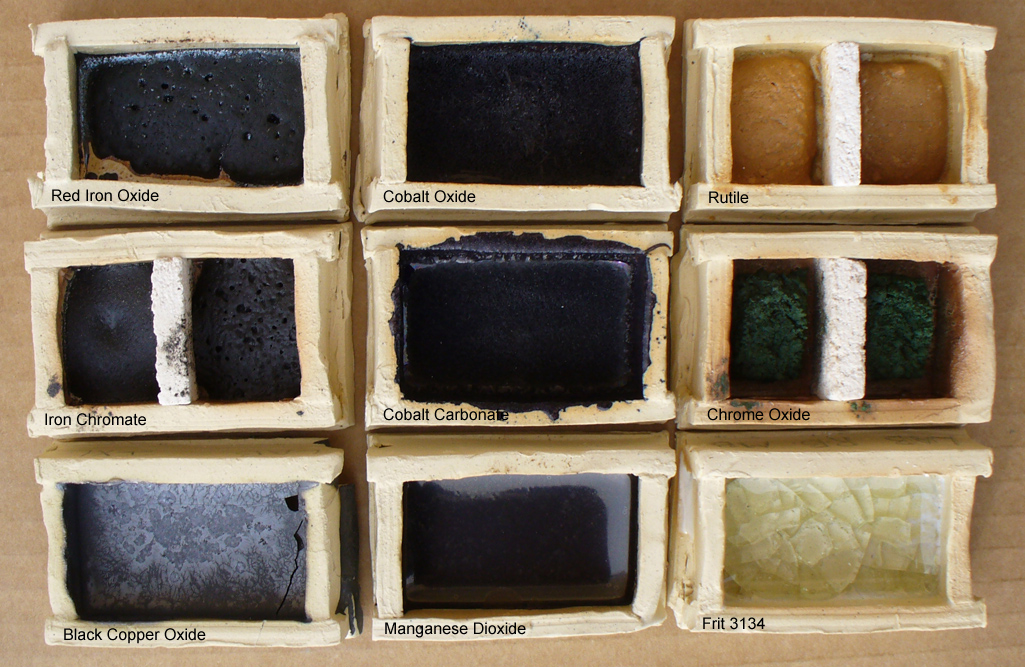

Ceramic Oxide Color Chart

Ceramic Oxide Color Chart - To get more uniform colors mix well. By combining ceramic oxides, ceramic stains, and ceramic pigments in various proportions, you can get every color in the spectrum. Ceradyne and ceramic industry disclaim any and all liability from error, omissions or inaccuracies in the above chart. Varying the amounts will give a variety of pinks to deep burgundy colors. It is a low temperature low expansion equivalent of silica. Web coloring metals increment chart. Learn about pottery glaze colorants, the colors they produce, and the factors that affect each of them, from composition to how they are fired. Alumina represents the most commonly used ceramic material in industry. They can be used to flux, form glass, and add color to pottery. Brush oxides on greenware, bisque and/or glaze. Black nickel oxide, cobalt oxide, copper carbonate, chrome oxide, iron chromate, manganese dioxide, red iron oxide, rutile, and yellow ochre. Oxides are binary compounds made up of oxygen and another element, usually a metal. There is a direct relationship between fired glaze properties (e.g. Under 1% can result in a green celadon color with traces of iron oxide in reduction.. Carbonates and oxides of certain metals, characterize most colorants including the commonly used cobalt carbonate, cobalt oxide, chrome. Melting range, gloss, thermal expansion, hardness, durability, color response, etc) and its oxide formula. Different oxides, such as copper oxide, cobalt oxide, and iron oxide, can produce a wide range of colors when incorporated into glazes. Varying the amounts will give a. You should note that tests with cobalt oxide and chrome oxide in high percentages were not executed due to the color predictability. Web common ceramic oxides al 2 o 3 | b 2 o 3 | bao | c | cao | co 2 | coo | cr 2 o 3 | cu 2 o | cuo | fe 2. Varying the amounts will give a variety of pinks to deep burgundy colors. Common metal oxide materials are iron oxide, cobalt oxide, chrome oxide, copper oxide, manganese dioxide Ceramic colorants are added to a glaze or a clay to create color. It has a low expansion and high melting temperature. Web here are the top 10 ways to experiment with. Web contact your component supplier for more detailed information. Different oxides, such as copper oxide, cobalt oxide, and iron oxide, can produce a wide range of colors when incorporated into glazes. You should note that tests with cobalt oxide and chrome oxide in high percentages were not executed due to the color predictability. Web the most common glazes used in. Metallic oxides can have different colors before and after firing. A guide to using ceramic colorants,ceramic stains, and ceramic oxides, you'll find a little help to better understand what, how, and why ceramic colorants work in a glaze. There is a direct relationship between fired glaze properties (e.g. Varying the amounts will give a variety of pinks to deep burgundy. Web the most common glazes used in pottery are a composite of a base transparent with a metal oxide added to color it (with optional opacifier and variegator). Can be added to glaze, underglaze, slips, or directly to clay bodies for color and other properties. Gives red, coral and yellow colors. Manufactured from a mix of metallic and ceramic oxides,. Make some slip and add some oxides to create colors. Web metal oxides are what the name suggests. Web it combines well with silica and basic oxides to give body, durability, and stability to glazes. Web pigments provide a wide range of color possibilities in clay bodies, inglazes, underglazes, and onglazes. Common metal oxide materials are iron oxide, cobalt oxide,. Web it combines well with silica and basic oxides to give body, durability, and stability to glazes. Remember that these are targets that should help you, but you can get red colors to develop with less amounts of tin oxide (see cranberry glaze with 3.5% tin oxide). Carbonates and oxides of certain metals, characterize most colorants including the commonly used. Ceramic colorants are added to a glaze or a clay to create color. Web contact your component supplier for more detailed information. What is the use of “calculating” a glaze? Varying the amounts will give a variety of pinks to deep burgundy colors. Oxides are binary compounds made up of oxygen and another element, usually a metal. Black nickel oxide, cobalt oxide, copper carbonate, chrome oxide, iron chromate, manganese dioxide, red iron oxide, rutile, and yellow ochre. Common metal oxide materials are iron oxide, cobalt oxide, chrome oxide, copper oxide, manganese dioxide Ceramic colorants are added to a glaze or a clay to create color. To get more random, blotchy colors, don’t mix too well. Carbonates and oxides of certain metals, characterize most colorants including the commonly used cobalt carbonate, cobalt oxide, chrome. Ceradyne and ceramic industry disclaim any and all liability from error, omissions or inaccuracies in the above chart. Varying the amounts will give a variety of pinks to deep burgundy colors. Web ceramic stains are a mixture of ceramic oxides and coloring metal oxides that are melted in kilns, quenched, ground to specific mesh size (some are acid washed), and colored with organic dyes to simulate the fired color. Web ceramic colorants and combinations to choose from. If added to an effect glazes, stunning effects are produced. Web contact your component supplier for more detailed information. Make some slip and add some oxides to create colors. Manufactured from a mix of metallic and ceramic oxides, often with added coloring dyes. Brush oxides on greenware, bisque and/or glaze. In order to get a full range of consistent ceramic colors, pigments are used with metallic oxides and salts, many of which are soluble or toxic, to make them stable. You should note that tests with cobalt oxide and chrome oxide in high percentages were not executed due to the color predictability.

Ceramic oxide CoO Cobalt Oxide

Ceramic Oxide Color Chart

_0017_Butterfield Select Grade Oxide Colour Chart ConSpec Industries

Ceramics WG Ball

Ceramica

Ceramic Oxide Color Chart JACOB RUSSELL

Oxide Add Mix Sydney Decorative Concretors Warehouse

Ceramic Oxide Color Chart

Ceramic Oxide Color Chart

Ceramic Oxide Color Chart JACOB RUSSELL

Web It Combines Well With Silica And Basic Oxides To Give Body, Durability, And Stability To Glazes.

By Combining Ceramic Oxides, Ceramic Stains, And Ceramic Pigments In Various Proportions, You Can Get Every Color In The Spectrum.

It Is A Low Temperature Low Expansion Equivalent Of Silica.

Can Be Added To Glaze, Underglaze, Slips, Or Directly To Clay Bodies For Color And Other Properties.

Related Post: