Control Chart Variables

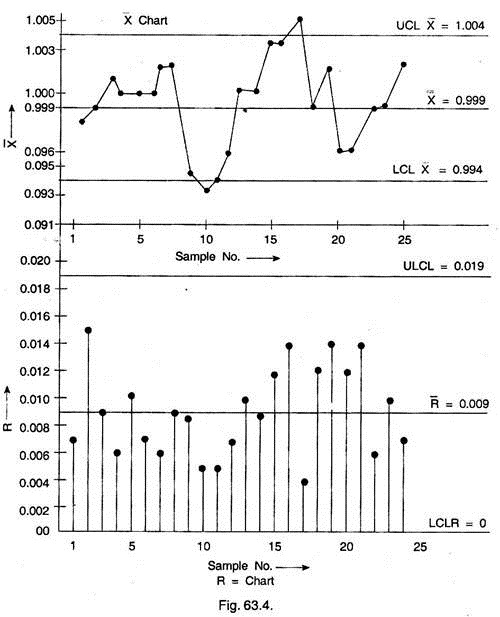

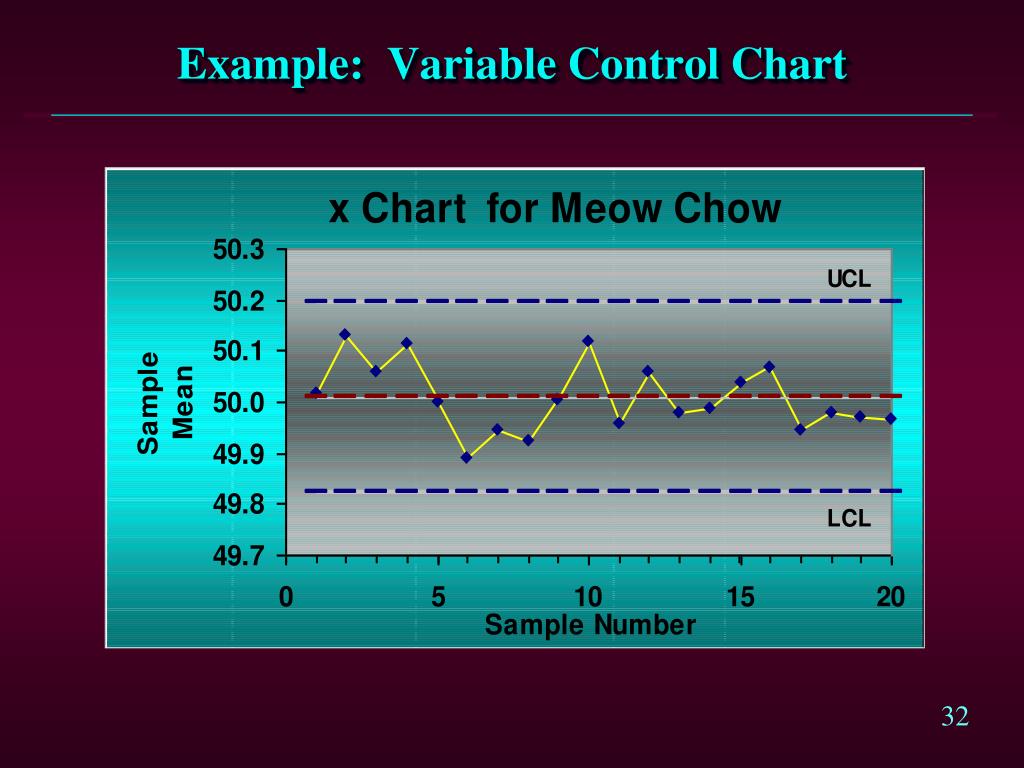

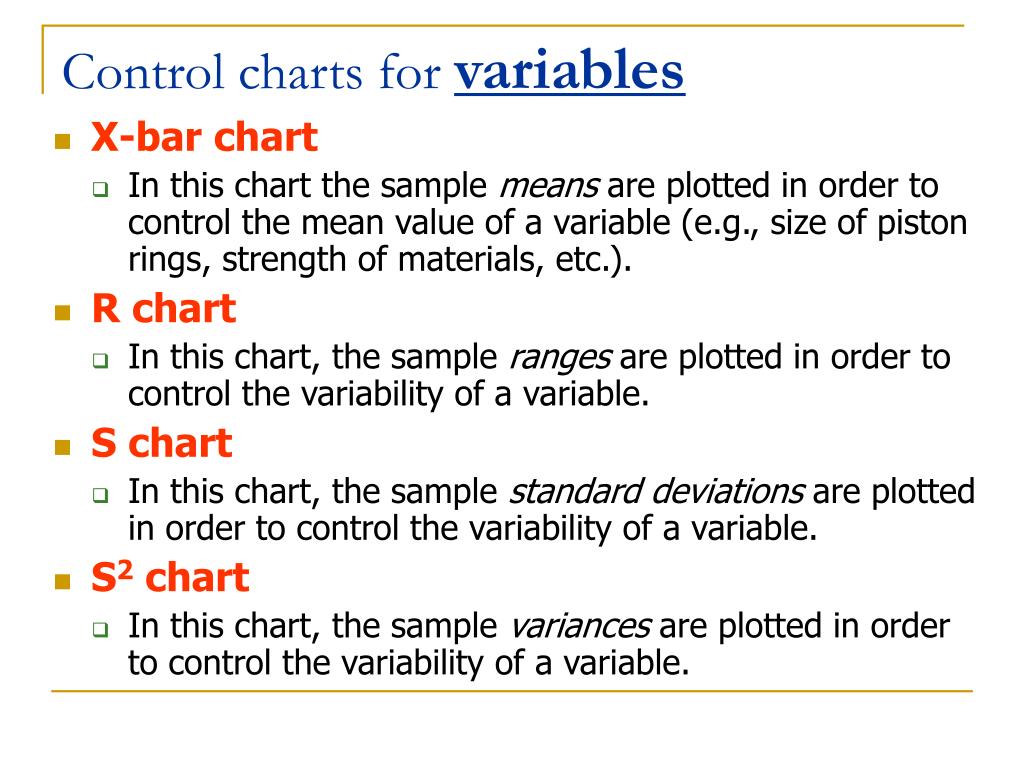

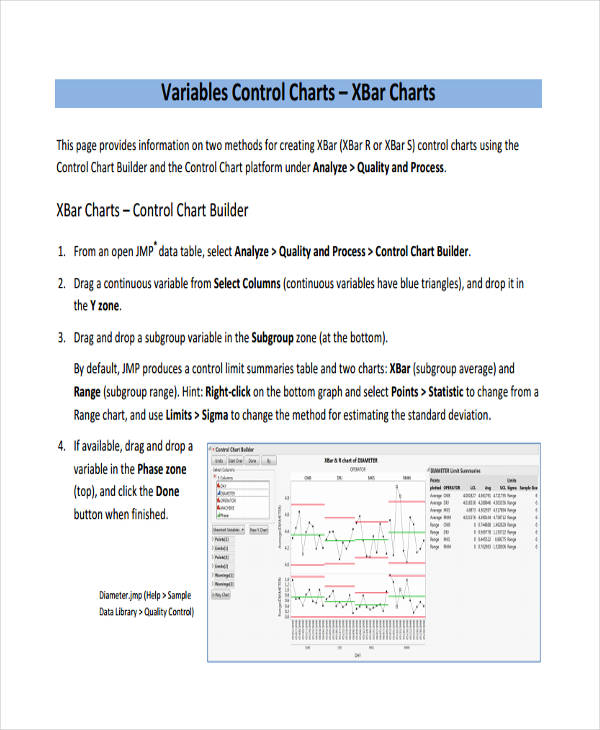

Control Chart Variables - These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Understand the concept of the control chart method. Standard deviation or σ chart. Web control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. Web control charts stand as a pivotal element in the realm of statistical process control (spc), a key component in quality management and process optimization. Web control charts are most frequently used for quality improvement and assurance, but they can be applied to almost any situation that involves variation. The center line represents the process mean. The minitab assistant includes two of the most widely used control charts for continuous data: Web control charts for variables. Web control charts are graphs that display the value of a process variable over time. Let \ (w\) be a sample statistic that measures some continuously varying quality characteristic of interest (e.g., thickness), and suppose that the mean of \ (w\) is \ (\mu_w\), with a standard deviation of \ (\sigma_w\). Web there are two types of control charts: Understand the concept of the control chart method. Control charts are also known as shewhart charts.. The center line represents the process mean. Let \ (w\) be a sample statistic that measures some continuously varying quality characteristic of interest (e.g., thickness), and suppose that the mean of \ (w\) is \ (\mu_w\), with a standard deviation of \ (\sigma_w\). Common cause variation is also known as the noise of the process. The bottom chart monitors the. Web variables control charts (those that measure variation on a continuous scale) are more sensitive to change than attribute control charts (those that measure variation on a discrete scale). Web what is a variables control chart? A stable process operates within an ordinary, expected range of variation. The center line represents the process mean. The problem is, my script is. It presents a graphic display of process stability or instability over. Web variable control charts contribute to quality improvement in healthcare by enabling visualization and monitoring of variations and changes in healthcare processes. Know the three categories of variation and their sources. So i thought it would make more sense to define. Standard deviation or σ chart. Web shewhart control charts for variables. Web control charts are simple but very powerful tools that can help you determine whether a process is in control (meaning it has only random, normal variation) or out of control (meaning it shows unusual variation, probably due to a special cause). Web variable control charts contribute to quality improvement in healthcare by enabling. Most control charts include a center line, an upper control limit, and a lower control limit. Web variables control charts (those that measure variation on a continuous scale) are more sensitive to change than attribute control charts (those that measure variation on a discrete scale). Before any control chart is introduced, however, there are certain basic requirements which have to. The center line represents the process mean. This chapter looks at the details of control charts for variables—quality characteristics that are measurable on a numerical scale. Common cause variation is also known as the noise of the process. Web control charts for variable data are used in pairs. Know the three categories of variation and their sources. Web control charts for variables are of three types: R charts are used to control the variability in process. Control charts are used to regularly monitor a process to determine whether it is in control. It presents a graphic display of process stability or instability over. A control chart, also known as a statistical process control chart, is a statistical. These charts offer a visual representation of process performance over time, plotting measured data points to track variations, identify abnormalities, and discern trends. Web control charts for variables. Web control charts are most frequently used for quality improvement and assurance, but they can be applied to almost any situation that involves variation. Most control charts include a center line, an. Most control charts include a center line, an upper control limit, and a lower control limit. Web variable control charts contribute to quality improvement in healthcare by enabling visualization and monitoring of variations and changes in healthcare processes. The control limits represent the process variation. A control chart, also known as a statistical process control chart, is a statistical tool. The problem is, my script is 5000 lines long and runs slower than molasses in a freezer. Web control charts are graphical plots used in production control to determine whether quality and manufacturing processes are being controlled under stable conditions. Web control charts for variable data are used in pairs. This chapter will cover the most commonly used control chart for variables: A control chart, also known as a statistical process control chart, is a statistical tool used to monitor, control, and improve the quality of processes. Web variables control charts (those that measure variation on a continuous scale) are more sensitive to change than attribute control charts (those that measure variation on a discrete scale). Web control charts help prevent overreactions to normal process variability while prompting quick responses to unusual variation. The main steps are as follows: A stable process operates within an ordinary, expected range of variation. Know the three categories of variation and their sources. Web control charts for variables. Control charts are used to regularly monitor a process to determine whether it is in control. Common cause variation is the variation inherent in the process. Know the purpose of variable control charts. A process with only common cause variation is highly predictable. Web control charts are simple but very powerful tools that can help you determine whether a process is in control (meaning it has only random, normal variation) or out of control (meaning it shows unusual variation, probably due to a special cause).

Control Charts for Variables and Attributes Quality Control

PPT Chapter 17 PowerPoint Presentation, free download ID5953193

PPT Control Charts for Variables PowerPoint Presentation, free

Control Chart A Key Tool for Ensuring Quality and Minimizing Variation

Control Chart Types

Types of Control Charts Statistical Process Control.PresentationEZE

PPT Control Charts for Variables PowerPoint Presentation, free

Control Chart 6+ Examples, Format, How to Make, Pdf

Control Charts For Variables YouTube

Control Chart 6+ Examples, Format, How to Make, Pdf

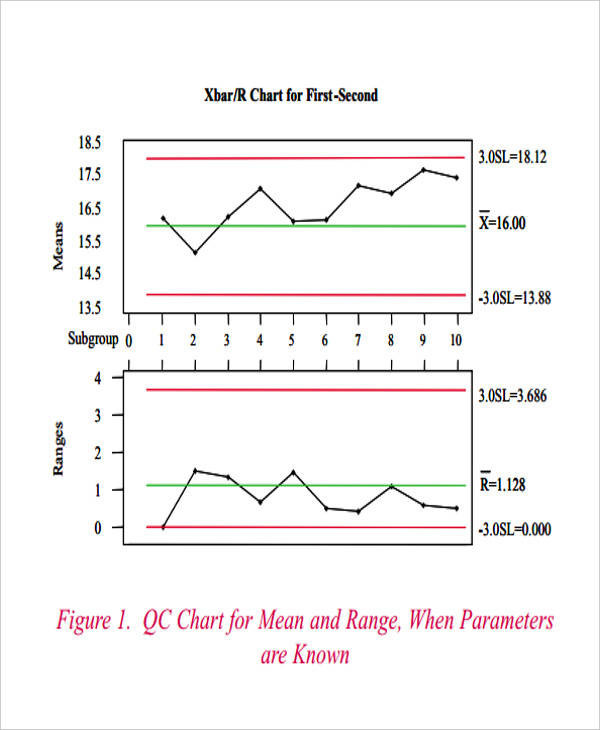

The Top Chart Monitors The Average, Or The Centering Of The Distribution Of Data From The Process.

Common Cause Variation Is Also Known As The Noise Of The Process.

Web A Control Chart Is A Statistical Tool Used To Distinguish Between Variation In A Process Resulting From Common Causes And Variation Resulting From Special Causes.

This Chapter Looks At The Details Of Control Charts For Variables—Quality Characteristics That Are Measurable On A Numerical Scale.

Related Post: