Axle Spacing Chart

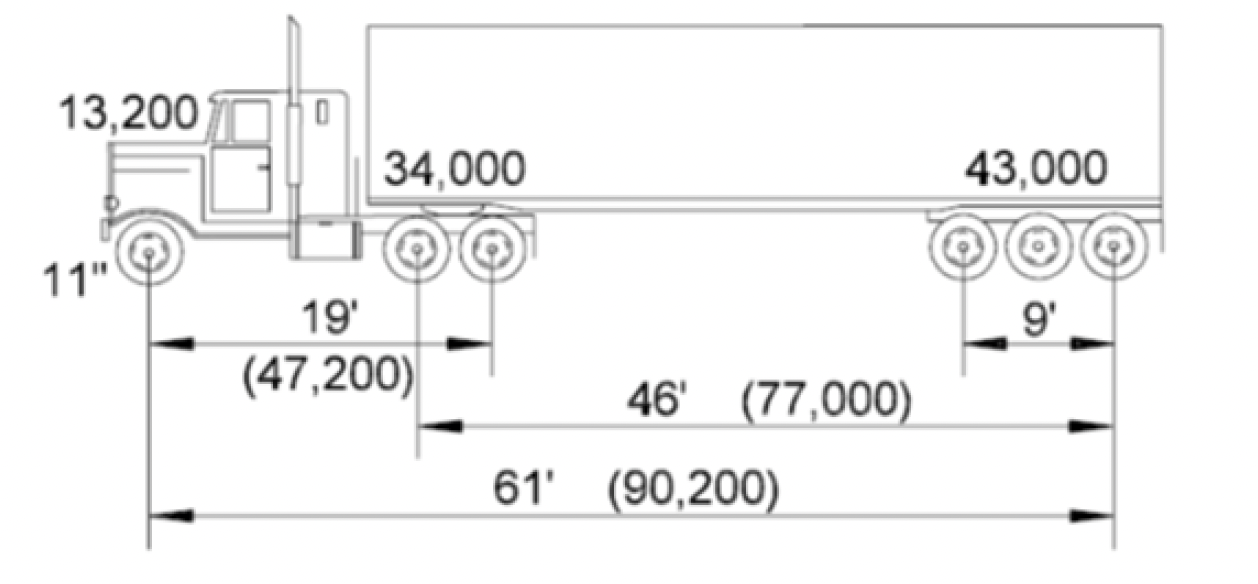

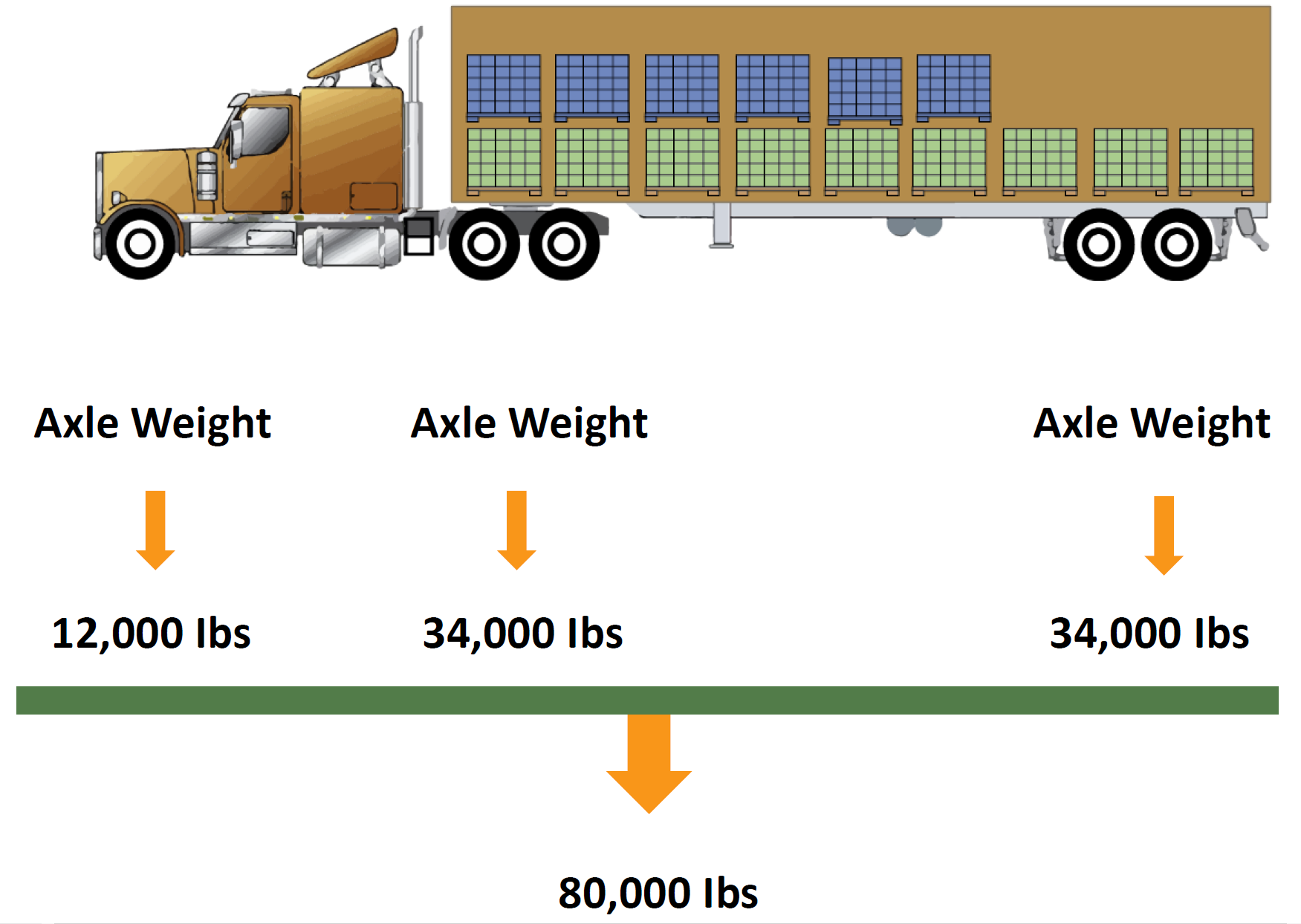

Axle Spacing Chart - Ideally your trailer should have 10 to 14. In this example, let’s say the wheelbase of the vehicle is 208 in. You don't actually need nearly this. Instead of centering your middle spring. Web the 60/40 axle placement formula is a great starting point and does take into account the tongue of the trailer from where the trailer sits on the hitch ball. Configure the optimal vehicle for your customer's needs. This is table 4—axle spacing. You will find this on the vehicle specification sheet. Web check your axle configuration. Learn how to calculate axle weight, why it matters, and how to get overweight permits. Ideally your trailer should have 10 to 14. W (actual weight) = 17,000 + 17,000 + 17,000 + 17,000 = 68,000 lb. For a dual axle, see ti sheet: Web check your axle configuration. You will find this on the vehicle specification sheet. 3,500 lb axles commonly have a 5 lug bolt pattern,. Please keep in mind that. Axles are essential components of any vehicle and come in three main types: Web this axle spacing is satisfactory. If your vehicle is overweight, you will need an axle spacing report number. Web a general rule of thumb is that 60 percent of the total trailer weight should be forward of the center line of the axle or axles on the trailer. Instead of centering your middle spring. Web this chart shows some of the most common heavy vehicle combinations used in australia. Web use the principles outlined for the axle placement. Hanger spacing is important, but you will also want to make sure that the axles are positioned. Web use the principles outlined for the axle placement on the tandem axle trailer to find the centerline of the axle on the single axle trailer. For a single axle, see ti sheet: For a dual axle, see ti sheet: W (actual weight). You will find this on the vehicle specification sheet. This is table 4—axle spacing. Web this axle spacing is satisfactory. Instead of centering your middle spring. Web how is axle hanger spacing measured? This can be entered in two different ways: For a dual axle, see ti sheet: Road train axle spacing mass limits. Axles are essential components of any vehicle and come in three main types: Axle spacing mass limits road train table. It is not a comprehensive representation of the entire australian heavy vehicle fleet and. In this example, let’s say the wheelbase of the vehicle is 208 in. Web how is axle hanger spacing measured? Fill in the axle weights in pounds in the. This is table 4—axle spacing. You don't actually need nearly this. Instead of centering your middle spring. Axles are essential components of any vehicle and come in three main types: Web the 60/40 axle placement formula is a great starting point and does take into account the tongue of the trailer from where the trailer sits on the hitch ball. Web this chart shows some. For a dual axle, see ti sheet: Web use the principles outlined for the axle placement on the tandem axle trailer to find the centerline of the axle on the single axle trailer. Web the 60/40 axle placement formula is a great starting point and does take into account the tongue of the trailer from where the trailer sits on. Web an axle is a rod or shaft that rotates the wheels and supports the weight of your vehicle. Web how is axle hanger spacing measured? Configure the optimal vehicle for your customer's needs. Web see diagram below. Web a general rule of thumb is that 60 percent of the total trailer weight should be forward of the center line. You will find this on the vehicle specification sheet. Web see diagram below. Feet with hundredths of a foot; Learn how to calculate axle weight, why it matters, and how to get overweight permits. For a dual axle, see ti sheet: Now check axles 2 through 5 using the illustration and table. Web this chart shows some of the most common heavy vehicle combinations used in australia. Get your axle spacing report number using the calculator on this page. Please keep in mind that. Full overview of our axle spacing and weight calculator. It is not a comprehensive representation of the entire australian heavy vehicle fleet and. Web use the principles outlined for the axle placement on the tandem axle trailer to find the centerline of the axle on the single axle trailer. Learn how to choose the right trailer axle for your needs based on suspension type, load capacity, mounting position, hub faces distance, track width, bolt patter… Web a general rule of thumb is that 60 percent of the total trailer weight should be forward of the center line of the axle or axles on the trailer. Instead of centering your middle spring. Web the distance between the center of the axles should be between 33 and 35 inches.

Truck Bridge Axle Weight Chart

Dump Truck Weight Chart

Average Axle Weight (kips), Axle Spacing (inches), and Number of Axle

Ask Us Cool Trailer Axle Spacing Diagram References

Truck Axle Spacing Chart

Vehicle Weight Regulations South Dakota Truck Information

Maximum Gross and Axle Weights Big Truck Guide

Axle types, spacing and weight configurations of the standard and MI

Mad Easy Load in a Dry Van Trailer Photos Falcon Stakint

4x2 TractorTrailer configuration for 50 Ton, 51 Ton, 52 Ton, 53 Ton

If Your Vehicle Is Overweight, You Will Need An Axle Spacing Report Number.

Configure The Optimal Vehicle For Your Customer's Needs.

Hanger Spacing Is Important, But You Will Also Want To Make Sure That The Axles Are Positioned.

W (Actual Weight) = 17,000 + 17,000 + 17,000 + 17,000 = 68,000 Lb.

Related Post: