Belt Tension Chart

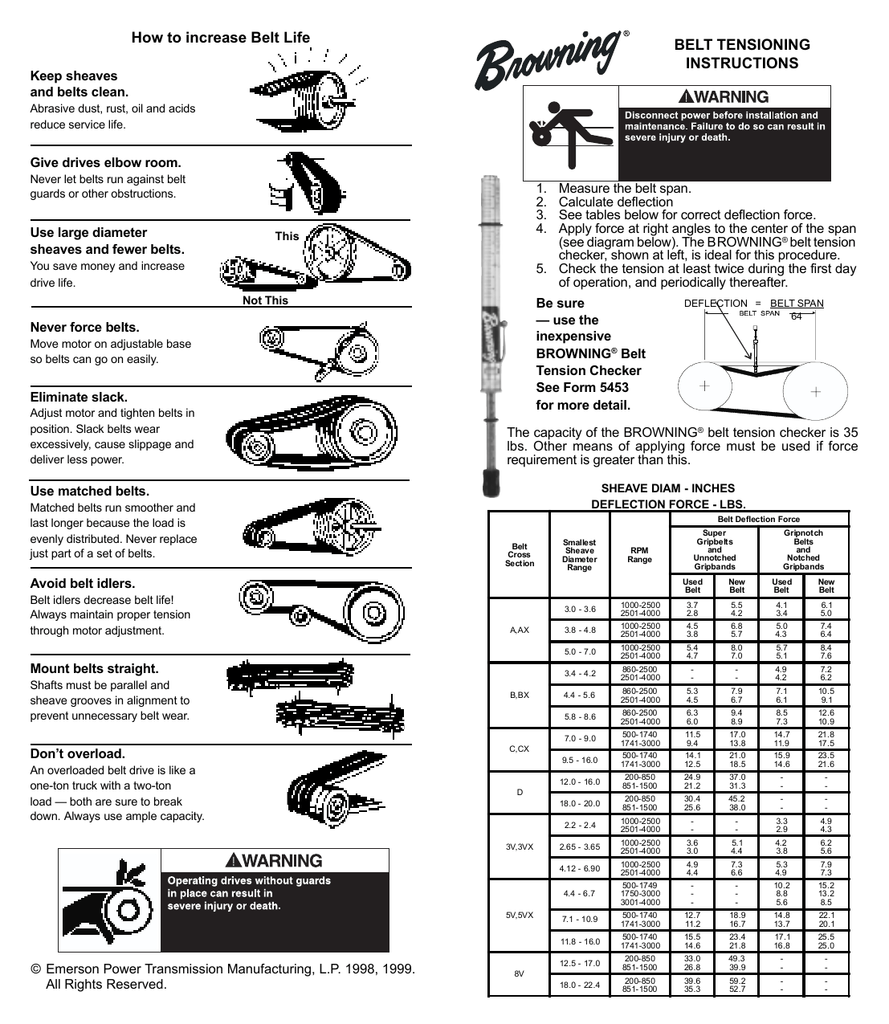

Belt Tension Chart - Te is the sum of the tension required to move the empty belt (tc), the tension required to. Ti ≈ 0.3 • b †t1all where: Web industrial belt identification chart. Te is the sum of the tension required to move the empty belt (tc), the tension required to move. (calculates the force exerted by an endless belt on a pulley, i.e., the force of two belt strands) we recommend stretching most unreinforced round belts at. Web jk fenner has developed an online calculator to simplify this for you. For comprehensive product information see gates industrial power transmission systems catalog no. Web it is desirable to calculate and measure belt tension based on drive loads. Be careful not to trap fingers ! Proper belt tensioning why it. Web target tension for a urethane flat belt: D = large pulley pitch diameter. Proper belt tensioning why it. This software can calculate the right belt section, size, belt tension and more based on details about the. Proper tension corresponding to the belt width can be. Proper tension corresponding to the belt width can be. Web industrial belt identification chart. (calculates the force exerted by an endless belt on a pulley, i.e., the force of two belt strands) we recommend stretching most unreinforced round belts at. D = small pulley pitch diameter. For automatic tensioner applications, no. Ideal tension is the lowest tension at. Te is the sum of the tension required to move the empty belt (tc), the tension required to. First, the effective belt tension (te) must be calculated. Web however, there is still a wide range of tension which a belt will operate satisfactorily. This is the preferred method of our customers. Ideal tension is the lowest tension at. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. For comprehensive product information see gates industrial power transmission systems catalog no. Web jk fenner has developed an online calculator to simplify this for you. Web install the belts to be a snug fit around the pulleys. Web jk fenner has developed an online calculator to simplify this for you. For automatic tensioner applications, no. Be careful not to trap fingers ! Te is the sum of the tension required to move the empty belt (tc), the tension required to. Detailed performance calculations in all variations with. Ideal tension is the lowest tension at. First, the effective belt tension (te) must be calculated. (calculates the force exerted by an endless belt on a pulley, i.e., the force of two belt strands) we recommend stretching most unreinforced round belts at. Proper tension per single belt can be calculated. For comprehensive product information see gates industrial power transmission systems. Web 1] install the belts to be a snug fit around the pulleys. Be careful not to trap fingers ! Web jk fenner has developed an online calculator to simplify this for you. First, the effective belt tension (te) must be calculated. Web industrial belt identification chart. Te is the sum of the tension required to move the empty belt (tc), the tension required to. D = large pulley pitch diameter. Web it is desirable to calculate and measure belt tension based on drive loads. Initial belt tension (lbs) for belts wider than 4 (100mm), use 80 lbs (356 n) thickness (inches). Web apply force at right. Web however, there is still a wide range of tension which a belt will operate satisfactorily. Proper belt tensioning why it. Proper belt tension ensures optimum performance of a vehicle's accessory belt drive system. Web apply force at right angles to the center of the span (see diagram below). The browning® belt tension checker, shown at left, is ideal for. For comprehensive product information see gates industrial power transmission systems catalog no. D = large pulley pitch diameter. 2] rotate the pulleys a few revolutions to allow the belts to sit correctly in the pulley grooves. (calculates the force exerted by an endless belt on a pulley, i.e., the force of two belt strands) we recommend stretching most unreinforced round. For automatic tensioner applications, no. The browning® belt tension checker, shown at left, is ideal for this procedure. Be careful not to trap fingers ! Te is the sum of the tension required to move the empty belt (tc), the tension required to move. First, the effective belt tension (te) must be calculated. Web 1] install the belts to be a snug fit around the pulleys. Web it is desirable to calculate and measure belt tension based on drive loads. Detailed performance calculations in all variations with. Select from the dropdown options below to find the. D = small pulley pitch diameter. This is the preferred method of our customers. Before beginning, inspect the timing belt for damage and verify that the. Web install the belts to be a snug fit around the pulleys. For comprehensive product information see gates industrial power transmission systems catalog no. Web jk fenner has developed an online calculator to simplify this for you. Web c = center distance.

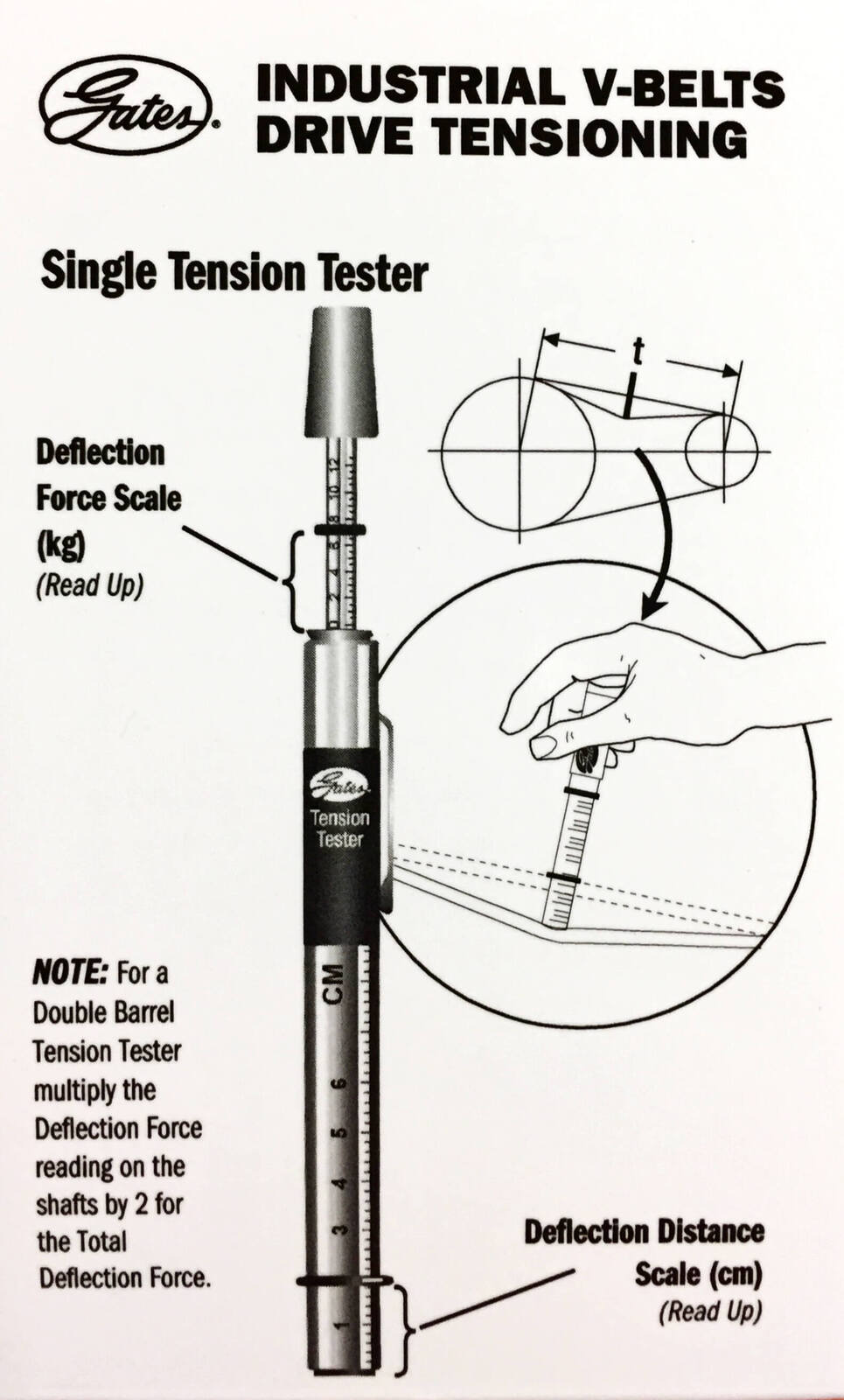

Gates Pocket VBelt Tension Guide

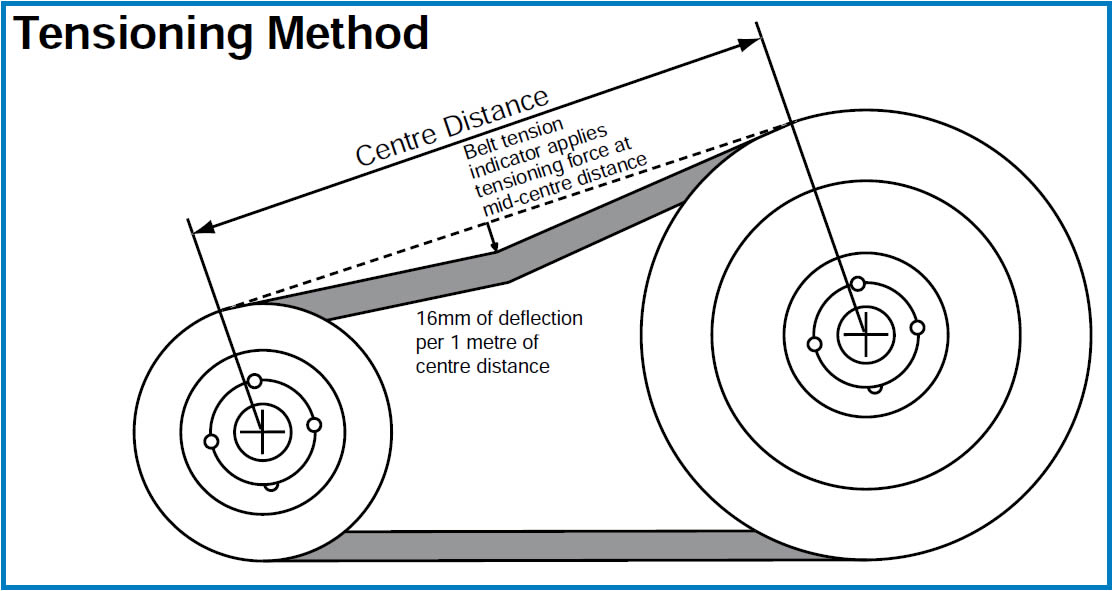

Belts Drives Belt Tensioning

Belts Drives Belt Tensioning

Fenner V Belt Tension Chart

V Belt Tension Gauge Chart

Belt Tensioning Chart

Belt Tension Chart PDF

Belt Tension Required Belt (Mechanical) Manufactured Goods

Belt Tension Chart PDF

Browning Belt Tensioning InstructionsForm 8082

2] Rotate The Pulleys A Few Revolutions To Allow The Belts To Sit Correctly In The Pulley Grooves.

Ti ≈ 0.3 • B †T1All Where:

This Software Can Calculate The Right Belt Section, Size, Belt Tension And More Based On Details About The.

Proper Belt Tension Ensures Optimum Performance Of A Vehicle's Accessory Belt Drive System.

Related Post: