7018 Welding Rod Amperage Chart

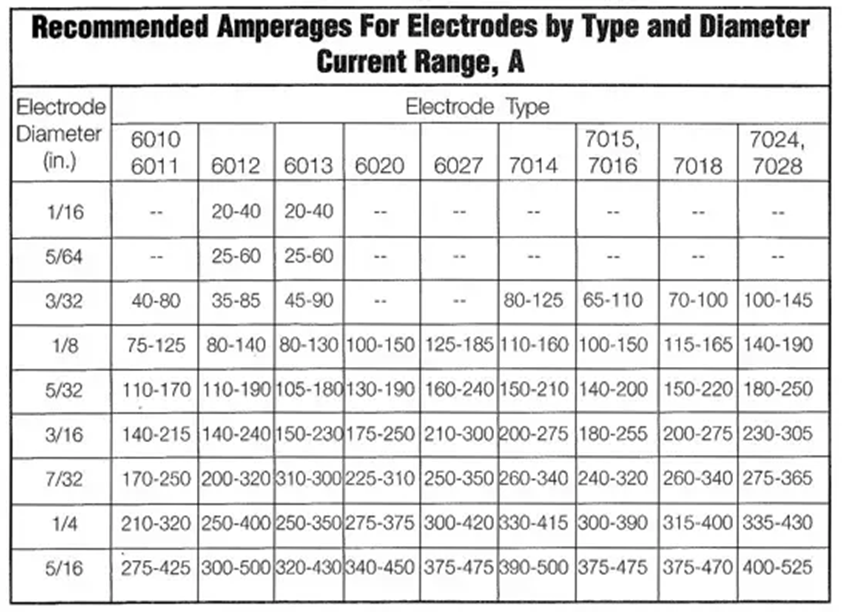

7018 Welding Rod Amperage Chart - Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Once you determine these three main variables, you can set your welding machine and start laying a weld. Excellent wetting in the toes allowing for less hold times. 6010 and 6011 are virtually the same rod. 7018 welding rod settings for 5/32″ 7018 welding rod The third digit indicates the welding position. Web november 21, 2022 by sandeep kumar. Diameter (inches) diameter (mm) 6010/6011. Soft arc for ease of puddle manipulation. Web to gain the best results, it is always important to follow the manufacturer’s recommendations for operating parameters for the given e7018 stick electrode diameter. Web as a thump rule, welding amperage for e7018 is 70 ampere to 200 ampere. No intentional addition of zinc for moisture resistance. As a general rule of thumb, you should increase the amperage by 30amps for every 1/32 increase in diameter. Ac or dc, reverse polarity 60,000 psi tensile strength all position electrode. ‘m’ represents stick welding rod to. E7018m welding electrode is a low hydrogen, iron powder type electrode. 86,000 yield strength (psi) 58,000. How to choose welding rod amperage. Web if you aren’t sure which type of electrode to buy then look at our comparison of 6010 vs 6011 vs 6013 vs 7018 vs 7024. 6010 and 6011 are virtually the same rod. Welding with ac polarity needs high welding amperage compared to dcep when using e7018 welding rod. Excellent wetting in the toes allowing for less hold times. E6010 and e6011 size and amperage chart. These guidelines can vary between different manufacturers so always check the manufacturer’s guidelines if possible. This page serves as a point of reference and a guide for. No intentional addition of zinc for moisture resistance. E6010 and e6011 size and amperage chart. Web table of contents. This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. Web electrode amperage chart | types and thicknesses; (2 of 2) copyright © 2013 lawson products, inc. Diameter (inches) diameter (mm) 6010/6011. If you are looking for a reliable and strong welding rod to help complete your next big project, 7018 welding rods are perfect. This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get. 7018 welding rod settings for 5/32″ 7018 welding rod The below tables gives the recommended welding amperage for e7018 electrode diameter 3/32, 1/8, 5/32, 3/16, 7/32 &. Approximations for these parameters are as follows: Web as the welding rod’s diameter increases so do the amperage requirement. This page serves as a point of reference and a guide for selecting the. You will also get the required polarity, position, and other related information. 7018 welding rod settings for 5/32″ 7018 welding rod Web may 23, 2023. 6010 and 6011 are virtually the same rod. This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when. Diameter (inches) diameter (mm) 6010/6011. Ac or dc, reverse polarity 60,000 psi tensile strength all position electrode. How to choose welding rod amperage. Web the document is an electrode amperage chart listing welding electrode types, diameters in both inches and millimeters, and recommended amperage ranges. E6010 and e6011 size and amperage chart. Once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. The third digit indicates the welding position. Additionally, we made the most complete stick welding rod chart pdf on the internet with over 220 electrodes. The below tables gives the recommended welding. 6013 welding rod amperage chart; Web if you aren’t sure which type of electrode to buy then look at our comparison of 6010 vs 6011 vs 6013 vs 7018 vs 7024. How to choose welding rod amperage. Ac or dc, reverse polarity 60,000 psi tensile strength all position electrode. Web as the welding rod’s diameter increases so do the amperage. Once you determine these three main variables, you can set your welding machine and start laying a weld. What do welding rod size numbers mean? Both welding electrodes have a violent digging arc, they are fast freeze, all position rods, the slag is thin and flaky and the penetration is deep. Soft arc for ease of puddle manipulation. Web may 23, 2023. The below tables gives the recommended welding amperage for e7018 electrode diameter 3/32, 1/8, 5/32, 3/16, 7/32 &. This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. The last digit of “ 8 ” indicates the coating type or materials, penetration, and the types of current that can be employed for the electrode. 86,000 yield strength (psi) 58,000. What are the common sizes of tig welding rods? E7018m welding electrode is a low hydrogen, iron powder type electrode. Welding rod sizes and base metal thickness chart. Approximations for these parameters are as follows: In general, the 7018 rod is used with currents up to 225 amps. Web electrode amperage chart | types and thicknesses; 7018 welding rod settings for 5/32″ 7018 welding rod

7018 Welding Rods Amperage Chart WOW WELDER

Welding Rod Amperage Chart Pdf

The ultimate guide to welding rod sizes and classifications, including

Welding Rod Amp Chart

ضبط الامبير للحام القواعد الذهبية فى اللحام القاعدة الرابعةWelding

Tig Welding Amperage Chart

7018 Welding Rod Amperage Chart

7018 Welding Rod Amperage Chart

What are a reasonable rods to use ? Welding Site

Welding

You Can Get A Lot Of Information By Just Looking At The Series.

The Table Is Published In Aws A5.1 Specification.

Web Setting The Amperage On A Welding Machine, Whether Stick (Smaw), Mig (Gmaw) (*Typically Uses Voltage Setting), Or Tig (Gtaw), Depends On Some Key Variables Such As Application And Base Material, Welding Process, And Electrode.

Web Table Of Contents.

Related Post: