4140 Tempering Chart

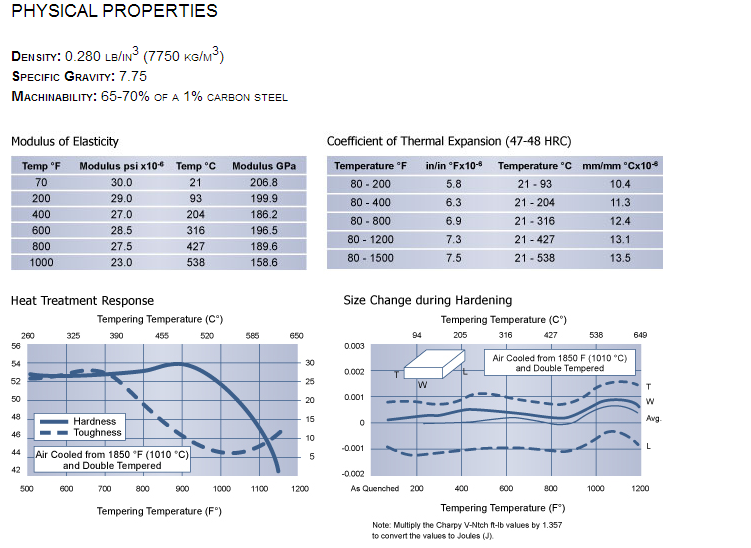

4140 Tempering Chart - Heat at a rate not exceeding 400°f per hour (222°c per hour) to 1500°f (816°c), and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; The hardness of the steel can be increased if it has a lower tempering temperature. 4140 ht can also be surface hardened to increase wear resistance. Hold at temperature for 1 hour per inch (25.4 mm) of thickness, 2 hours minimum, then air cool to ambient temperature. For example, a tensile strength of 225 ksi can be achieved by tempering at 316°c (600°f), and tensile strength of 130 ksi can be. Temper ½ to 2 hours at between 175 and 230°c, while for yield strength below Select tempering temperatures according to the required mechanical properties (refer to tempering curve). Good elongation with quality impact & abrasion resistance. For yield strengths above 1380mpa: Characterised by high strength and good impact properties with good machinability, but low weldability. Hold for at least 30 minutes, preferably more. Temper ½ to 2 hours at between 175 and 230°c, while for yield strength below Web the specification defines the requirements for aisi 4140 hot rolled crmo bars hardened and tempered to meet 80ksi minimum yield, 22hrc maximum, in line with nace mr0175/iso 15156 or 110 ski minimum yield, 36 hrc maximum.. Good elongation with quality impact & abrasion resistance. Holding in the temperature range 230 to 370°c should be avoided due to possible temper embrittlement (“blue brittleness”). Strength properties of the joint will not be the same as the base metal. The hardness of the steel can be increased if it has a lower tempering temperature. Temper ½ to 2 hours. Aisi 4140 steel stockholders and suppliers, delivering to the whole of the uk. The hardness of the steel can be increased if it has a lower tempering temperature. Web we also ask that you refer to matweb's terms of use regarding this information. Oil quenched from 1600°f • tempered 4 hours (section size — 4” x 4”) note: Key properties. Heat at a rate not exceeding 400°f per hour (222°c per hour) to 1500°f (816°c), and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; 4140 alloy steel boasts impressive hardness, making it suitable for applications requiring high. Web aisi 4140 is capable of resisting creep in temperatures up to 538°c (1000°f) and maintaining its properties even. The hardness of the steel can be increased if it has a lower tempering temperature. Web parts should be welded in the hardened and tempered condition. Aisi 4140 ph is used in applications requiring good machinability, good tensile strength, and where parts would be subject to unacceptable distortion if heat treated after machining. For yield strengths above 1380mpa: 4140 ht. Typical analysis is shown in the chart below: Holding in the temperature range 230 to 370°c should be avoided due to possible temper embrittlement (“blue brittleness”). Hold at temperature for 1 hour per inch (25.4 mm) of thickness, 2 hours minimum, then air cool to ambient temperature. For yield strengths above 1380mpa: Automotive parts, armament components, jigs, fixtures, tooling, gears,. Material 4140 forging temperature is about 1232 °c (2250 °f). Holding in the temperature range 230 to 370°c should be avoided due to possible temper embrittlement (“blue brittleness”). Characterised by high strength and good impact properties with good machinability, but low weldability. Users viewing this material also viewed the following: The hardness of the steel can be increased if it. Characterised by high strength and good impact properties with good machinability, but low weldability. Automotive parts, armament components, jigs, fixtures, tooling, gears, sprockets, wrenches &. For yield strengths above 1380mpa: Web parts should be welded in the hardened and tempered condition. Web sae 4140 steel is a versatile and widely used alloy steel known for its impressive strength and toughness. Select tempering temperatures according to the required mechanical properties (refer to tempering curve). Typical analysis is shown in the chart below: Remove the metal from the furnace and allow to cool in ambient air. Web select tempering temperature according to the required mechanical properties (refer to tempering curve). Tempering reduces the brittleness of the steel, improves its toughness, and relieves. 4140 alloy steel boasts impressive hardness, making it suitable for applications requiring high. Web aisi 4140 is capable of resisting creep in temperatures up to 538°c (1000°f) and maintaining its properties even after long exposure at comparatively high working temperatures. Web sae 4140 steel is a versatile and widely used alloy steel known for its impressive strength and toughness. Web. 4140 tfht flats are readily available, and can be surface ground to tool steel tolerances. Remove the metal from the furnace and allow to cool in ambient air. 4140 ht can also be surface hardened to increase wear resistance. Web aisi 4140 is capable of resisting creep in temperatures up to 538°c (1000°f) and maintaining its properties even after long exposure at comparatively high working temperatures. Web aisi 4140 alloy steel can be tempered at 205 to 649°c (400 to 1200°f) depending upon the desired hardness level. Iso 9001 certifie usa s british assessment. The hardness of 4140 steel varies based on the toughness temperature and usually in the range of 217 hb to 241 hb. Tempering reduces the brittleness of the steel, improves its toughness, and relieves residual stresses. Automotive parts, armament components, jigs, fixtures, tooling, gears, sprockets, wrenches &. Web the specification defines the requirements for aisi 4140 hot rolled crmo bars hardened and tempered to meet 80ksi minimum yield, 22hrc maximum, in line with nace mr0175/iso 15156 or 110 ski minimum yield, 36 hrc maximum. Good elongation with quality impact & abrasion resistance. It belongs to the aisi/sae a29 standard. Here we talk about different aspects of sae 4140, including its chemical composition, mechanical properties, equivalent materials, and applications. For example, a tensile strength of 225 ksi can be achieved by tempering at 316°c (600°f), and tensile strength of 130 ksi can be. Tempering is the final step in the heat treatment process. Characterised by high strength and good impact properties with good machinability, but low weldability.eficiencia De tormenta en términos de tempering 4140 steel filtrar

4140 heat treat chart Conomo.helpapp.co

(PDF) Effect of Heat Treatment on the Fracture Toughness of AISI 4140 Steel

Temperature, cooling rate, time curves for 4140 steel quenched in

4140 Tempering Chart

Table 1 from Austempering Heat Treatment of AISI 4340 Steel and

4140 Steel Rockwell Hardness Chart Best Picture Of Chart

4140 steel harden/temper suggestions... Metal and Metallurgy

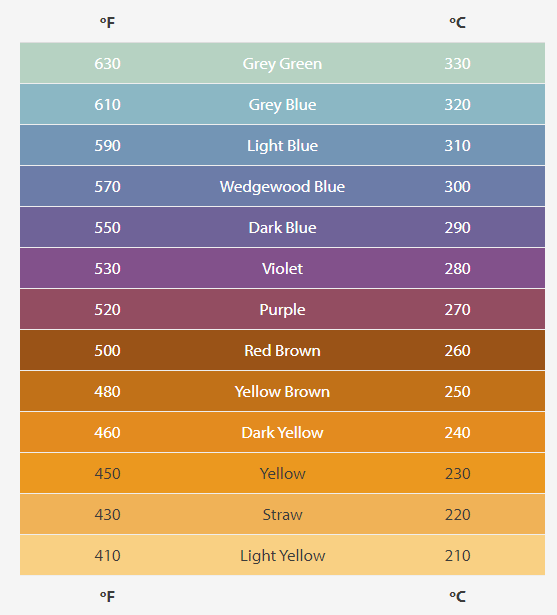

Steel Tempering Temperatures Colour Chart NIFTY ALLOYS LLC

4140 Alloy Steel 1.7225 SCM440 42CrMo4 OTAI Special Steel

For Yield Strengths Above 1380Mpa:

Web Parts Should Be Welded In The Hardened And Tempered Condition.

Strength Properties Of The Joint Will Not Be The Same As The Base Metal.

Click Here To View All The Property Values For This Datasheet As They Were Originally Entered Into Matweb.

Related Post: