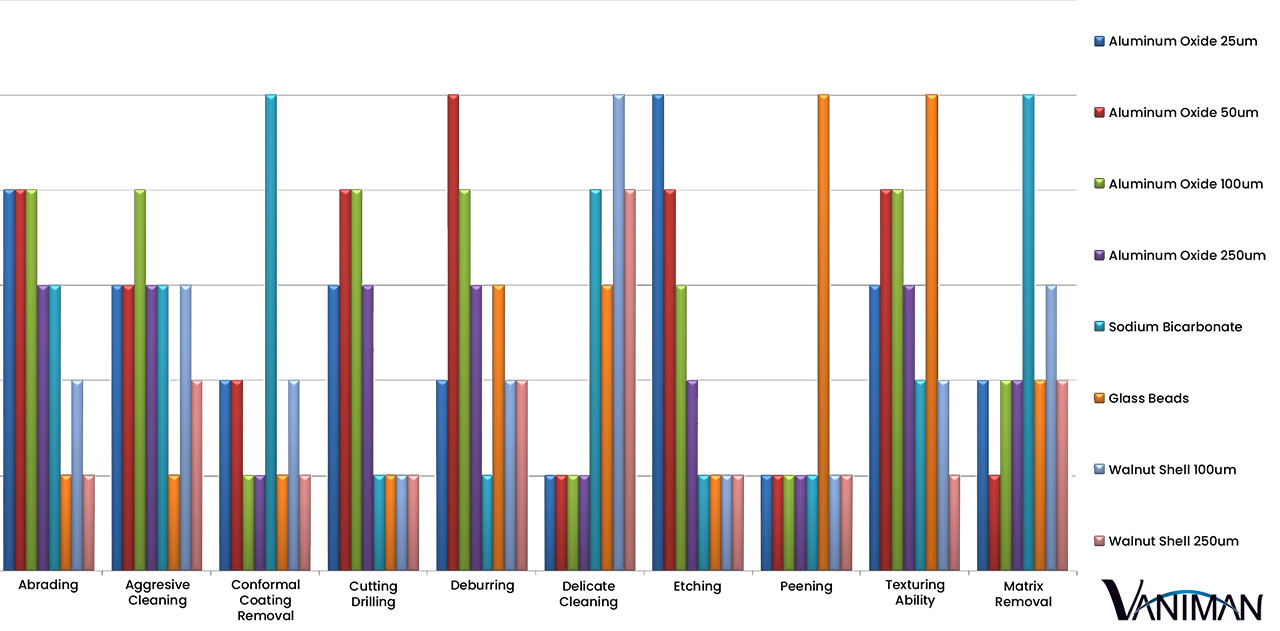

Abrasive Blast Media Chart

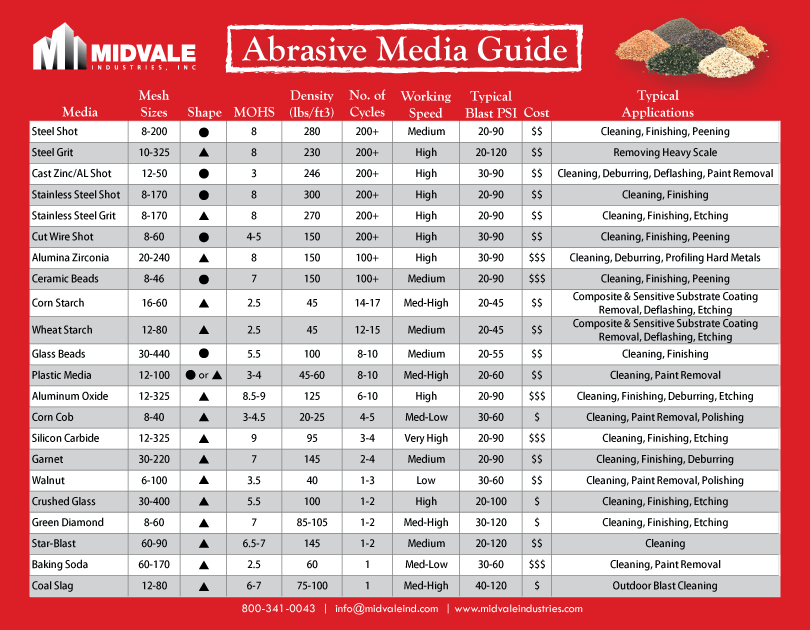

Abrasive Blast Media Chart - Web handy sandblasting grit conversion chart for grit size, uss mesh, microns, and inches. This means they can be collected and reused via a reclaiming system, usually in an enclosed cabinet. Web the below charts show a few types of abrasive used in dry media blasting. What is glass bead blasting? Web airblast favours two types of plastic media: As a general rule, the blaster should use the finest abrasive necessary to attain the required surface preparation characteristics. Whichever abrasive you choose, the following matters are important. Web engineering abrasive blasting solutions tailored to your needs. The more particles in the stream, the more work is accomplished in the same time. Web an abrasive blast media, by definition, are the particles of solid material that cause abrasion and erosion when impacted onto a target material, and there are a lot to choose from! This means they can be collected and reused via a reclaiming system, usually in an enclosed cabinet. Glass bead blasting is a versatile approach to abrasive media blasting that offers an attractive satin finish and works for a variety of purposes. Web use our grit blasting size chart for easy conversions! Web engineering abrasive blasting solutions tailored to your needs.. The right choice of abrasive is crucial to ensure the most successful outcome possible. Media particles are not in scale to one another) here are some of them and their benefits. Type v and type ii. As a general rule, the blaster should use the finest abrasive necessary to attain the required surface preparation characteristics. Web abrasive blasting (aka media. Media particles are not in scale to one another) here are some of them and their benefits. Web airblast favours two types of plastic media: As a general rule, the blaster should use the finest abrasive necessary to attain the required surface preparation characteristics. Web handy sandblasting grit conversion chart for grit size, uss mesh, microns, and inches. This chart. Lower numbers mean larger, while higher numbers mean the particles are more fine. This means they can be collected and reused via a reclaiming system, usually in an enclosed cabinet. As a general rule, the blaster should use the finest abrasive necessary to attain the required surface preparation characteristics. Web the below charts show a few types of abrasive used. Type v and type ii. The chart below details some of these differences and the anticipated results you can achieve. Glass bead blasting is a versatile approach to abrasive media blasting that offers an attractive satin finish and works for a variety of purposes. The right choice of abrasive is crucial to ensure the most successful outcome possible. This chart. In addition to the standard brown, aluminum oxide is available in 99.5% pure white grades. Web abrasives that don't break up easily have low friability and are usually recyclable. As a general rule, the blaster should use the finest abrasive necessary to attain the required surface preparation characteristics. A fine abrasive will give you more impacts per volume. Web the. The more particles in the stream, the more work is accomplished in the same time. Glass bead blasting is a versatile approach to abrasive media blasting that offers an attractive satin finish and works for a variety of purposes. Whichever abrasive you choose, the following matters are important. Easily see microns to grit size. Web your abrasive blasting media guide: The blasting media, the blasting installation, the blasting process, the product to be blasted and clear specifications of, among other things, the roughness to be achieved. Web abrasives that don't break up easily have low friability and are usually recyclable. Web airblast favours two types of plastic media: Web your abrasive blasting media guide: Web use our grit blasting size. Media particles are not in scale to one another) here are some of them and their benefits. Crushed glass is mostly used as abrasive media for outdoor dry blasting. The right choice of abrasive is crucial to ensure the most successful outcome possible. E ach abrasive has a listed hardness value, surface profile, surface removal ability, and velocity (if the. Web an abrasive blast media, by definition, are the particles of solid material that cause abrasion and erosion when impacted onto a target material, and there are a lot to choose from! Whichever abrasive you choose, the following matters are important. = manufactured *consult osha regulations before using silica sand as. Many suppliers use recycled beer and wine bottles to. This chart will help you understand the differences among many common types of abrasive blast media. This means they can be collected and reused via a reclaiming system, usually in an enclosed cabinet. Web there are 5 things of enormous importance for the end result of your blasting process: Web abrasives used in the blasting industry. Type v and type ii. Web in this comprehensive guide, we will navigate the intricacies of abrasive media, exploring different types of blast media, factors to consider when selecting the most suitable one for your needs, and how to estimate the quantity needed for your specific project. Web airblast favours two types of plastic media: Web use our grit blasting size chart for easy conversions! The right choice of abrasive is crucial to ensure the most successful outcome possible. As a general rule, the blaster should use the finest abrasive necessary to attain the required surface preparation characteristics. Web handy sandblasting grit conversion chart for grit size, uss mesh, microns, and inches. Each type of media has its unique properties and applications, making it crucial to select the appropriate one for each project. Both are considered light abrasives at the recommend psi values. Glass bead blasting is a versatile approach to abrasive media blasting that offers an attractive satin finish and works for a variety of purposes. E ach abrasive has a listed hardness value, surface profile, surface removal ability, and velocity (if the blasting media travels at a high speed or a low speed from the blast pot's compressed air). Web abrasives that don't break up easily have low friability and are usually recyclable.

Choosing the Right Blast Media for Abrasive Blasting

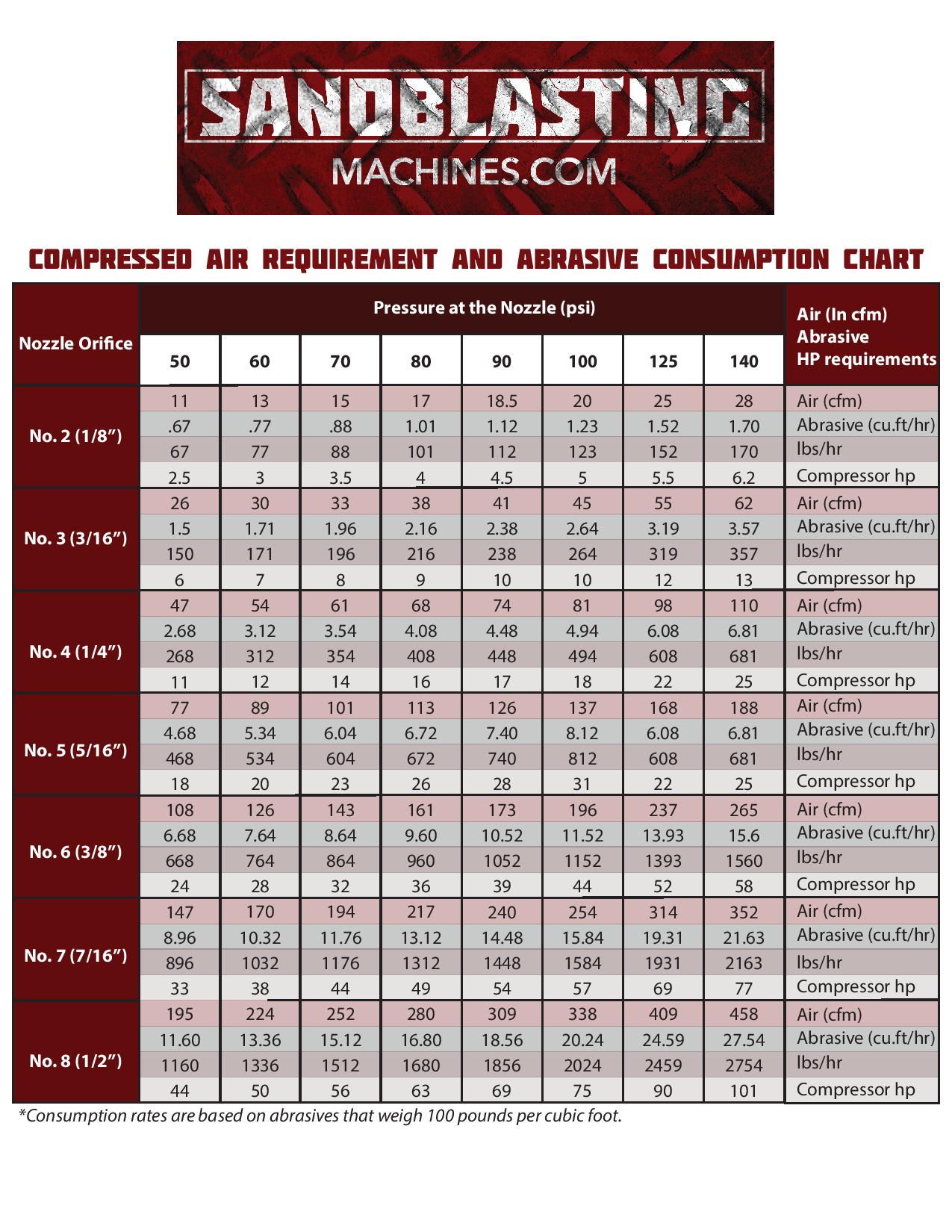

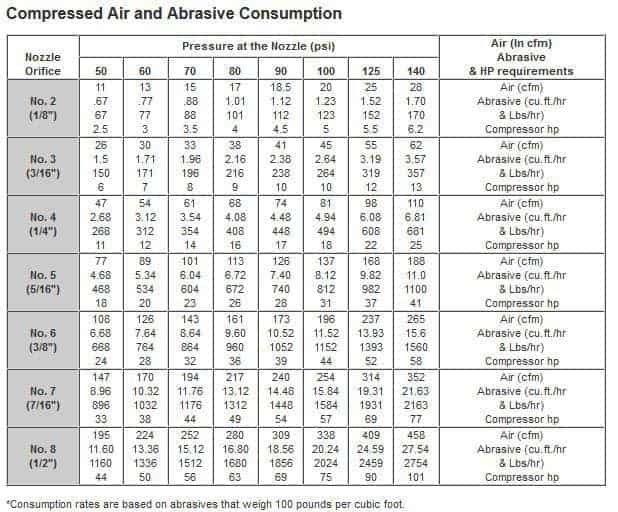

Understanding Sandblasting Compressor Size Requirements Sandblasting

Shot Blasting Abrasive Stainless Steel Abrasive Media

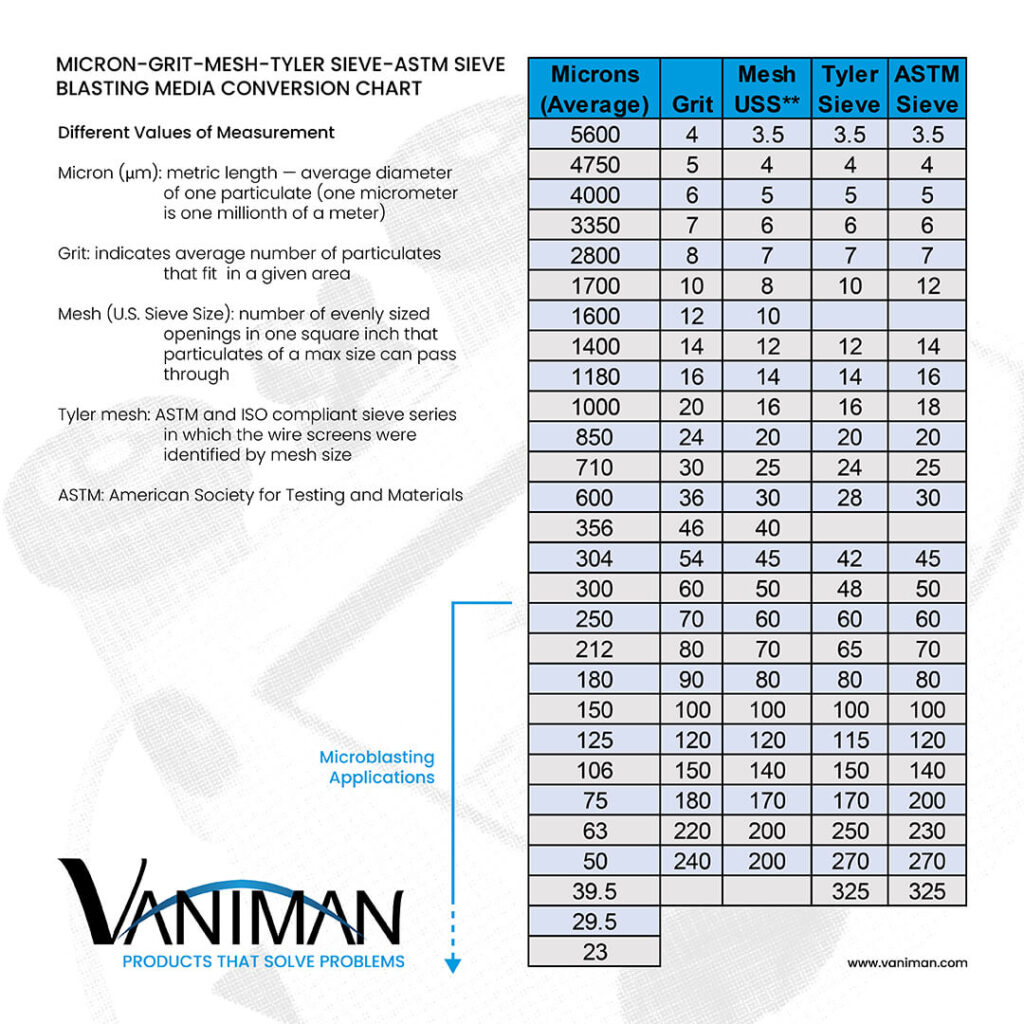

Abrasive Sandblasting Media Grit to Micron Conversion Calculator

Choosing The Right Blast Media For Abrasive Blasting

Sand Blast Media Chart A Visual Reference of Charts Chart Master

7 Things You Should Be Doing When Sandblasting Midvale Industries

Abrasive Sandblasting Media Shop & Quick Guide

Wetblasting Media DanaRidge Wetblast Abrasive Systems

Abrasive Blasting Media Guide Which Blasting Media Is Best?

In Addition To The Standard Brown, Aluminum Oxide Is Available In 99.5% Pure White Grades.

Web Abrasive Blasting (Aka Media Blasting) Is A Quick And Effective Way To Remove Layers Of Paint Or Years Of Corrosion.

Crushed Glass Is Mostly Used As Abrasive Media For Outdoor Dry Blasting.

= Manufactured *Consult Osha Regulations Before Using Silica Sand As.

Related Post: