose; M, a, b, c, d, e, f, g, h, l. Both ends of the sleeve should be extended outside of the slot. Using the tolerances below it is possible to correct for this. Crimp sleeves come in a wide range of sizes and materials. Choose the right crimping sleeve. This guide has been produced to help you achieve a perfectly crimped terminal or splice every time. In addition to the sleeve material, it’s important to pick the right size to match your leader diameter. In the case of this ¼” sleeve, it requires 4 swage crimps. Correct tooling for terminal and wire. Tips and tricks for getting the perfect crimp every time. Web select the appropriate crimp terminal based on the wire size and type, as well as the application. This style is in almost universal use on commercial longline vessels, and they catch some pretty big fish using them.

315Pcs 8 Sizes Aluminum Crimping Loop Sleeve Double Barrel Ferrule for

Crimp Sleeve Size Chart

Crimping selection Page 2 The Hull Truth Boating and Fishing Forum

Nicopress Crimping Tools Bloodydecks

Crimp Sleeve Size Chart

Brass Ferrule Crimper Hose and Fittings Source

Crimping Sleeve Size Chart

Crimping selection The Hull Truth Boating and Fishing Forum

Crimp Sleeve Size Chart

Leader Rigging Sports & Outdoors Single Barrel Sleeves for Leader

Additional Tips For Crimping Fishing Wire.

How To Crimp Your Connections So They Don't Slip.

Web For Each Sleeve Size, There Is A Prescribed Number Of Swage Crimps That Must Be Made.

Avoid Crimping Near A Sleeve Edge.

Related Post: