4140 Hardness Chart

4140 Hardness Chart - Applications | specifications | mechanical and chemical data | tolerances. Aisi 4140 has higher yield and fatigue strength, better through hardening and superior impact properties compared to plain carbon steels like 1045. These elements form hard carbide particles and improve the material’s wear resistance and toughness. 0.283 lb/in3 (7.85 g/cm3) melting range: A low allow chromium molybdenum (crmo) steel. Automotive parts, armament components, jigs, fixtures, tooling, gears, sprockets, wrenches &. With a robust yield strength, 4140 steel can withstand heavy loads and stresses, ensuring reliable performance in demanding environments. Forging material 4140 forging temperature is about 1232 °c (2250 °f). Aisi 4140 steel has good wear resistance due to its high carbon content and the addition of chromium and molybdenum to its composition. Chromium, molybdenum steel for applications requiring high tensile strength and toughness values, in particular in medium and large cross sections in the quenched and tempered condition. Applications | specifications | mechanical and chemical data | tolerances. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength. Aisi 4140 has higher yield and fatigue strength, better through hardening and superior impact properties compared to plain carbon steels like 1045. This inherent hardness makes it an attractive choice for numerous applications where strength and durability. Aisi 4140 has higher yield and fatigue strength, better through hardening and superior impact properties compared to plain carbon steels like 1045. Applications | specifications | mechanical and chemical data | tolerances. Chromium, molybdenum steel for applications requiring high tensile strength and toughness values, in particular in medium and large cross sections in the quenched and tempered condition. This alloying. Brinell hardness of around 197. The molybdenum additions prevent the steel from being susceptible to temper brittleness. These properties can vary depending on the treatment processes like qt or annealig and normalizing. This alloy has high strength, high fatigue strength, toughness, torsional strength, and impact and abrasion resistance. 4140 ht can also be surface hardened to increase wear resistance. This inherent hardness makes it an attractive choice for numerous applications where strength and durability are paramount. Web aisi 4140 steel, normalized at 870°c (1600°f), air cooled, 25 mm (1 in.) round. Web aisi 4140 steel typically boasts a prehard hardness ranging from 28 to 32 hrc (rockwell hardness scale c). Aisi 4140 steel has good wear resistance due to. Good elongation with quality impact & abrasion resistance. Aisi 4140 has higher yield and fatigue strength, better through hardening and superior impact properties compared to plain carbon steels like 1045. At its core, 4140 annealed steel is an alloy composed of chromium, molybdenum, and carbon. Typical applications include connection rods, collets, conveyor pins, gears, stem assemblies, pump shafts and tool. Composition of 4140 annealed steel. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. Typical applications include connection rods, collets, conveyor pins, gears, stem assemblies, pump shafts and tool holders. These elements form hard carbide particles and improve the material’s wear resistance and toughness. These conversion charts are provided for guidance only. The following datasheet gives an overview of aisi 4140 alloy steel. This alloying combination imparts unique properties to the steel, making it suitable for a wide range of applications. Brinell hardness of around 197. Aisi 4140 steel has good wear resistance due to its high carbon content and the addition of chromium and molybdenum to its composition. Web this table. The following datasheet gives an overview of aisi 4140 alloy steel. Web key properties include: This alloy has high strength, high fatigue strength, toughness, torsional strength, and impact and abrasion resistance. The desirable properties of the aisi 4140 include superior toughness, good ductility and good wear resistance in the quenched and tempered condition. Web aisi 4140 steel, normalized at 870°c. Web aisi 4140 steel typically boasts a prehard hardness ranging from 28 to 32 hrc (rockwell hardness scale c). It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength. 4140 alloy steel boasts impressive hardness, making it suitable for applications requiring high durability and resistance to abrasion. This inherent hardness makes it an attractive choice for numerous. Web aisi 4140 steel, normalized at 870°c (1600°f), air cooled, 25 mm (1 in.) round. Lss 4142ht is a similar steel which is sold prehardened to 28 to 32 hrc (269 to 302 hbw). Composition of 4140 annealed steel. With a robust yield strength, 4140 steel can withstand heavy loads and stresses, ensuring reliable performance in demanding environments. Applications |. These elements form hard carbide particles and improve the material’s wear resistance and toughness. This alloy has high strength, high fatigue strength, toughness, torsional strength, and impact and abrasion resistance. This inherent hardness makes it an attractive choice for numerous applications where strength and durability are paramount. A low allow chromium molybdenum (crmo) steel. 0.283 lb/in3 (7.85 g/cm3) melting range: 4140 ht can also be surface hardened to increase wear resistance. Brinell hardness of around 197. At its core, 4140 annealed steel is an alloy composed of chromium, molybdenum, and carbon. The hardness of 4140 steel varies based on the toughness temperature and usually in the range of 217 hb to 241 hb. Good elongation with quality impact & abrasion resistance. Automotive parts, armament components, jigs, fixtures, tooling, gears, sprockets, wrenches &. The right hand column show an approximate equivalent tensile strength. Web key properties include: 29.7 x106psi (205 gpa) magnetic permeability: Typical applications include connection rods, collets, conveyor pins, gears, stem assemblies, pump shafts and tool holders. 4140 alloy steel boasts impressive hardness, making it suitable for applications requiring high durability and resistance to abrasion.

4140 Steel Rockwell Hardness Chart Best Picture Of Chart

Hardness profiles of AISI 4140 steel, ion nitrided at 748 K for 1, 3, 8

4140 Steel Hardness Chart

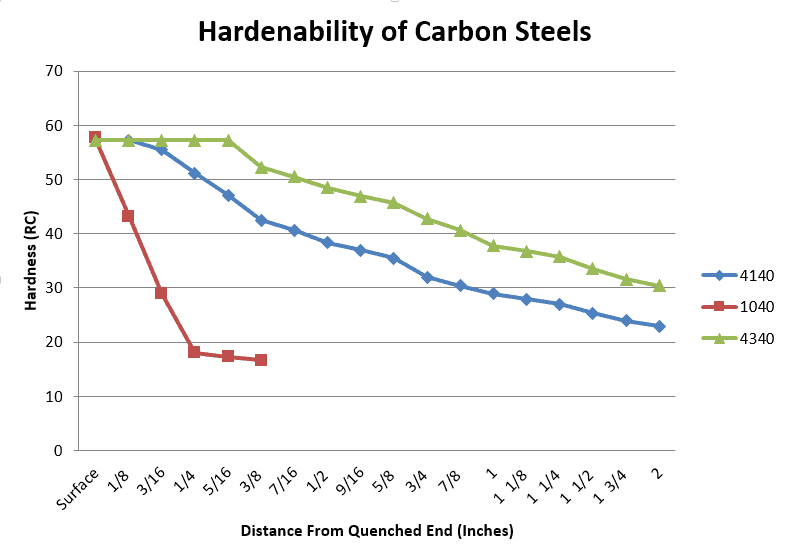

Hardenability Curve for 4140 Steel line chart made by Kylermixon plotly

4140 steel harden/temper suggestions... Metal and Metallurgy

Jominy standard curves for AISI 4140 steel (0.37 C; 0.77 Mn; 0.98

Hardenability of Steel In The Loupe

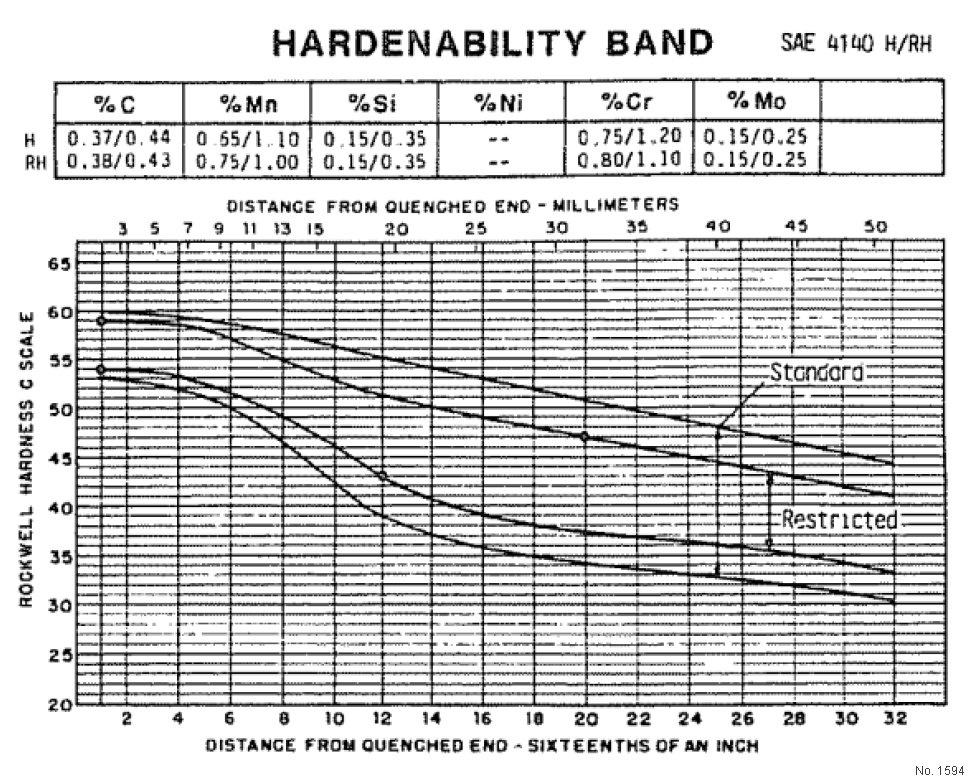

SAE 4140 H/RH Steel Hardenability Diagram

4140 Steel Rockwell Hardness Chart Best Picture Of Chart

4140 Hardening Chart

These Conversion Charts Are Provided For Guidance Only As Each Scales Uses Different Methods Of Measuring Hardness.

Specialty Steel Supply 19201 Circle.

It Has High Fatigue Strength, Abrasion And Impact Resistance, Toughness, And Torsional Strength.

Lss 4142Ht Is A Similar Steel Which Is Sold Prehardened To 28 To 32 Hrc (269 To 302 Hbw).

Related Post: