34 Emt 90 Degree Bend Deduction Chart

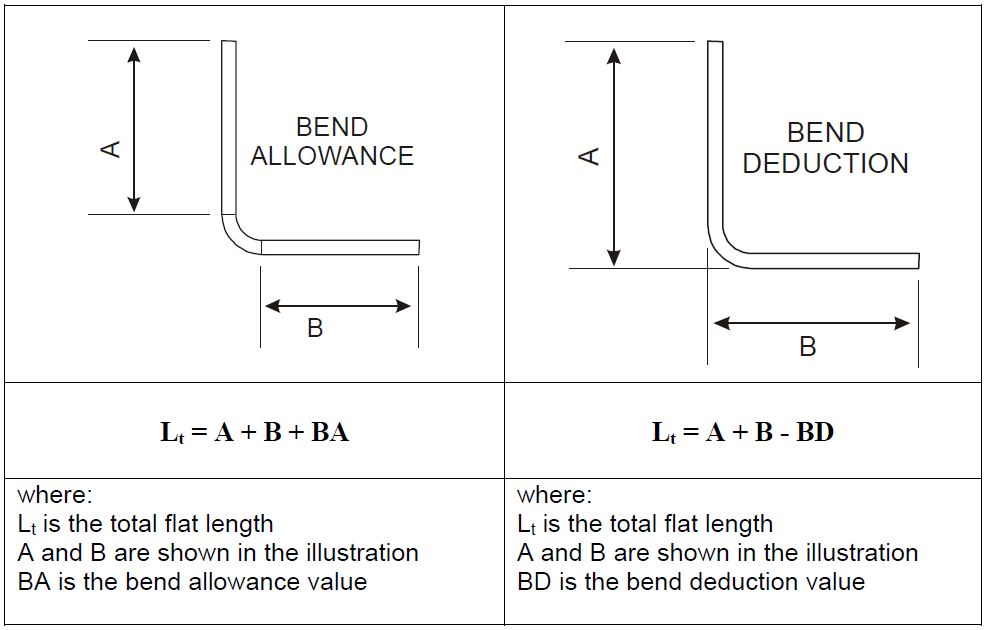

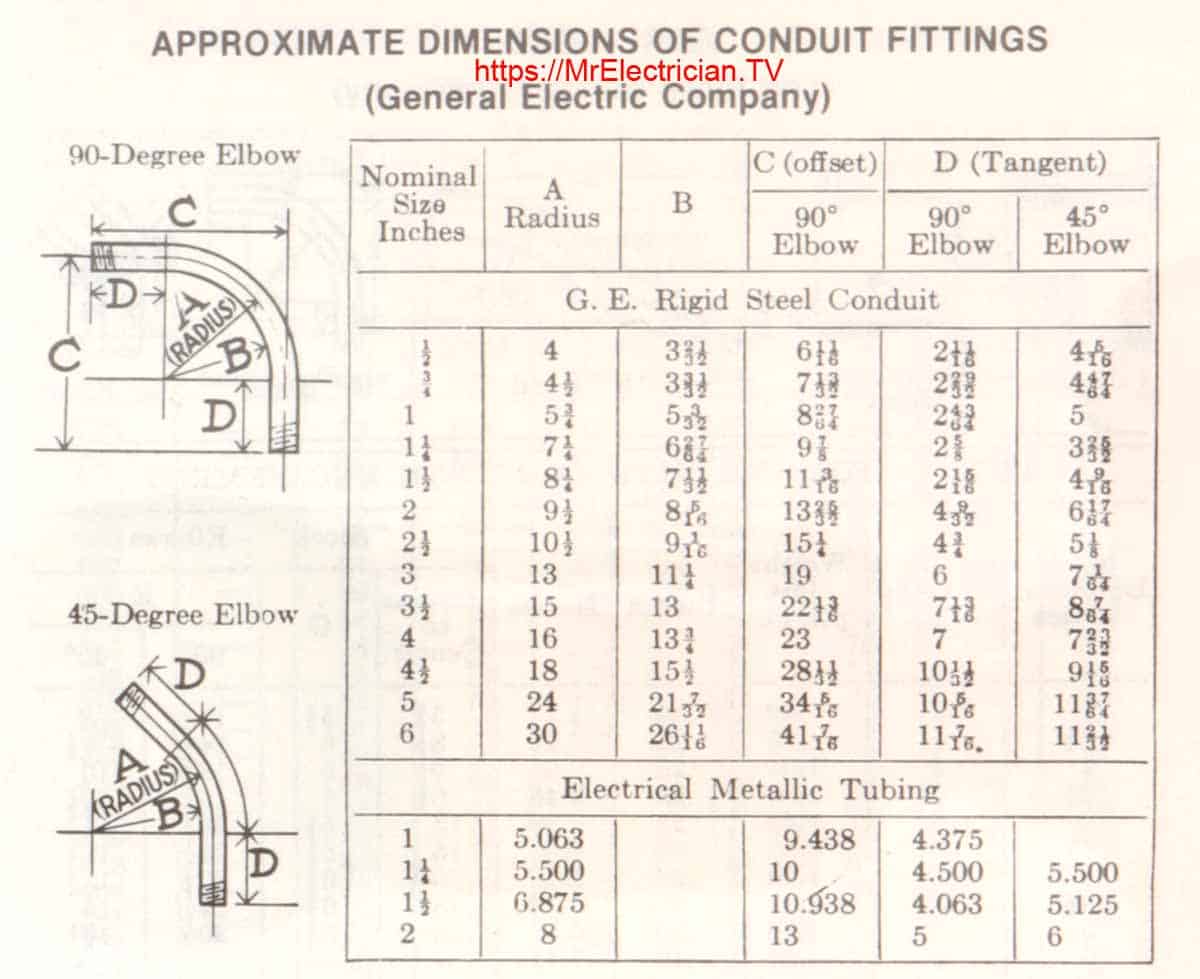

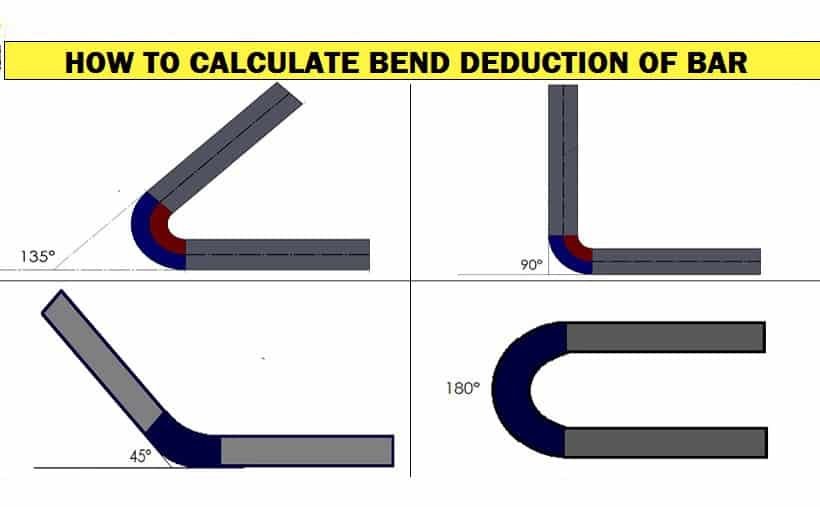

34 Emt 90 Degree Bend Deduction Chart - 90 95 100 105 110 115 120 125 130 135 140. The bend allowance describes the length of the. Deduction deduction deduction deduction deduction deduction. Table 1 measure and mark distance on the conduit from a fixed point (x), to the back of the 90° bend, point (y). Web as an example, to bend 3/4” emt conduit have a free end height of 8.5”, the table indicates to subtract 6” from the 8.5” which leave 2.5” from the end to bend up to make the mark. Obtain the characteristics of your material (thickness. Align (y) with (b or ★) on. Bend using 3/4 rigid two 45 deg. Web when the bending angle is 90°, the bending allowance formula can be simplified as follows: In this case 14” minus 6” = 8”. Web how to bend a 90˚ the 90 degree/right angle bend is possibly the most basic and common of bends, but there are several ways to do it. Obtain the characteristics of your material (thickness. The bend deduction formula takes into account the geometries of bending and the properties of your metal to determine the bend deduction. The bend allowance. Web when the bending angle is 90°, the bending allowance formula can be simplified as follows: Web to calculate bend allowance: Web bend deduction chart k factor 0.45 k factor 0.45 k factor 0.45 k factor 0.45 k factor 0.45 k factor 0.45 k factor 0.45 k factor 0.45. Web the bending chart provides an intuitive way to visualize the. Obtain the properties of the bend (bend radius, angle, and method used). B a = π 2 ( r + k × t) note: Obtain the characteristics of your material (thickness. Web as an example, to bend 3/4” emt conduit have a free end height of 8.5”, the table indicates to subtract 6” from the 8.5” which leave 2.5” from. Web when the bending angle is 90°, the bending allowance formula can be simplified as follows: Web in our example we’re going to be dealing with 1/2”, 3/4”, and 1” emt. Bend using 3/4 rigid two 45 deg. 90 95 100 105 110 115 120 125 130 135 140. Web bend deductions (bd), the amount of change in the material. Web in our example we’re going to be dealing with 1/2”, 3/4”, and 1” emt. 90 95 100 105 110 115 120 125 130 135 140. Deduction deduction deduction deduction deduction deduction. 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170. Mark the conduit 8” from the end. Web bend deductions (bd), the amount of change in the material between the flat and the formed material, are developed from mathematical formulas. Web = place mark on conduit at a stationary point at the back of the bender after bending 90 degree bend and enter value in the travel t cell in chart deduct = af length = l. 90 95 100 105 110 115 120 125 130 135 140. Line up the arrow on the bender. Web how to bend a 90˚ the 90 degree/right angle bend is possibly the most basic and common of bends, but there are several ways to do it. I have no issue with the. In this case 14” minus 6” = 8”. Obtain the properties of the bend (bend radius, angle, and method used). 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170. Web bend deductions (bd), the amount of change in the material between the flat and the formed material, are developed from mathematical formulas. Web the bend allowance and bend deduction are. Web the bending chart provides an intuitive way to visualize the effect of different parameters such as bend angle, radius, material thickness, etc. Web when the bending angle is 90°, the bending allowance formula can be simplified as follows: Bend until 90° bend is formed. Obtain the characteristics of your material (thickness. I have no issue with the. Web bend deductions (bd), the amount of change in the material between the flat and the formed material, are developed from mathematical formulas. 90 95 100 105 110 115 120 125 130 135 140. The bend deduction formula takes into account the geometries of bending and the properties of your metal to determine the bend deduction. Web = place mark. The bend deduction formula takes into account the geometries of bending and the properties of your metal to determine the bend deduction. Mark the conduit 8” from the end. Web to calculate bend allowance: Web how to bend a 90˚ the 90 degree/right angle bend is possibly the most basic and common of bends, but there are several ways to do it. Web bend deductions (bd), the amount of change in the material between the flat and the formed material, are developed from mathematical formulas. The bend allowance describes the length of the. Web the bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. Web = place mark on conduit at a stationary point at the back of the bender after bending 90 degree bend and enter value in the travel t cell in chart deduct = af length = l stub fc. Table 1 measure and mark distance on the conduit from a fixed point (x), to the back of the 90° bend, point (y). Web the bending chart provides an intuitive way to visualize the effect of different parameters such as bend angle, radius, material thickness, etc. 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170. 90 95 100 105 110 115 120 125 130 135 140. Obtain the properties of the bend (bend radius, angle, and method used). Web as an example, to bend 3/4” emt conduit have a free end height of 8.5”, the table indicates to subtract 6” from the 8.5” which leave 2.5” from the end to bend up to make the mark. Web when the bending angle is 90°, the bending allowance formula can be simplified as follows: In this case 14” minus 6” = 8”.

EMT Conduit Dimensions Chart

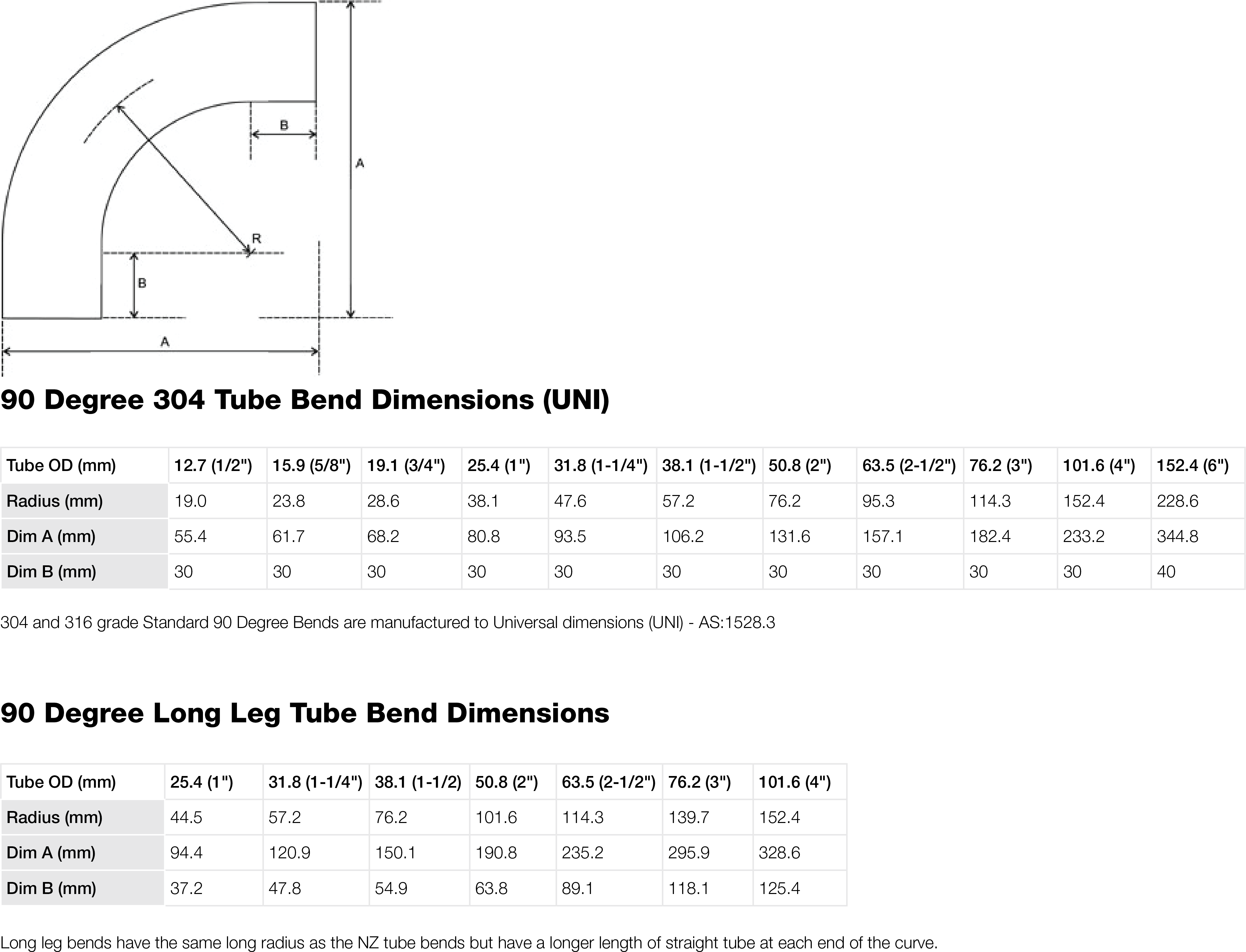

90 Deg Tube Bend Dimensions Anzor AU

Minimum tube bend radius chart vsamad

Nec Wire Fill Chart Emt Wiring Diagram

3/4 Emt 90 Degree Bend Deduction Chart

How To Bend Conduit change comin

Emt Conduit Dimensions Chart

3/4 Emt 90 Degree Bend Deduction Chart

Pipe Bending Deduction Chart

3/4 Emt 90 Degree Bend Deduction Chart

Obtain The Characteristics Of Your Material (Thickness.

Web Bend Deduction Chart K Factor 0.45 K Factor 0.45 K Factor 0.45 K Factor 0.45 K Factor 0.45 K Factor 0.45 K Factor 0.45 K Factor 0.45.

Bend Until 90° Bend Is Formed.

Web In Our Example We’re Going To Be Dealing With 1/2”, 3/4”, And 1” Emt.

Related Post: