Bending Allowance Chart

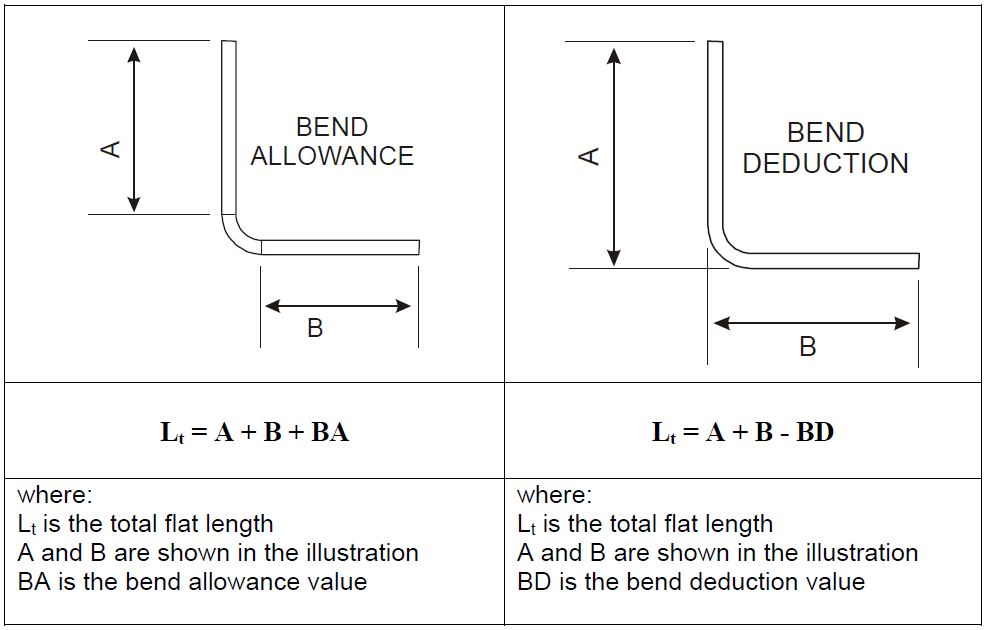

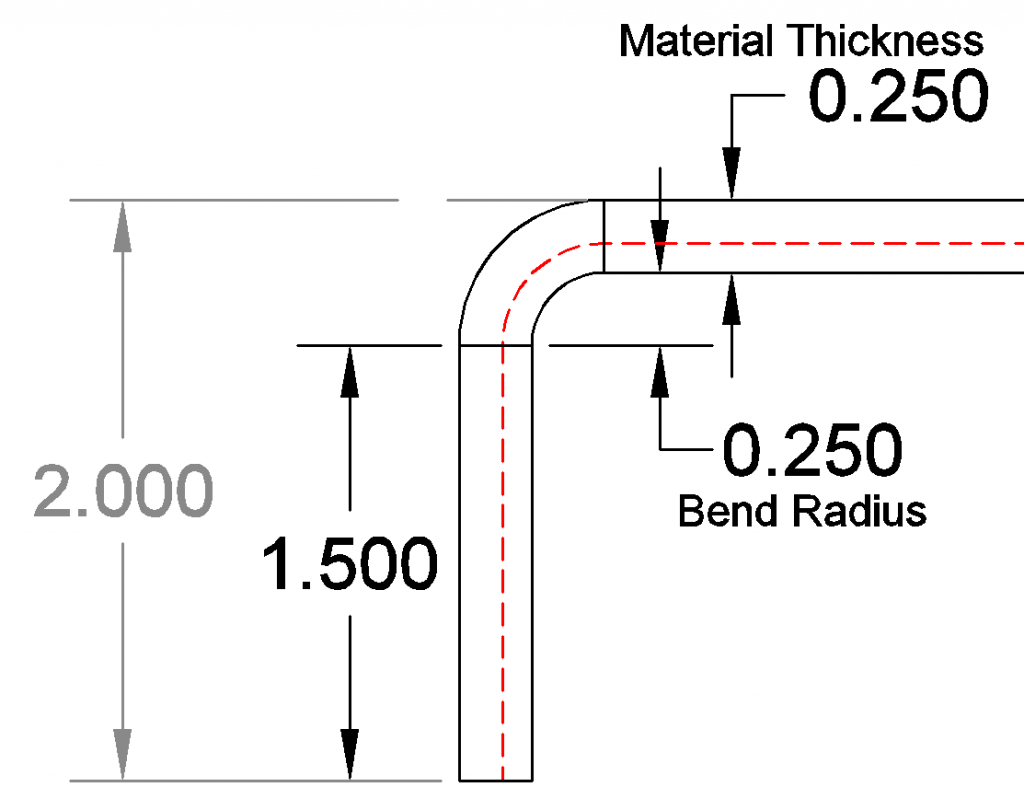

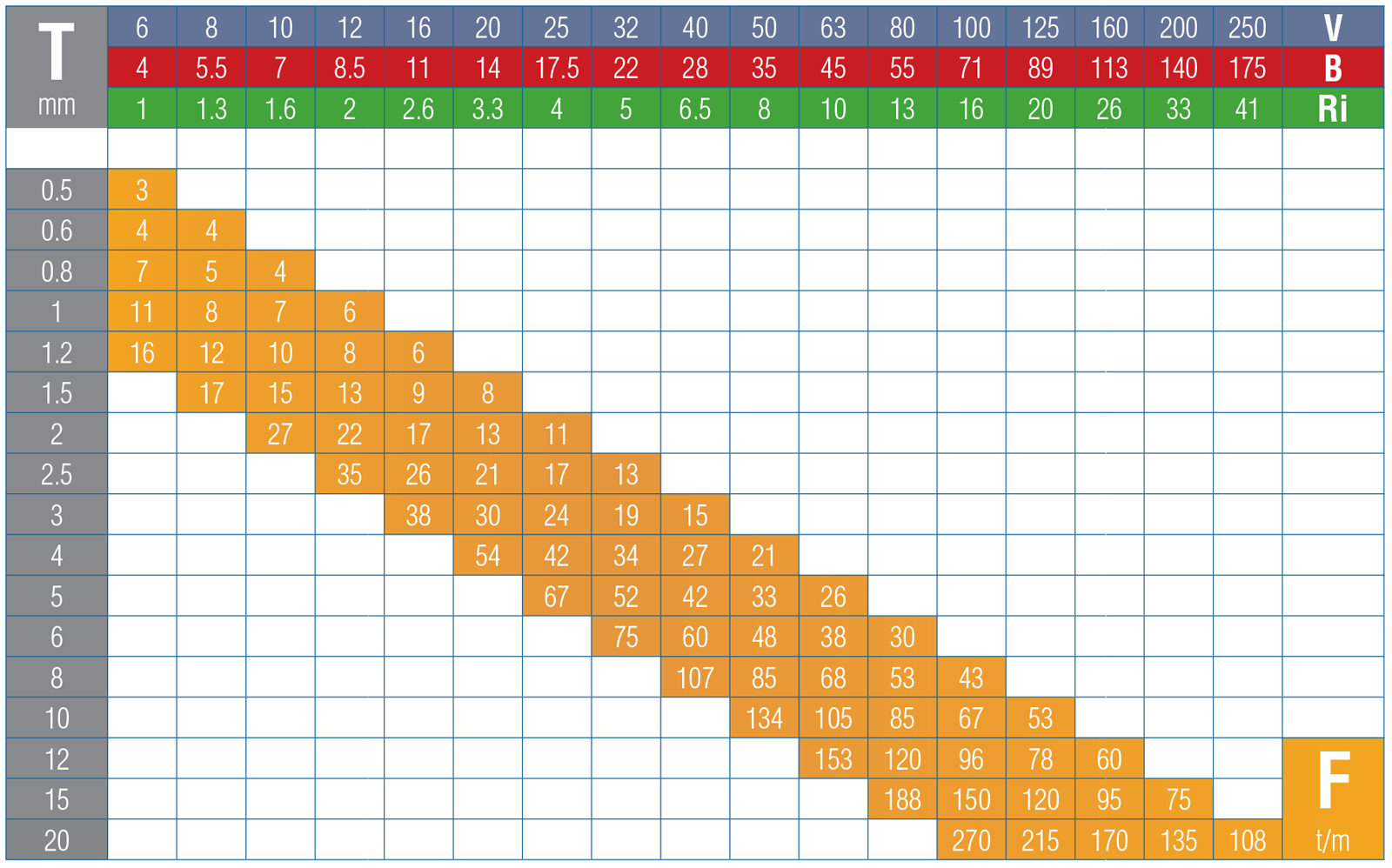

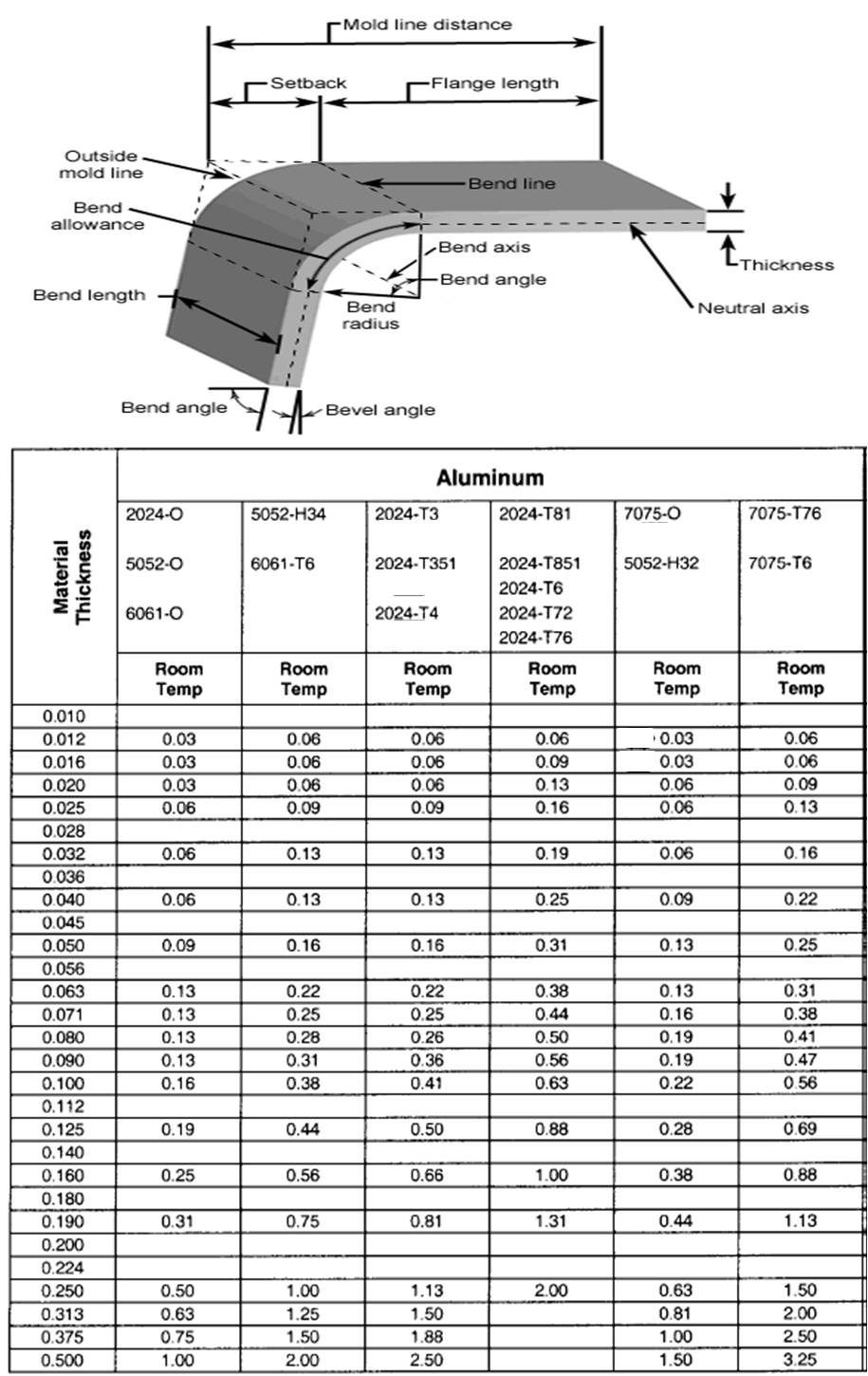

Bending Allowance Chart - Many will say material “grows” or “stretches” as it is bent in a press brake. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some allowance for the bend is taken into account. Identify the thickness of the material. The bending allowance table is a convenient resource that lists the thickness, bending radius, bending angle, bending allowance, or bending deduction values of common materials in a tabular format. Bending radius ir on the sheet metal. Web air bending force chart for stainless steel (rm≈700 n/mm2) considering material thickness (t) and die opening (v) the table below shows the most important bending data: Importance of accurate bend allowance calculation. Web the bend deduction method states that the flattened length (l) of a part is equal to the sum of the lengths of the two flat parts extending to the “cusp” (the point where the two flat parts intersect virtually) minus the bend. Minimum bendable flange length bmin. Web bend deduction charts. If you know the size of your flat material and want to calculate how long the flanges will be after bending, bend allowance is what you want. How bend allowance affects the overall dimensions. Bending radius ir on the sheet metal. (mild steel only) calculated bend allowances are approximate, not exact. The bending allowance table is a convenient resource that. Web air bending force chart for stainless steel (rm≈700 n/mm2) considering material thickness (t) and die opening (v) the table below shows the most important bending data: Identify the thickness of the material. It tells us how much extra length is generated by the bend deforming. Web bend allowance is the arc length of the neutral axis through the bend.. Web bend allowance is the arc length of the neutral axis through the bend. Ideal for professionals seeking efficient and accurate metal forming. The bending allowance table is a convenient resource that lists the thickness, bending radius, bending angle, bending allowance, or bending deduction values of common materials in a tabular format. Web the following illustration shows the equation /. This is defined as the length of the neutral fibre from the beginning to the end of the arc generated by the bend. The above formula is for right angle bends only. Web the bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance. Web featuring bend allowance charts. The bending allowance table is a convenient resource that lists the thickness, bending radius, bending angle, bending allowance, or bending deduction values of common materials in a tabular format. The above formula is for right angle bends only. It tells us how much extra length is generated by the bend deforming. For the most part, they varied widely. Web bend. Actual dimensions can only be found by making the bend and measuring the results. Many will say material “grows” or “stretches” as it is bent in a press brake. This is defined as the length of the neutral fibre from the beginning to the end of the arc generated by the bend. The final formed dimensions will be greater than. Most sheet metal materials will conform to the calculations. It tells us how much extra length is generated by the bend deforming. The above formula is for right angle bends only. The bending allowance table is a convenient resource that lists the thickness, bending radius, bending angle, bending allowance, or bending deduction values of common materials in a tabular format.. Minimum bendable flange length bmin. For the most part, they varied widely. Web when a sheet metal part is bent, it physically gets bigger. Web bend deduction charts. Web allowances for sheet metal air bends. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some allowance for the bend is taken into account. Actual dimensions can only be found by making the bend and measuring the results. Web the bend allowance formula takes into account the geometries of bending and the. Simply enter the dimensions of your project into the calculator, and it will calculate the bend allowance for you. Bending radius ir on the sheet metal. Web bend deduction charts. Web the following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Web our bend allowance calculator simplifies complex calculations, ensuring you understand the. The bend allowance (ba) represents the length of the flattened bend area. Press force f in kn / m. Simply enter the dimensions of your project into the calculator, and it will calculate the bend allowance for you. The bend allowance and bend deduction are essential parameters for achieving accurate results in press brake bending. Web featuring bend allowance charts for materials like cold rolled steel sheet (spcc), aluminum plates, and copper plates. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances. Importance of accurate bend allowance calculation. Web our bend allowance calculator simplifies complex calculations, ensuring you understand the importance and application of the formula in your fabrication tasks. How bend allowance affects the overall dimensions. Most sheet metal materials will conform to the calculations. Web bend deduction charts. Web the bending allowance algorithm describes the unfolded length (lt) of a sheet metal part as the sum of the lengths of each segment after the part is flattened, plus the length of the flattened bend area. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless some allowance for the bend is taken into account. Web bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Web the bend deduction method states that the flattened length (l) of a part is equal to the sum of the lengths of the two flat parts extending to the “cusp” (the point where the two flat parts intersect virtually) minus the bend. For the most part, they varied widely.

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory

Sheet Metal Minimum Bend Radius Chart

Bend Allowance ToolNotes

Bending Chart Tecnostamp srl

Bend Allowance Chart

Bend Allowance Calculator Mechanical Engineering Nature

Sheet Metal Bending Chart Labb by AG

Bend Allowance Metalworking Tools Free 30day Trial Scribd

Bending Tonnage Chart SAMS Fabrications

CI Bend Allowance Chart (AE103) Cincinnati Incorporated

This Information Is Stored In A Designated Location, Making It Easy To Access And Select When Needed.

It Tells Us How Much Extra Length Is Generated By The Bend Deforming.

Web Bend Allowance.xls Bend Allowance Chart

Bending Radius Ir On The Sheet Metal.

Related Post: