Control Charts Six Sigma

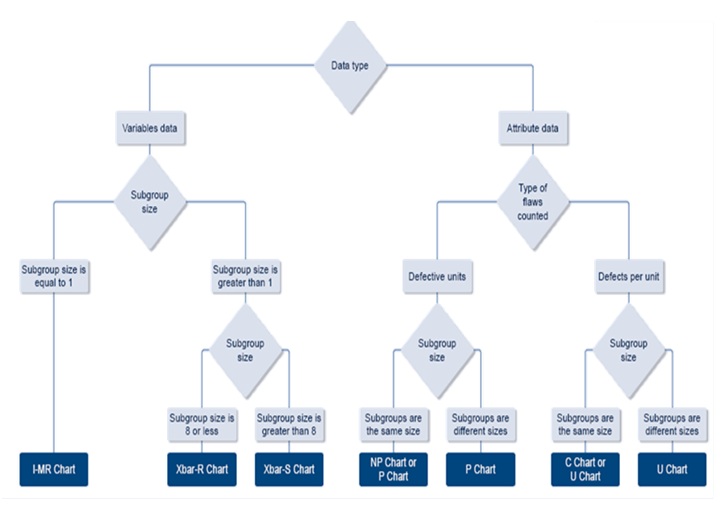

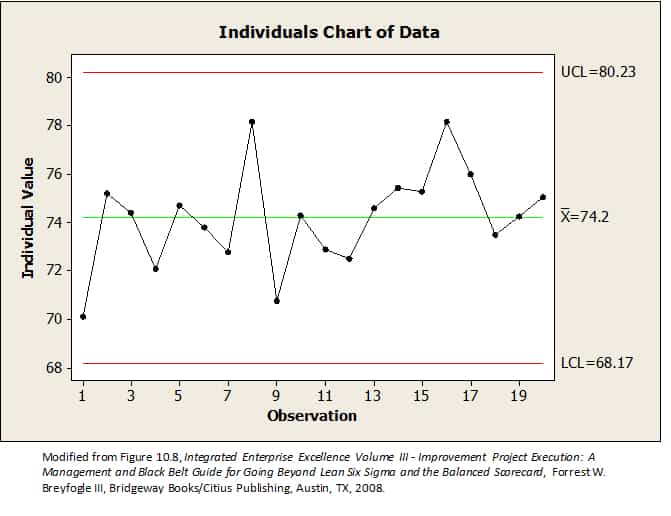

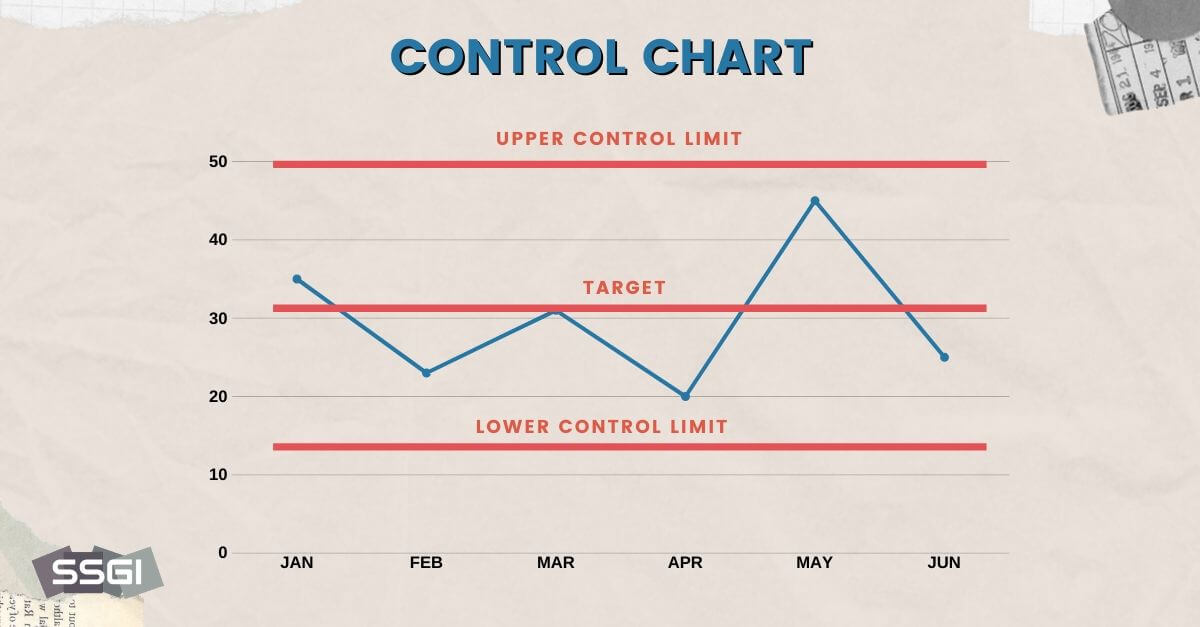

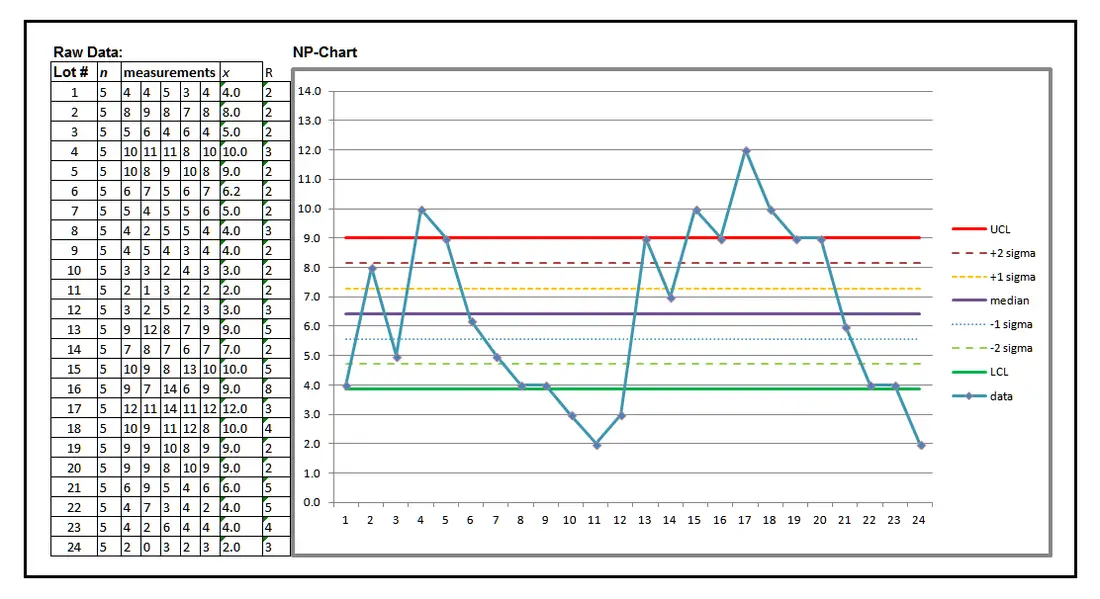

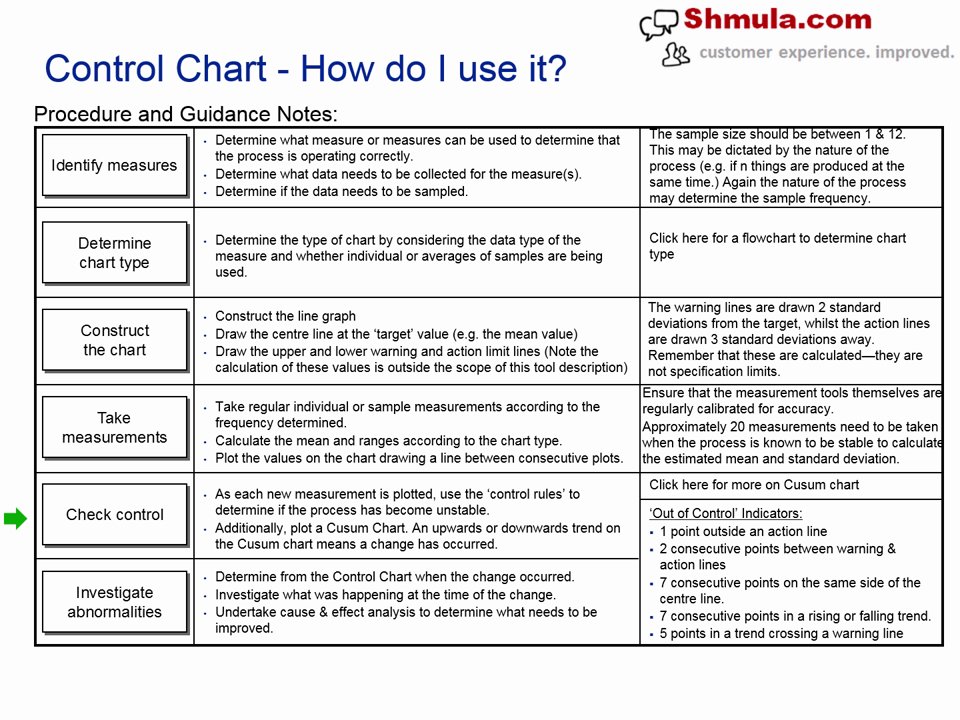

Control Charts Six Sigma - These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. When controlling ongoing processes by finding and correcting problems as they occur. Web this is where cusum charts truly excel, offering several key advantages: When determining whether a process is stable (in statistical control) Besides that, i noticed that there were a lot of different types of control charts. Control charts are the basis of statistical process controls methodologies, and are used to distinguish between random/uncontrollable variations and controlled/correctable variations in a system. When to use a control chart. Special cause variation, as distinct from common cause variation, refers to changes in process performance due to sporadic or rare events indicating that a. In the control chart, these tracked measurements are visually compared to decision limits calculated from probabilities of the actual process performance. By this, we can see how is the process behaving over the period of time. Web the primary statistical process control (spc) tool for six sigma initiatives is the control chart — a graphical tracking of a process input or an output over time. By this, we can see how is the process behaving over the period of time. Proactively find and remove potential errors throughout the design technique. Multiple user discountperpetual licensefree new buildspc. Besides that, i noticed that there were a lot of different types of control charts. Web control charts are a reliable and useful method to use as part of a strategy to identify the deterioration of natural processes. We can also call it as process behavior chart. Process behavior chart is another name for it. When controlling ongoing processes by. They help you measure and track process performance, identify potential problems, and determine corrective actions. Shewhart invented the control chart, it is often referred to as the shewhart chart. Different types of control charts serve different purposes based on the process parameters being measured and the data being collected. Web the following are the primary objectives of design for six. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Web the following are the primary objectives of design for six sigma (dfss): While studying for the six sigma black belt exam, i noticed many questions on the control charts. Donald wheeler, or shewhart charts by some. Web known as process behavior charts, control charts, and. Special cause variation, as distinct from common cause variation, refers to changes in process performance due to sporadic or rare events indicating that a. Web control charts are among the hardest things to understand for those studying six sigma. A time series graph is the starting point for a control map.. Web an ultimate guide to control charts in six sigma. They help you measure and track process performance, identify potential problems, and determine corrective actions. When controlling ongoing processes by finding and correcting problems as they occur. A control chart is also known as the shewhart chart since it was introduced by walter a shewhart. Special cause variation, as distinct. They help you measure and track process performance, identify potential problems, and determine corrective actions. Besides that, i noticed that there were a lot of different types of control charts. Web control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. Special cause variation, as distinct from common cause variation, refers to changes. Web an ultimate guide to control charts in six sigma. When predicting the expected range of outcomes from a process. Shewhart invented the control chart, it is often referred to as the shewhart chart. Here’s an easy control charts study guide for you. Control charts are the basis of statistical process controls methodologies, and are used to distinguish between random/uncontrollable. Web the following are the primary objectives of design for six sigma (dfss): Web the primary statistical process control (spc) tool for six sigma initiatives is the control chart — a graphical tracking of a process input or an output over time. Here’s an easy control charts study guide for you. Web this is where cusum charts truly excel, offering. By this, we can see how is the process behaving over the period of time. Shewhart invented the control chart, it is often referred to as the shewhart chart. We can also call it as process behavior chart. Proactively find and remove potential errors throughout the design technique. Web what is control charts in six sigma and how to create. The control chart is a tool used to distinguish between assignable (special) and random (common) kinds of variation. When predicting the expected range of outcomes from a process. Web control charts are a key tool used in the six sigma methodology. Web an ultimate guide to control charts in six sigma. Proactively find and remove potential errors throughout the design technique. Multiple user discountperpetual licensefree new buildspc and mac Web control charts are crucial six sigma tools that help organizations monitor processes, identify variations, and drive improvements. In the control chart, these tracked measurements are visually compared to decision limits calculated from probabilities of the actual process performance. Web what is control charts in six sigma and how to create them? By carefully understanding and considering client requirements, ensure that processes and products meet or surpass customer expectations. Here’s an easy control charts study guide for you. A control chart has three main components. While studying for the six sigma black belt exam, i noticed many questions on the control charts. Control charts are the basis of statistical process controls methodologies, and are used to distinguish between random/uncontrollable variations and controlled/correctable variations in a system. Web control charts are time charts designed to display signals or warnings of special cause variation. When to use a control chart.

What is Control Charts in Six Sigma and How to Create them?

6 Sigma Control Chart Introduction Toolkit from Leanscape

Six Sigma DMAIC Process Control Phase Control Chart Selection

Six Sigma

Control Charts Six Sigma

Six Sigma Control Charts

Lean Six Sigma The Definitive Guide (2020) SSGI

Statistical Process Control Charts Process Variation Measurement and

6 Sigma Control Chart Introduction Toolkit from Leanscape

Control Chart Rules Six Sigma A Visual Reference of Charts Chart Master

Web The Primary Statistical Process Control (Spc) Tool For Six Sigma Initiatives Is The Control Chart — A Graphical Tracking Of A Process Input Or An Output Over Time.

Control Charts Are An Essential Tool Used In Six Sigma To Monitor Process Stability And Improve Quality.

They Help You Measure And Track Process Performance, Identify Potential Problems, And Determine Corrective Actions.

Web Control Charts Are The Most Commonly Used Tools Of Statistical Quality Control To Assess If A Process Is In Control Or Not.

Related Post: